Height detector for explosive column in detonator

A technology of height detection and powder column, which is applied in the direction of measuring devices, instruments, and electrical devices, can solve problems such as low detection efficiency, inaccurate detection, and potential safety hazards, so as to improve detection efficiency, improve detection accuracy, and reduce possible sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

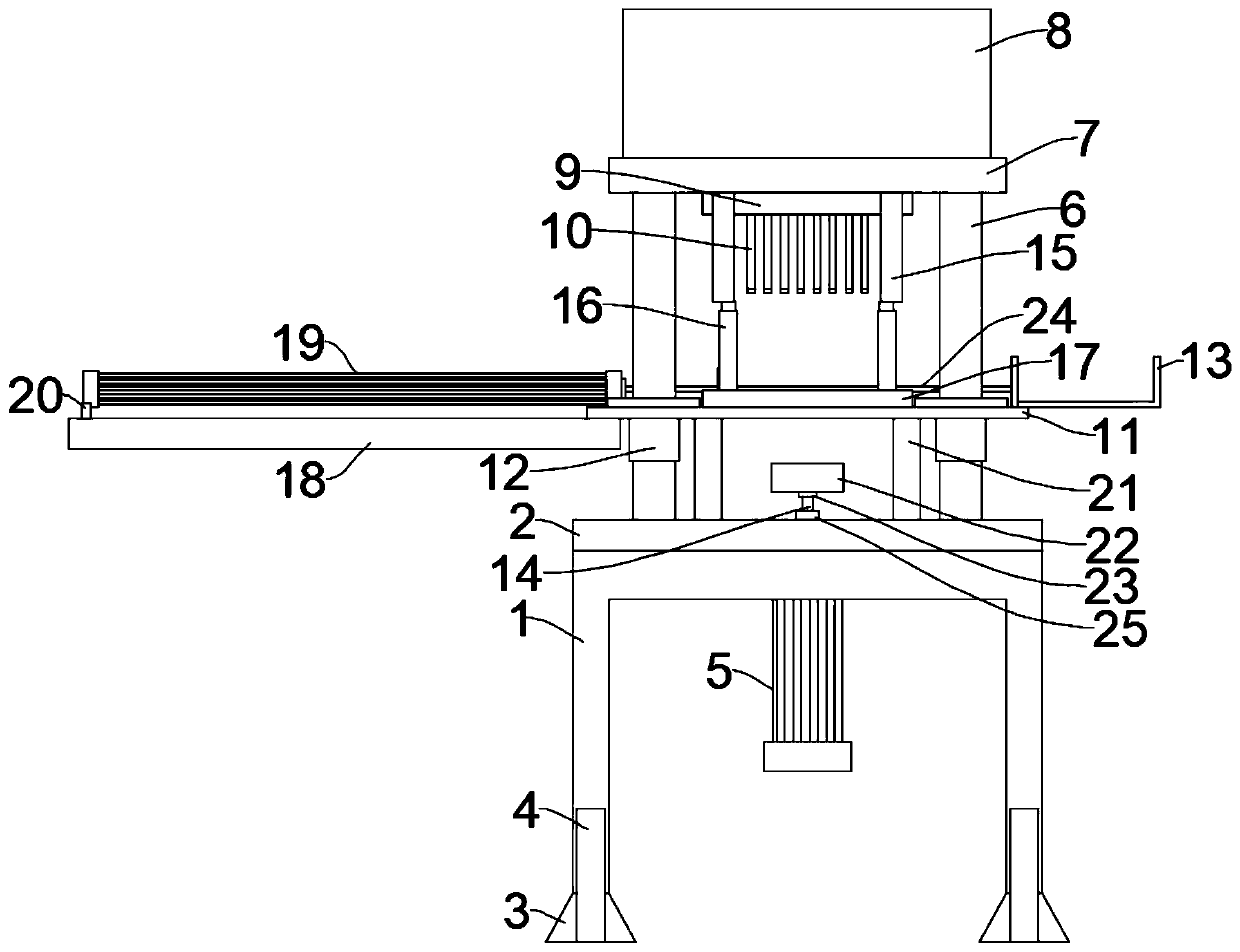

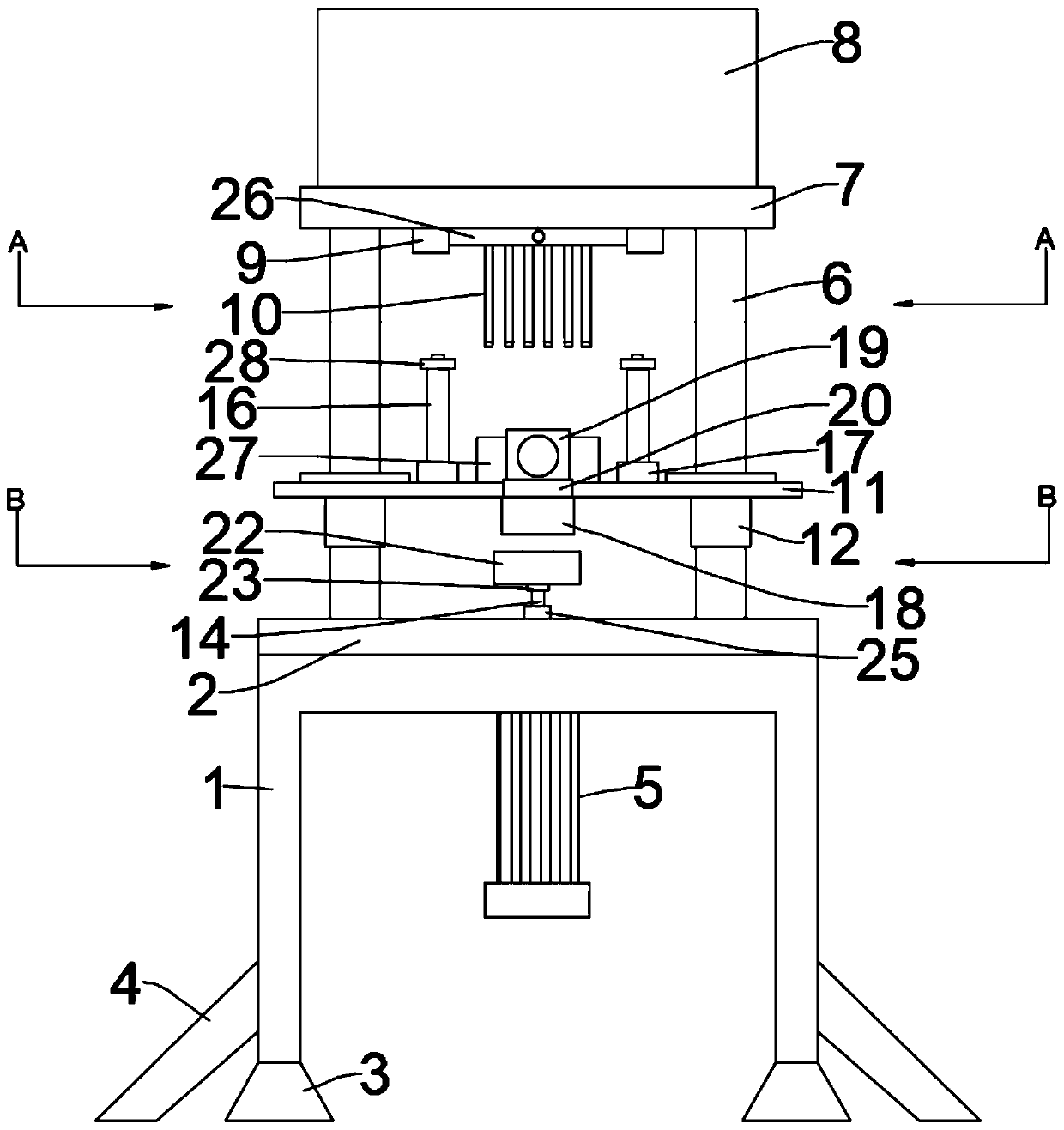

