Positioning device and a method for producing the positioning device

A technology for positioning equipment and housings, applied in mechanical equipment, manufacturing tools, welding equipment, etc., can solve problems such as inadvisability, increased manufacturing costs, and increased manufacturing costs of positioning equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

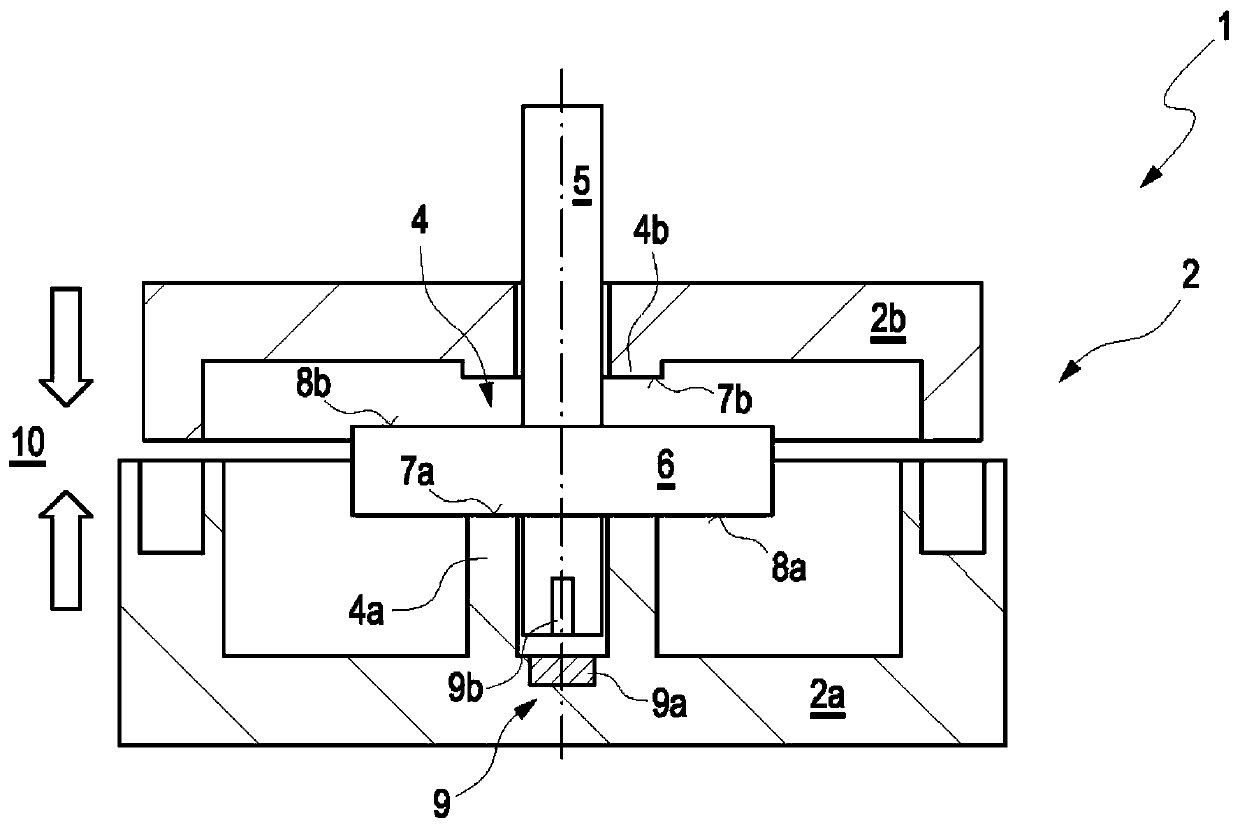

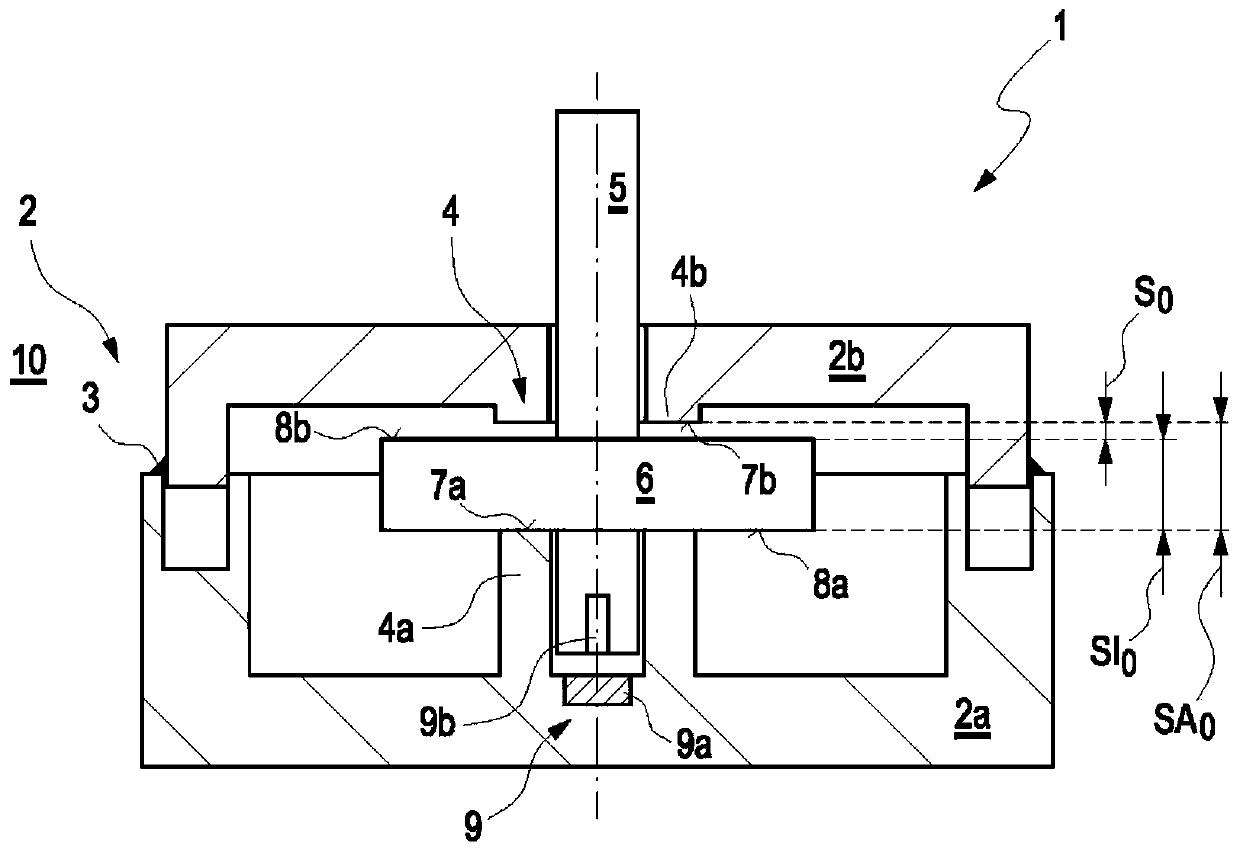

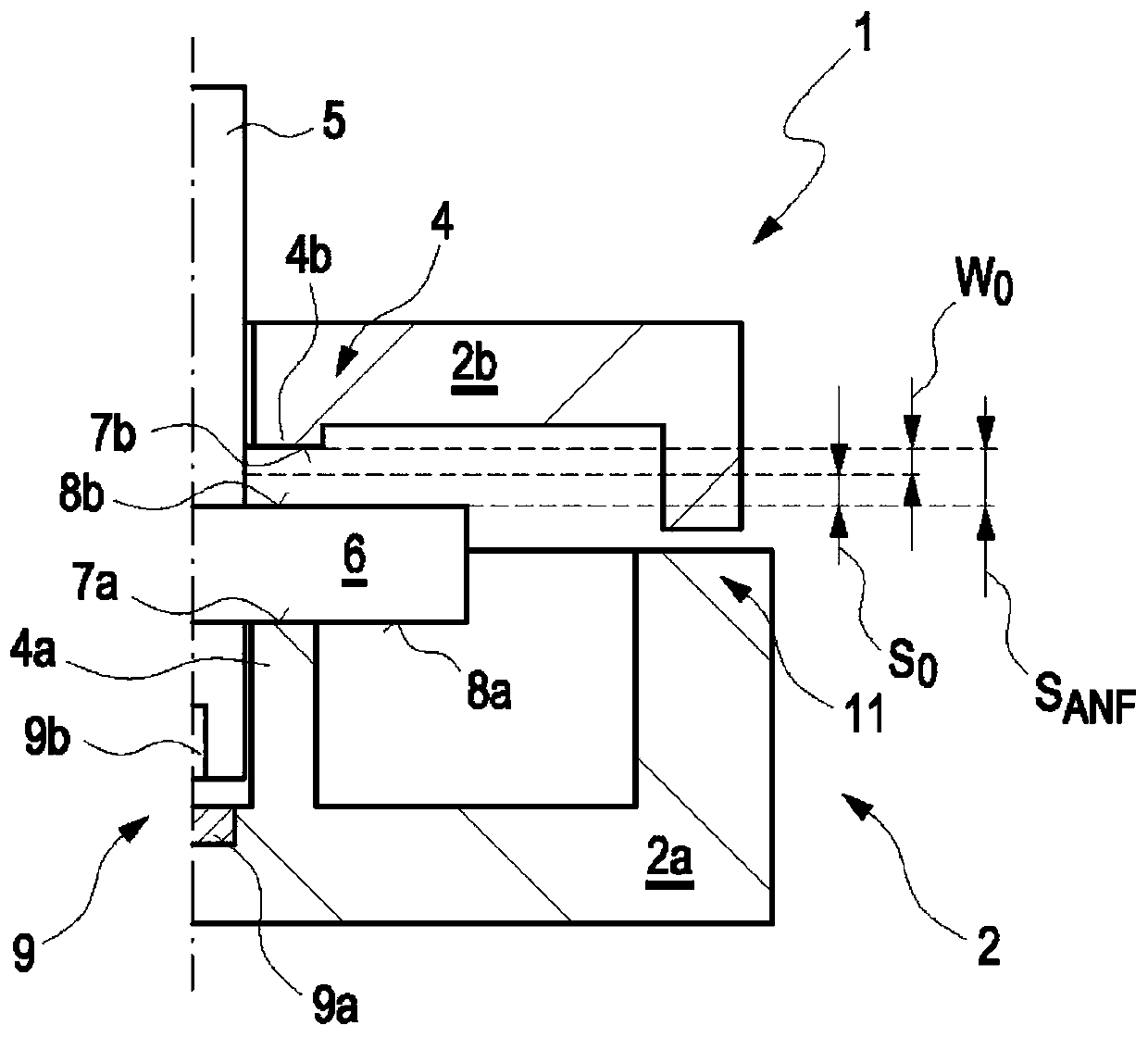

[0027] figure 1 and figure 2 It shows that the positioning device 1 according to the present invention is adjusting the predetermined axial clearance S 0 (Such as figure 2 shown in ) before and after cross-sectional view. The positioning device 1 comprises a housing 2 having a first housing part 2a and a second housing part 2b, in figure 2 The first housing part 2 a and the second housing part 2 b have been welded together via a welded connection 3 . Here, the first housing part 2a comprises a first integrally formed support 4a, the second housing part 2b comprises a second integrally formed support 4b, the first integrally formed support 4a and the second integrally formed support The parts 4b together form the bearing device 4 within the housing 2 . In the housing 2, an output shaft 5 and an output wheel 6 of a transmission (not shown here) are arranged. An output wheel 6 is non-rotatably connected to the output shaft 5 so that by driving the output wheel 6 the outp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap