Aircraft surface defect scale controlling method capable of reducing influence on flow transition

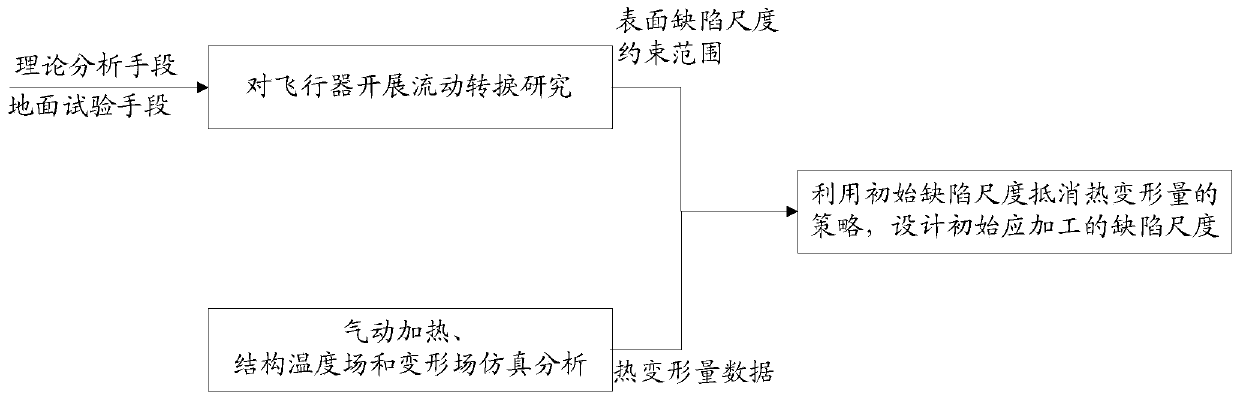

A control method and aircraft technology, applied to aircraft, instruments, motor vehicles, etc., can solve the problems of increasing the possibility of reliable work of the thermal protection system, the defect scale does not meet the constraint range, and the scale is difficult to be reasonably controlled, etc., to achieve Reduce the actual defect size, maintain the integrity of the shape, and avoid the effect of abnormal increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

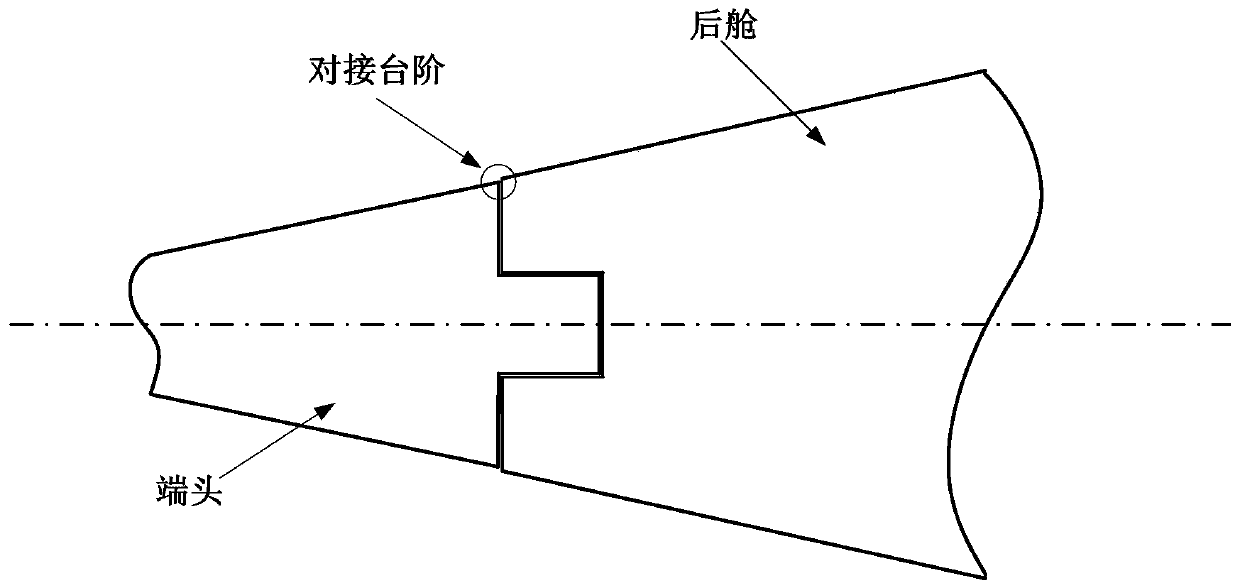

[0044] The specific implementation of the present invention is described by taking the control of the height of the docking step between two cabin sections of an aircraft as an example. Such as figure 2 As shown in , a docking step is formed between the two compartments of the terminal and the rear cabin.

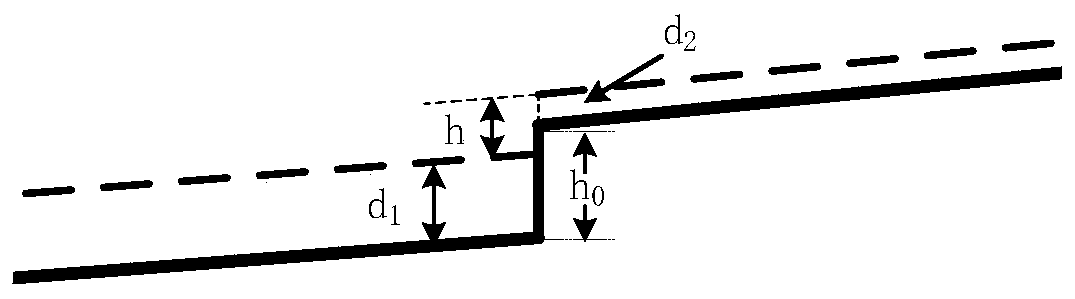

[0045] Such as image 3 As shown, the height of the defined step should be processed as h 0, the actual step height during the flight of the aircraft is h; due to the difference in the structure of the terminal and the rear cabin, the terminal is solid, and the materials of the two are also different. The difference in the thermal response of the two during the flight will lead to The amount of deformation is also different. The difference in the amount of thermal deformation of the two cabins will produce an additional step. The height of the extra step is defined as h', and the height of the step when the rear cabin shell is higher than the end is defined as a positive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com