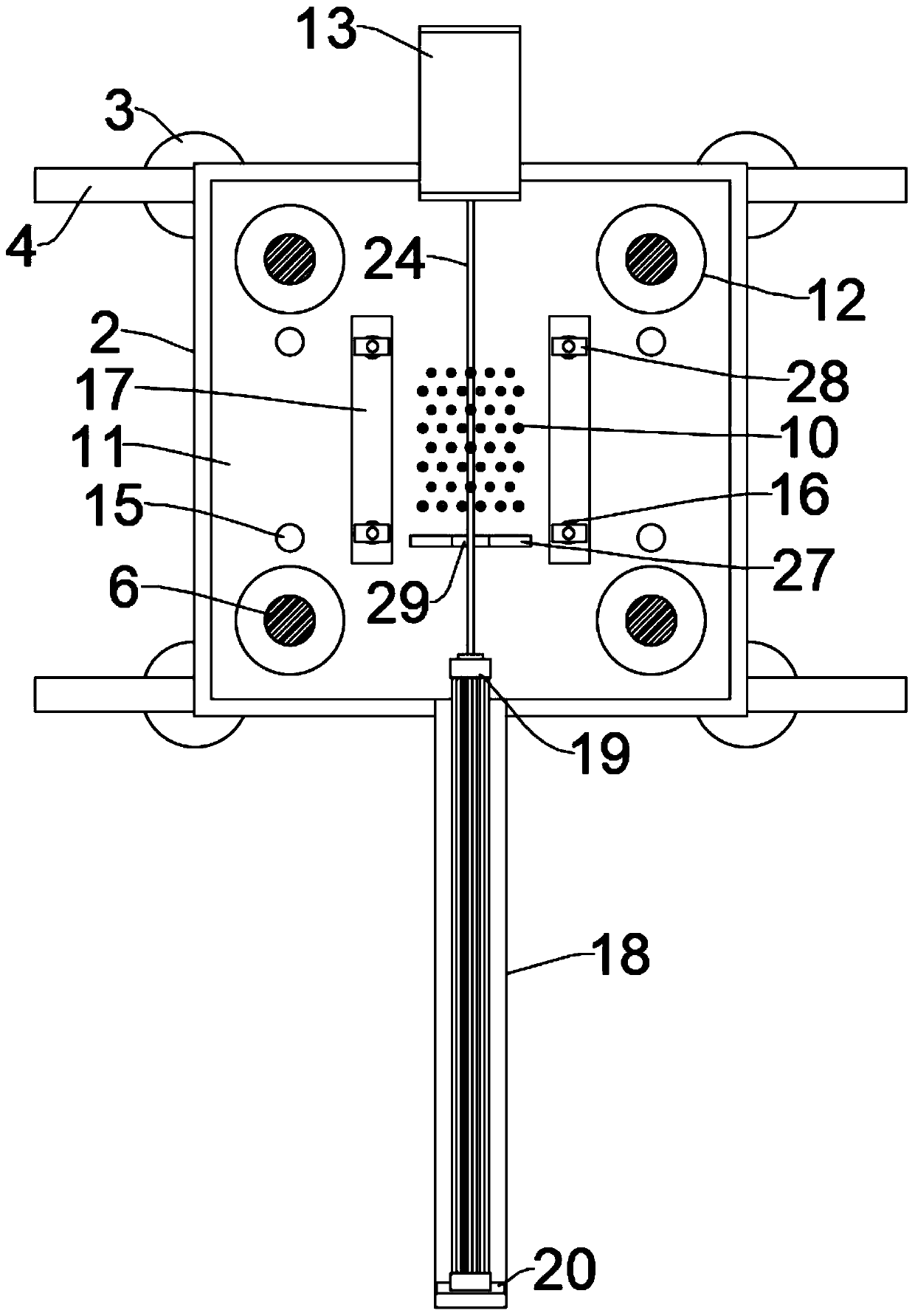

[0036] like Figure 1-Figure 4 As shown, the present embodiment provides a detonator internal charge height detection machine, including a carrier platform 2, a movable plate 11 arranged horizontally, a fixed platform 7, a first driving device and a second driving device for driving the mold 30 to move.

[0037]The top of the bearing platform 2 is fixedly provided with 4 vertical support rods 6, wherein the bearing platform 2 is square, and the 4 support rods 6 are located at the four corners of the bearing platform 2, and the movable plate 11 is positioned at the vertical top of the bearing platform 2, The movable plates 11 are slidably connected to the four supporting rods 6 , wherein the movable plates 11 are also square, and the upper ends of the supporting rods 6 slide through the four corners of the movable plates 11 . The fixed platform 7 is positioned at the vertical top of the movable plate 11, wherein the fixed platform 7 is also square, and the bottom four corners o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com