Attapulgite conveying device beneficial for dumping

A technology of attapulgite soil and transportation device, which is applied in the directions of transportation and packaging, multi-axis trolleys, trolleys, etc., can solve problems such as inconvenience in operation, and achieve the effects of avoiding waste, avoiding dumping, and providing good support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

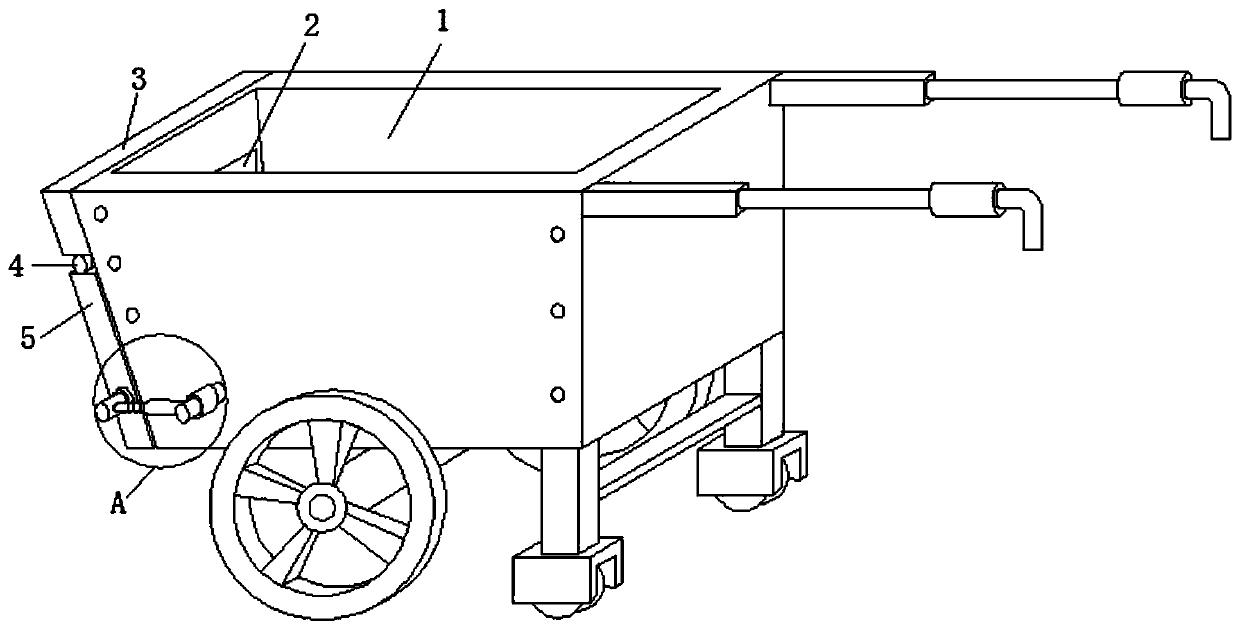

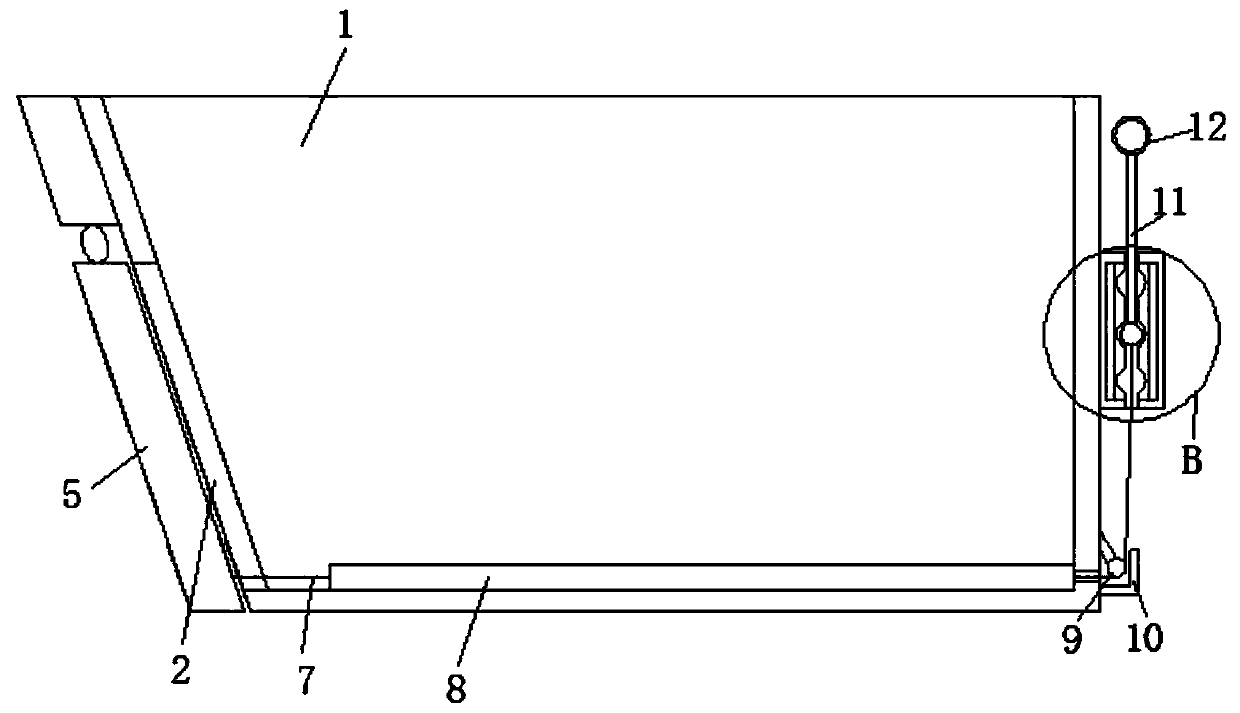

[0038] Such as Figure 1-2 As shown, a convenient dumping attapulgite soil transportation device includes a car basket 1 and a discharge hole 2, the discharge hole 2 is set on the front end of the car basket 1, and a sealing blocking plate 