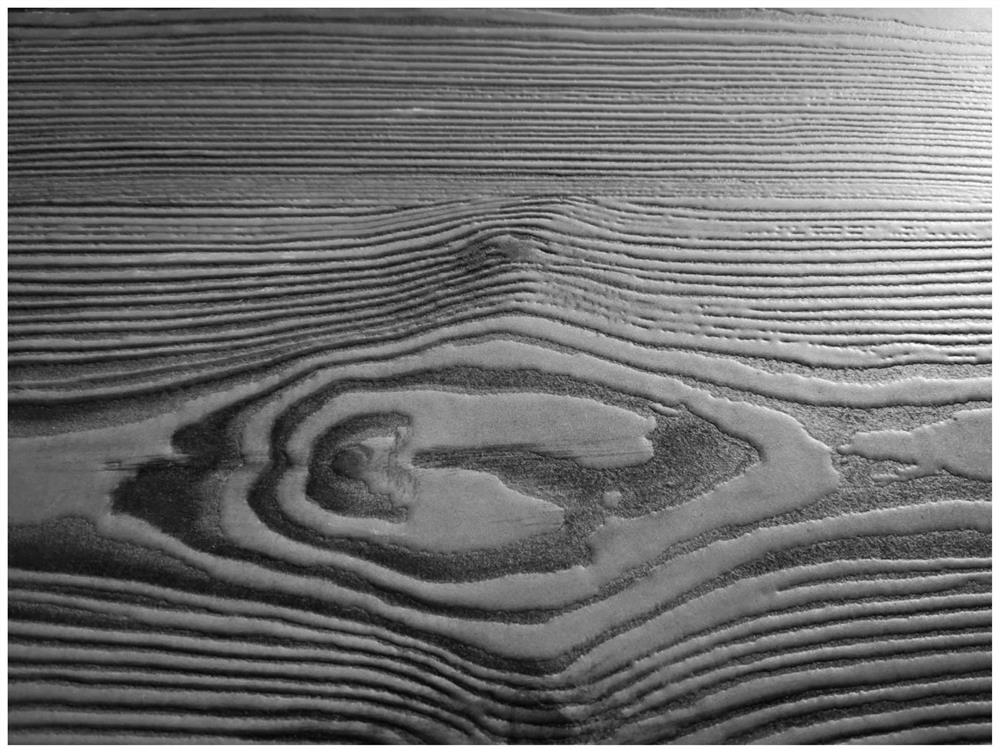

A ceramic tile with adjustable three-dimensional effect and preparation method thereof

A technology of three-dimensionality and ceramic tiles, which is applied in the field of ceramic tiles, can solve problems such as uncontrollable effects, overlapping pattern effects, and insufficient three-dimensionality, and achieve the effect of adjustable three-dimensionality, strong three-dimensionality, and strong three-dimensionality of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A method for preparing ceramic tiles with adjustable three-dimensional effect, comprising the following steps:

[0060] Step 1, preparing a dry billet: pressing the billet and drying to obtain a dry billet;

[0061] Step 2, applying top glaze: applying top glaze to the dry blank obtained in step one to obtain a top glaze layer;

[0062] Step 3, print color ink: according to pattern design, print color ink on the glaze layer that step 2 obtains, obtain color ink layer;

[0063] Step 4, print moisturizing ink: according to pattern design, print moisturizing ink on the color ink layer that step 3 obtains, obtain moisturizing ink layer;

[0064] Step 5, printing glue ink: print glue ink on the moisturizing ink layer obtained in step 4, and the printed pattern is identical to the texture of the moisturizing ink pattern and completely overlaps to obtain the glue ink layer;

[0065] Step 6, print deep ink: print deep ink in the area where the glue ink is not printed in step ...

Embodiment 2

[0099] A method for preparing ceramic tiles with adjustable three-dimensional effect, comprising the following steps:

[0100] Step 1, preparing a dry billet: pressing the billet and drying to obtain a dry billet;

[0101] Step 2, apply surface glaze: adopt glaze spraying cabinet to carry out surface glaze to the dry base that step 1 makes, obtain surface glaze layer; In the present embodiment, the specific gravity of surface glaze is 1.52g / cm 3 , the amount of glaze applied to the surface glaze is 350g / m 2 ;

[0102] Step 3, print color ink: according to pattern design, print color ink on the glaze layer that step 2 obtains, obtain color ink layer;

[0103] Step 4, print moisturizing ink: according to pattern design, print moisturizing ink on the color ink layer that step 3 obtains, obtain moisturizing ink layer; In the present embodiment, the inkjet amount of moisturizing ink is 25g / m 2 ;

[0104] Step 5, print glue ink: print glue ink on the moisturizing ink layer that ...

Embodiment 3

[0129] A method for preparing ceramic tiles with adjustable three-dimensional effect, comprising the following steps:

[0130] Step 1, preparing a dry billet: pressing the billet and drying to obtain a dry billet;

[0131] Step 2, apply surface glaze: adopt glaze spraying cabinet to carry out surface glaze to the dry base that step 1 makes, obtain surface glaze layer; In the present embodiment, the specific gravity of surface glaze is 1.5g / cm 3 , the amount of glaze applied to the surface glaze is 300g / m 2 ;

[0132] Step 3, print color ink: according to pattern design, print color ink on the glaze layer that step 2 obtains, obtain color ink layer;

[0133] Step 4, print moisturizing ink: according to pattern design, print moisturizing ink on the color ink layer that step 3 obtains, obtain moisturizing ink layer; In the present embodiment, the inkjet amount of moisturizing ink is 10g / m 2 ;

[0134] Step 5, print glue ink: print glue ink on the moisturizing ink layer that s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com