Combined tunnel computer car washing machine

A tunnel-type and combined technology, which is applied in the direction of electrical components, vehicle exterior cleaning devices, casings/cabinets/drawer components, etc., and can solve the problem of internal operation panel damage, inconvenient cleaning, and foreign objects such as rainwater and dust falling easily Problems such as entering into the panel groove, achieving high stability and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

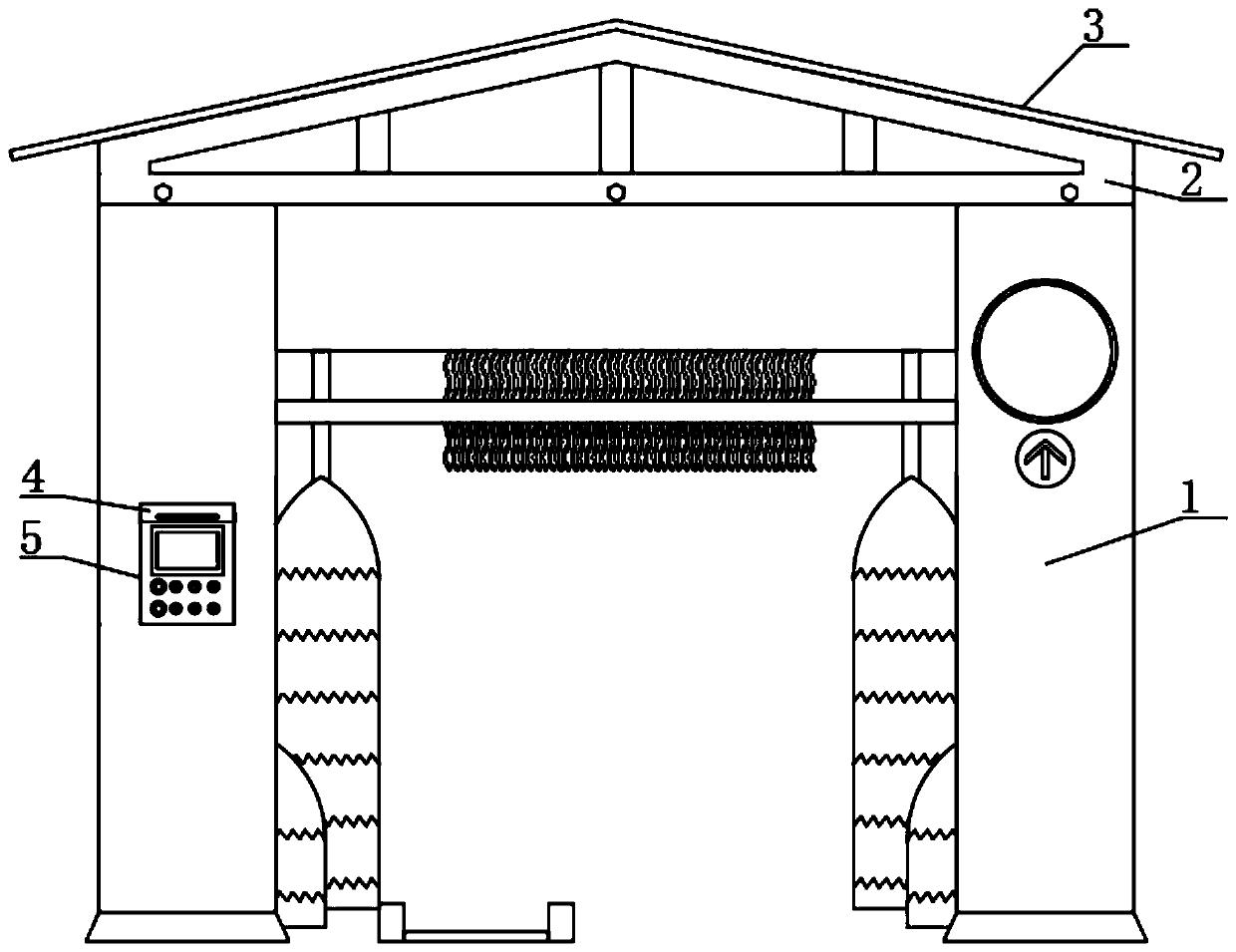

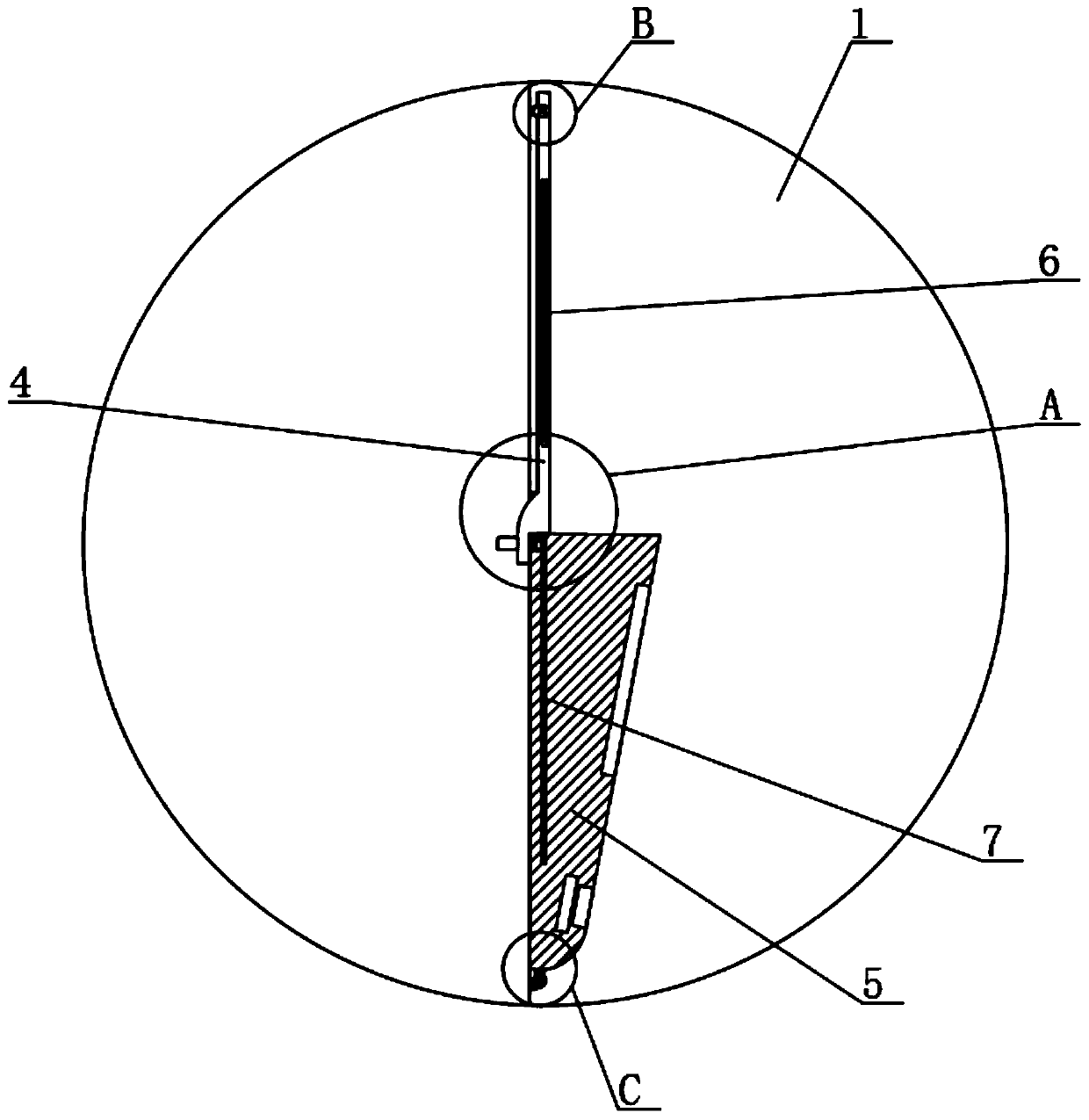

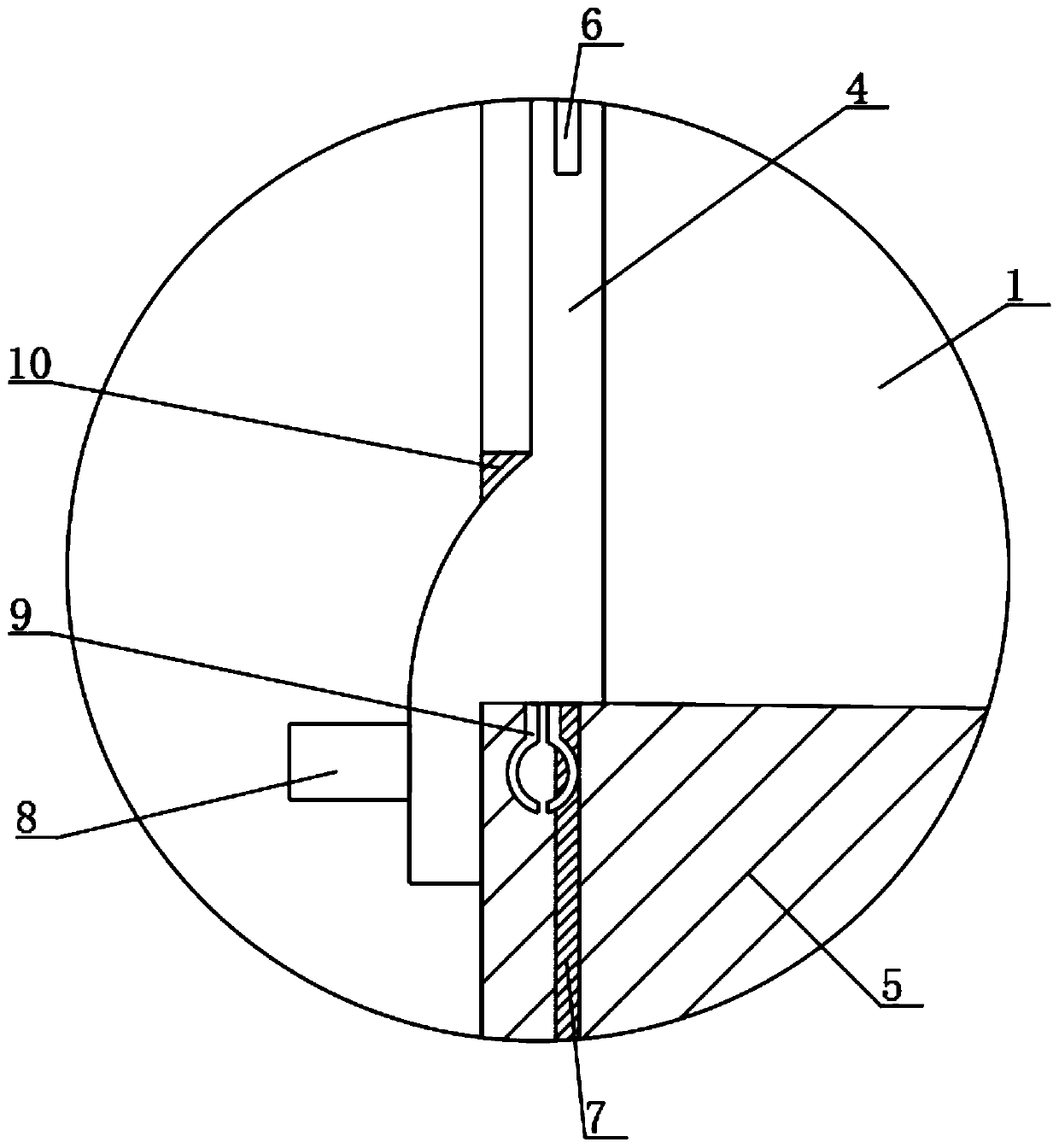

[0025] see Figure 1 to Figure 5 , the present invention provides a technical solution: a combined tunnel-type computerized car washing machine, comprising a frame 1 and a scaffold 2 arranged on the top of the frame 1, the top surface of the scaffold 2 is welded and