Variable valve mechanism

A valve mechanism and variable technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve problems such as poor intake oil and gas mixing, poor engine economy and emissions, and large intake negative power, etc., to achieve improvement Intake and exhaust conditions, low manufacturing difficulty, and the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

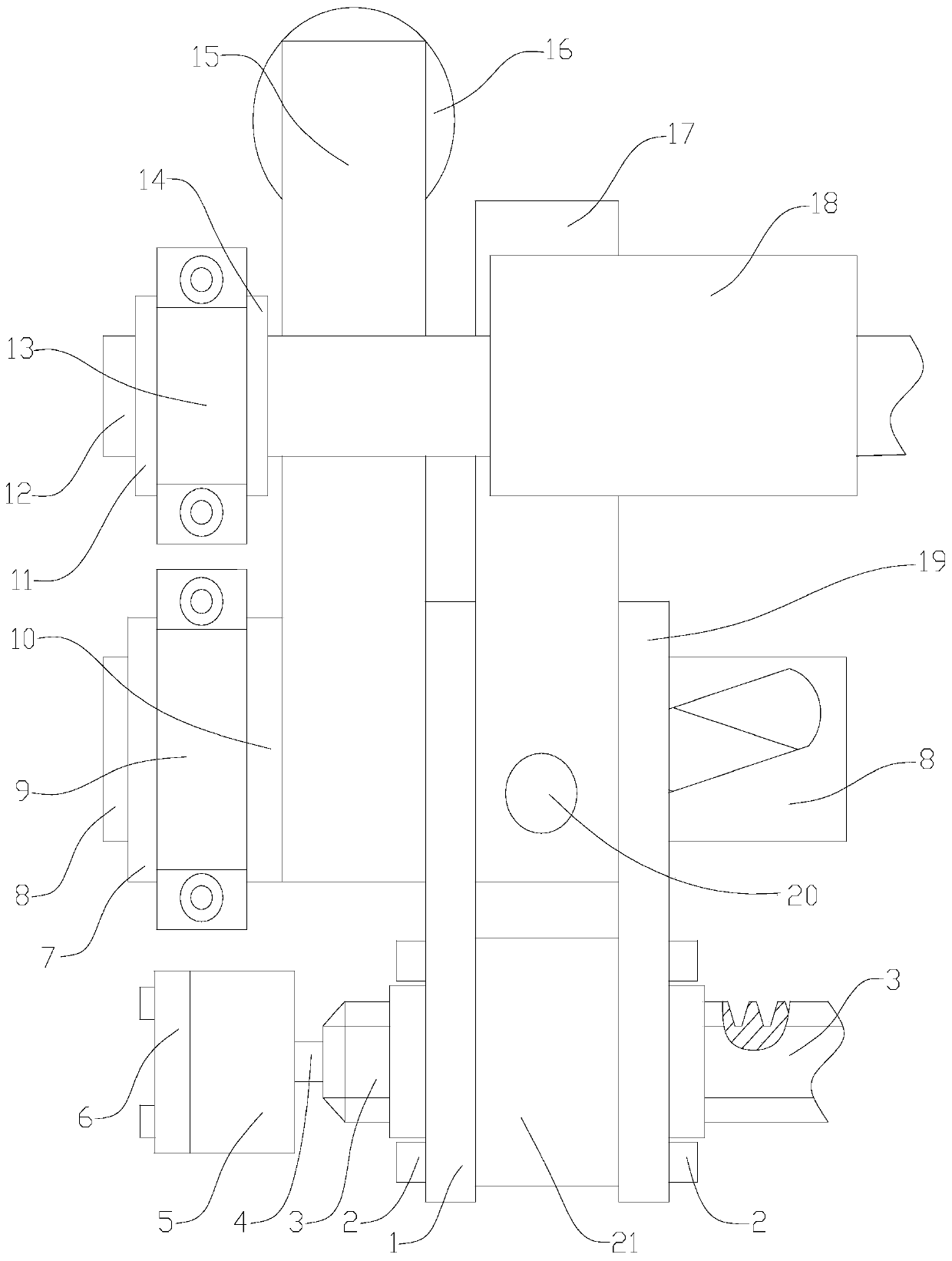

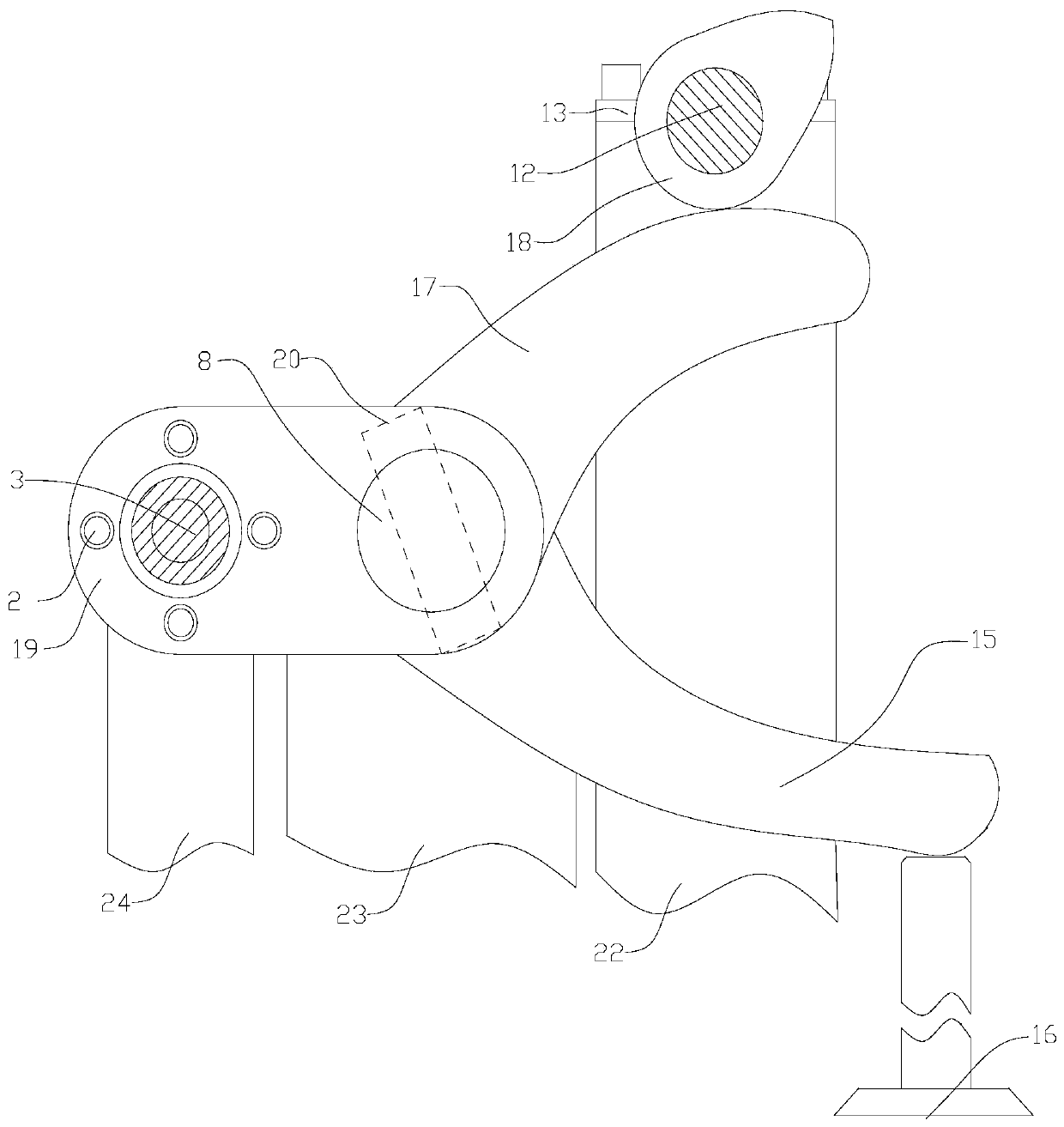

[0022] Referring to the accompanying drawings, the embodiments of the present invention are described, in conjunction with the attached Figure 1-11 Embodiments of the present invention are described in detail.

