Assembly type building structure system and stand column and cross beam connecting device thereof

A technology of building columns and connecting devices, which is applied in the direction of building construction and construction, can solve the problems of complex installation methods, reduce the strength of components, and take a long time, so as to achieve the effect of facilitating repeated use, reducing production costs, and fast installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

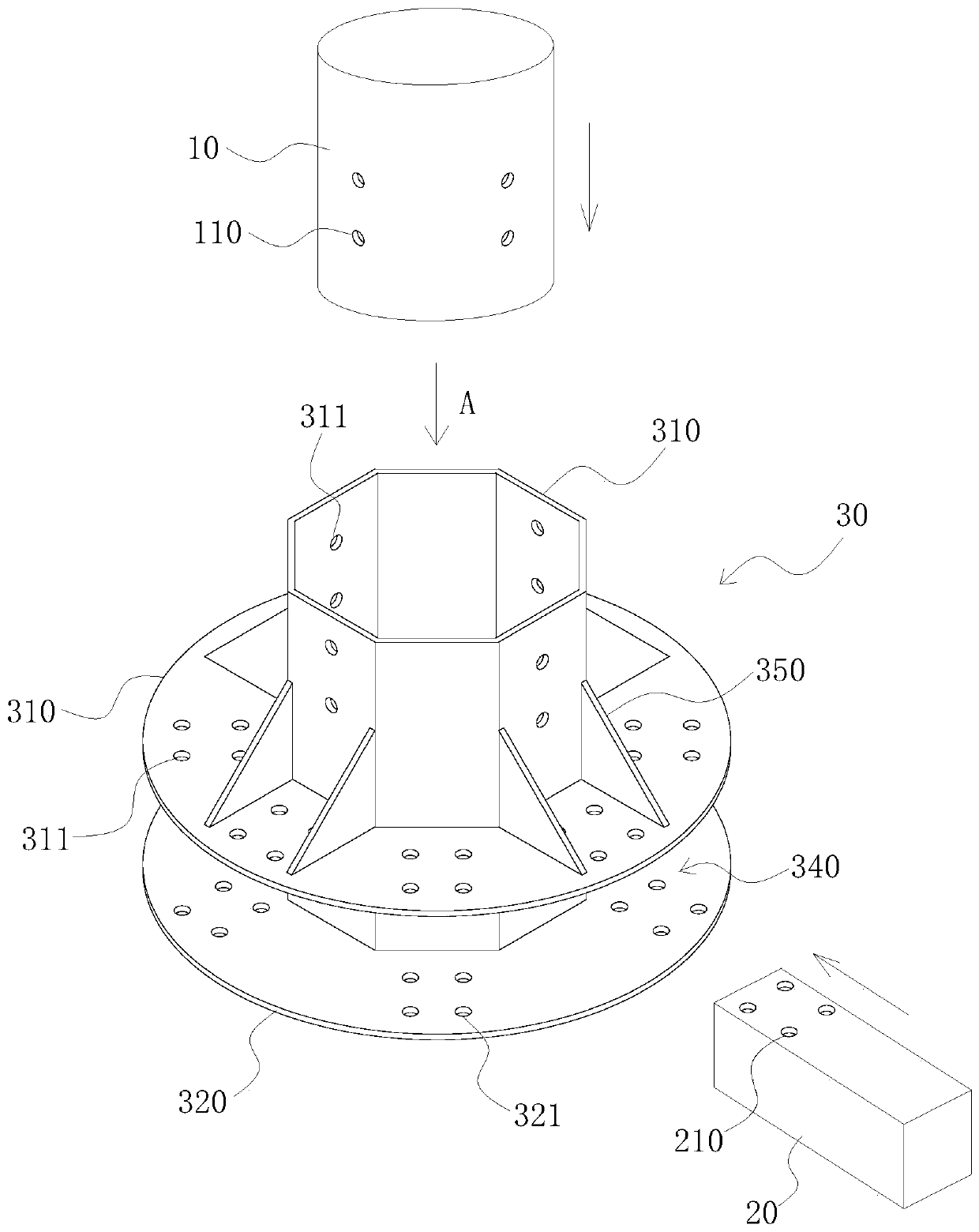

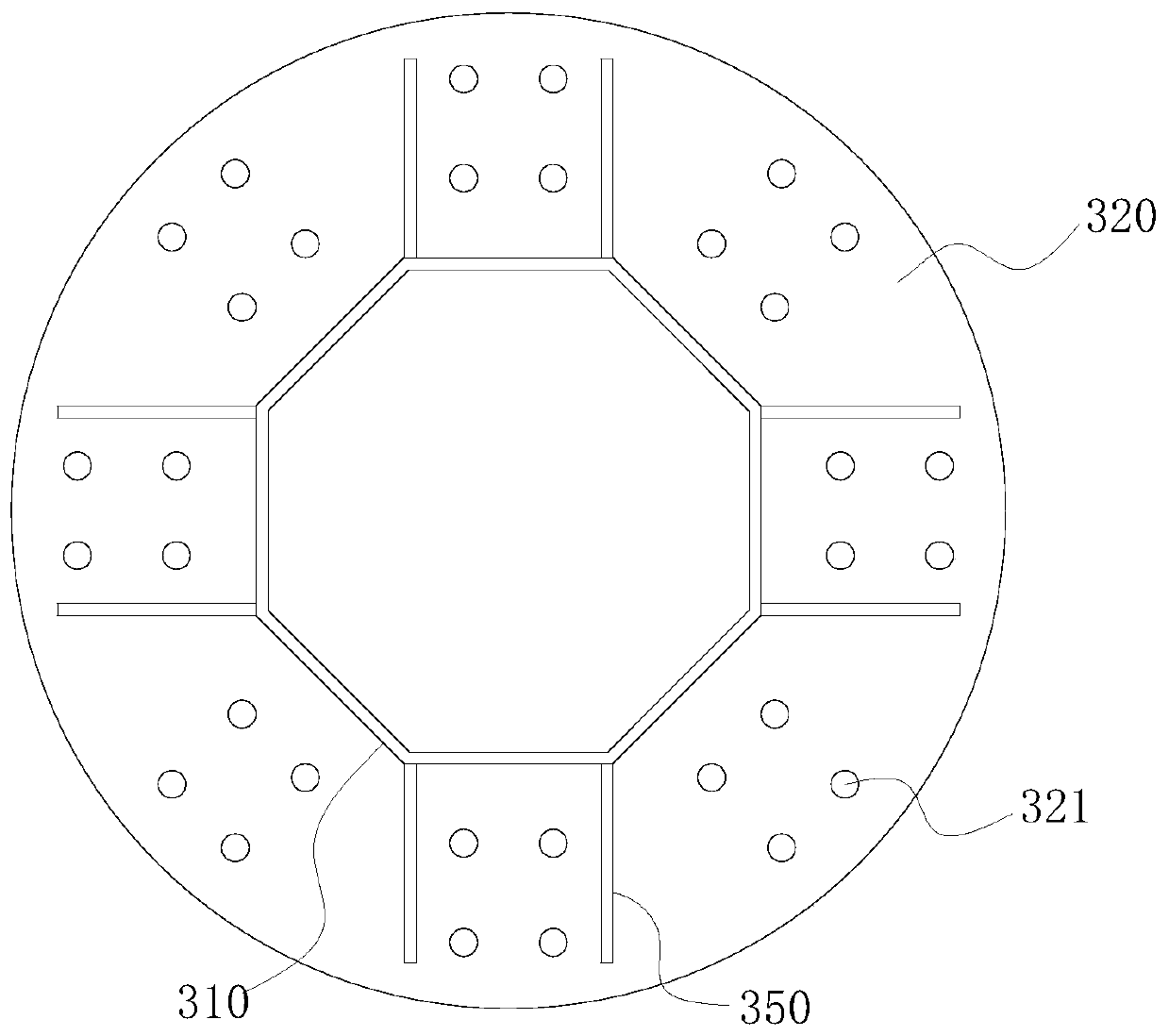

[0024] Such as figure 1 As shown, a prefabricated building structure system includes a column 10, a plurality of beams 20 and a connecting device 30 between the column and the beam. The first connection plate 320 and the second connection plate 330 are sleeved on the fixing sleeve 310 and set opposite to each other. The cooperation between the first connection plate 320 and the second connection plate 330 forms a plurality of installation positions arranged around the circumference of the fixing sleeve 310 340 , the installation position 340 corresponds to the beam 20 one by one, and the beam 20 is inserted into the installation position 340 and is detachably connected with the first connection plate 320 and the second connection plate 330 .

[0025] During installation, the column 10 is inserted into the fixing sleeve 310 for fixing, and then the beam 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com