5 is arranged outside the discharging hole 2, and the sealing plug The upper end of the plate 5 is hinged on the connection block 3 through the hinge rod 4, the connection block 3 is fixedly arranged on the vehicle basket 1, and the sealing block 5 and the vehicle basket 1 are connected through the connection assembly 6;

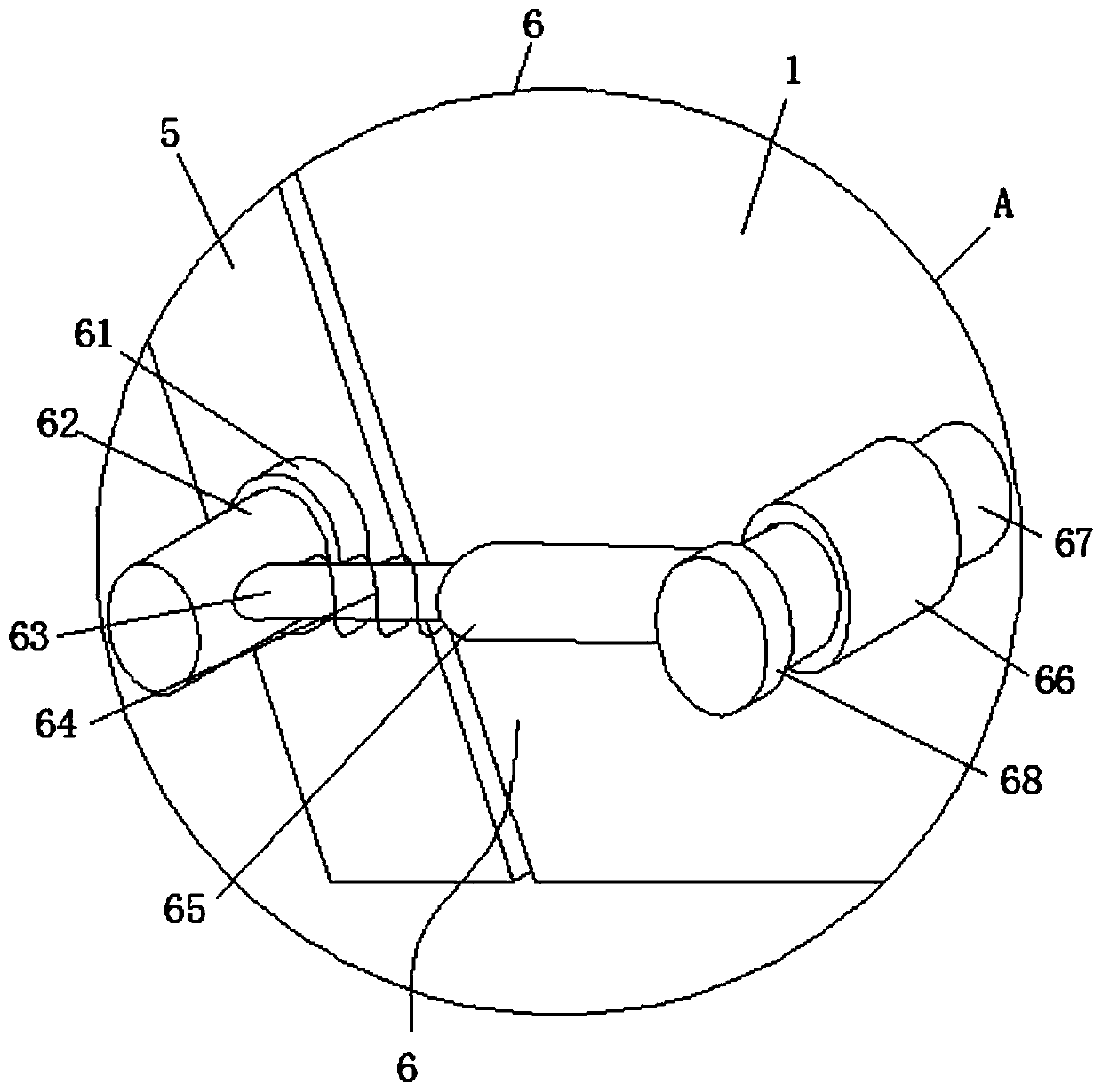

[0039] The connecting assembly 6 includes a rotating shaft 61 and a connecting rod 67. The rotating shaft 61 is fixed on the side wall of the sealing blocking plate 5. The rotating shaft 61 is provided with a first rotating rod 62, and the side wall of the first rotating rod 62 is provided with a guide Rod 63...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com