fixed with a ceiling 3, and the frame 1 A panel groove 5 is opened on the front surface of the panel groove 5, and an operation panel is arranged on the inner side of the panel groove 5, an L-shaped plate groove 10 is opened on the top of the panel groove 5, and an L-shaped sealing plate 4, L-shaped plate groove 10 is arranged inside the L-shaped plate groove 10. The width of the shape sealing plate 4 is consistent with the width of the panel groove 5, and the both sides surfaces of the L shape sealing plate 4 are all provided with integral side sliding strips 6, and the inner wall of the L shape plate groove 10 is provided with two and side sliding bars. The side chute 7 corresponding to the bar 6, the side chute ...

Embodiment 2

[0030] see Figure 1 to Figure 7 , the present invention provides a technical solution: a combined tunnel-type computerized car washing machine, comprising a frame 1 and a scaffold 2 arranged on the top of the frame 1, the top surface of the scaffold 2 is welded and fixed with a ceiling 3, and the frame 1 A panel groove 5 is opened on the front surface of the panel groove 5, and an operation panel is arranged on the inner side of the panel groove 5, an L-shaped plate groove 10 is opened on the top of the panel groove 5, and an L-shaped sealing plate 4, L-shaped plate groove 10 is arranged inside the L-shaped plate groove 10. The width of the shape sealing plate 4 is consistent with the width of the panel groove 5, and the both sides surfaces of the L shape sealing plate 4 are all provided with integral side sliding strips 6, and the inner wall of the L shape plate groove 10 is provided with two and side sliding bars. The side chute 7 corresponding to the bar 6, the side chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com