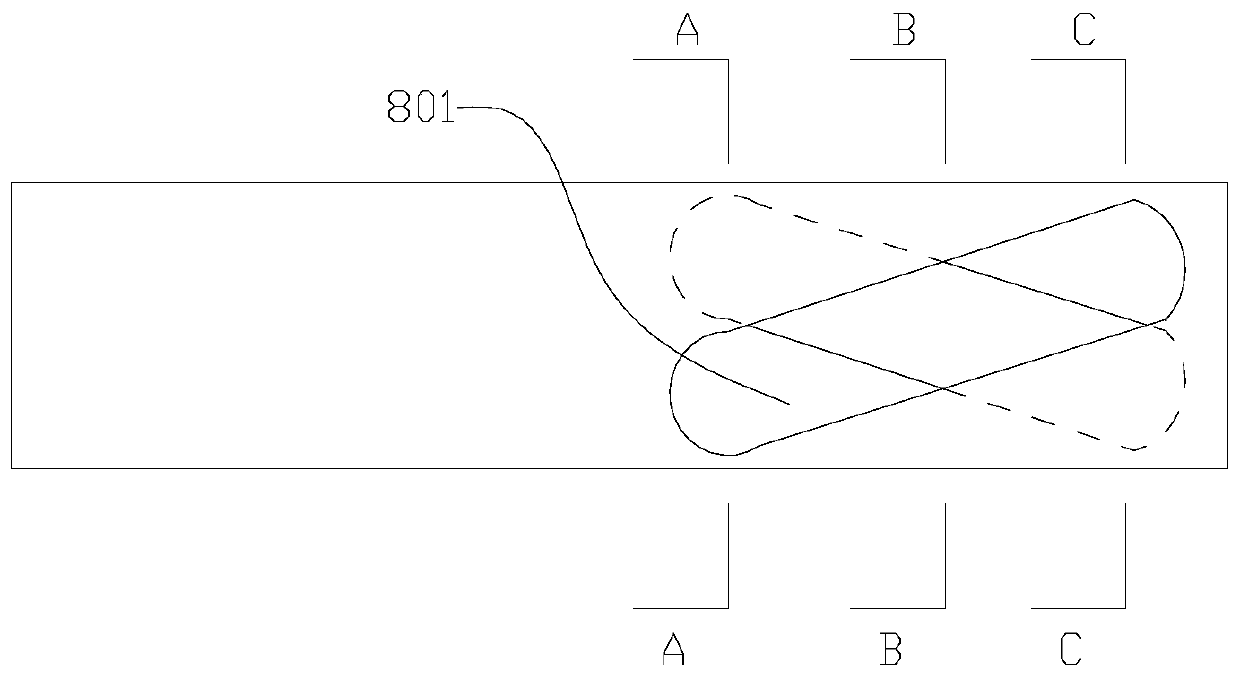

[0023] The main parts that the present invention comprises are: camshaft (12), rocking arm a (15) and rocking arm b (17), rocking arm shaft (8) and valve (16), pin (20) and chute (801) , displacement sleeve (21), motor (5) and related motor shaft (4) and threaded rod (3). The motor shaft drives the threaded rod to move axially through the motor control, and then drives the displacement sleeve to move on the rocker arm, changing the swing law of the rocker arm b (17), and then changing the lift of the valve.

[0024] The camshaft (12) of the present invention is placed between the cover plate b (13) and the support b (22), and is fitted with clearance; the cover plate b (13) and the support b (22) are placed on the limit boss Between c (22) and the limit boss d (14),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com