High-temperature large-load test fixture and test method for turbine blade joggle joint structure

A technology of turbine blades and test fixtures, which is applied in the testing of machine/structural components, testing of mechanical components, and testing the strength of materials by applying repetitive force/pulsation force, etc. It can solve the problems of unbalanced force, slippage, and easy compression of blades Collapse and other problems to achieve the effect of reducing raw material costs

Active Publication Date: 2019-12-31

BEIHANG UNIV

View PDF13 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The technical problem to be solved by the present invention is to overcome the deficiencies of the prior art, provide a high-temperature and large-load test fixture and test method for the tenon joint structure of the turbine blade, and overcome the high temperature of 500°C and the pressure of 150 kN applied to the tenon joint structure of the turb

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

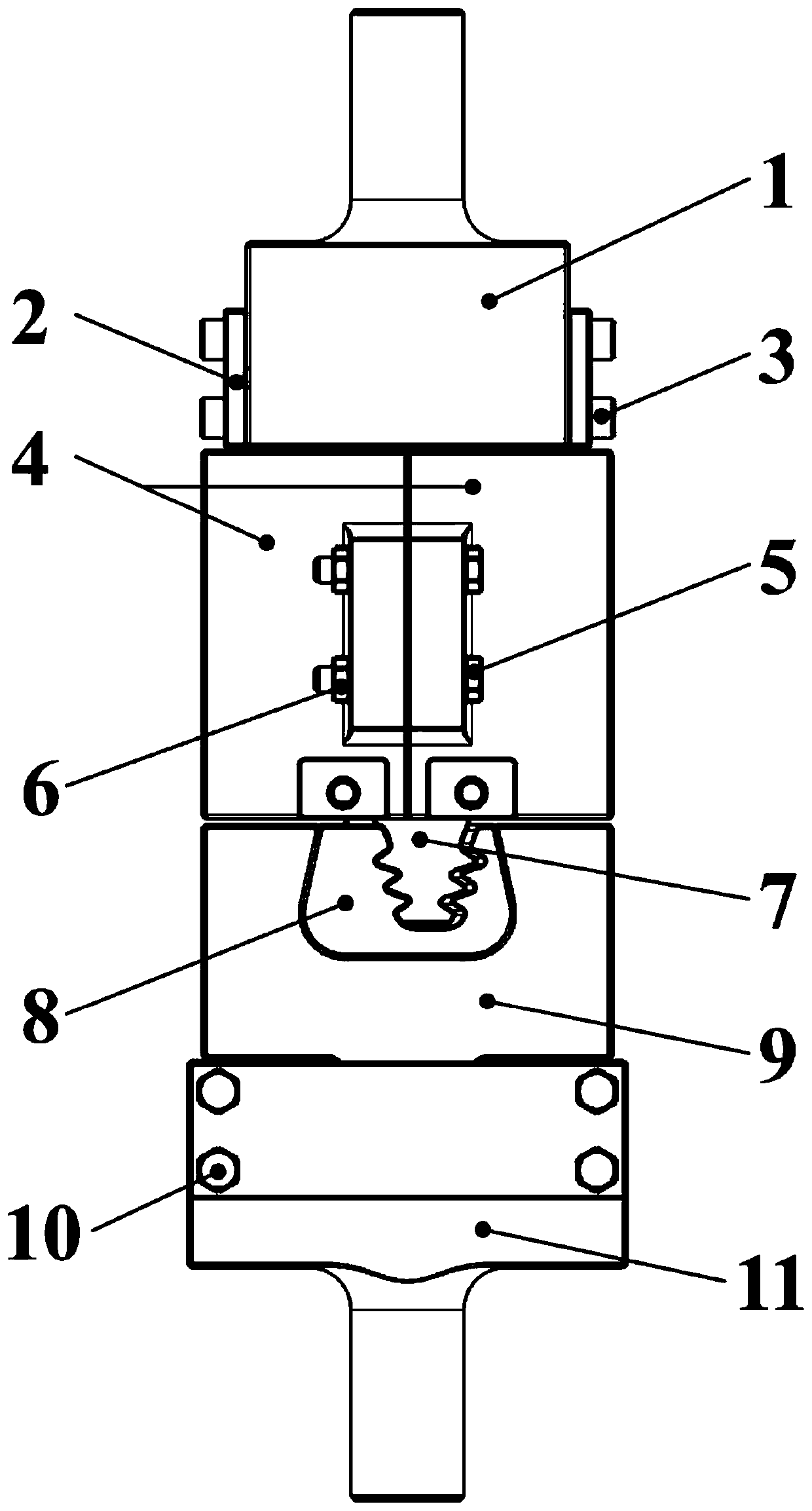

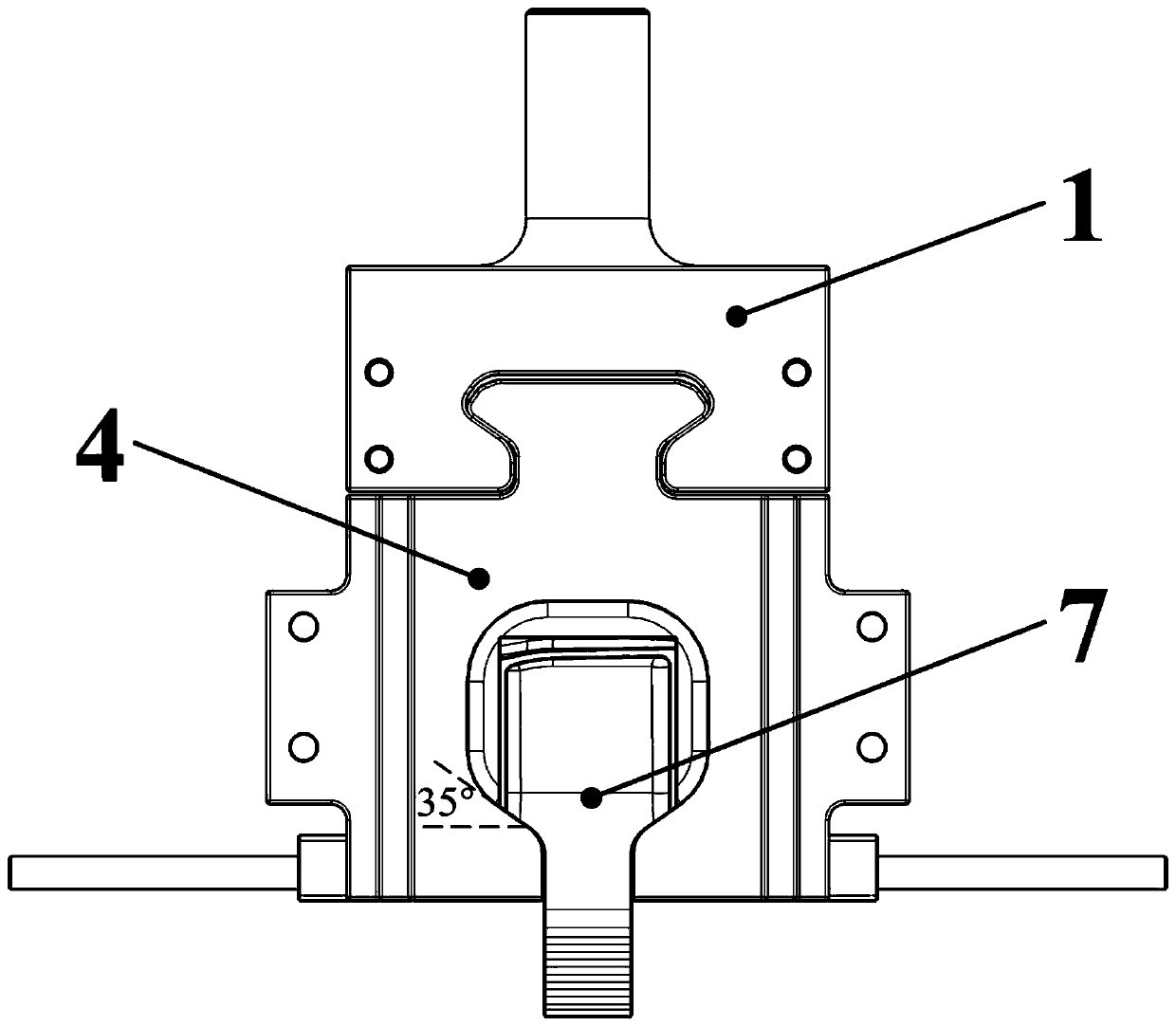

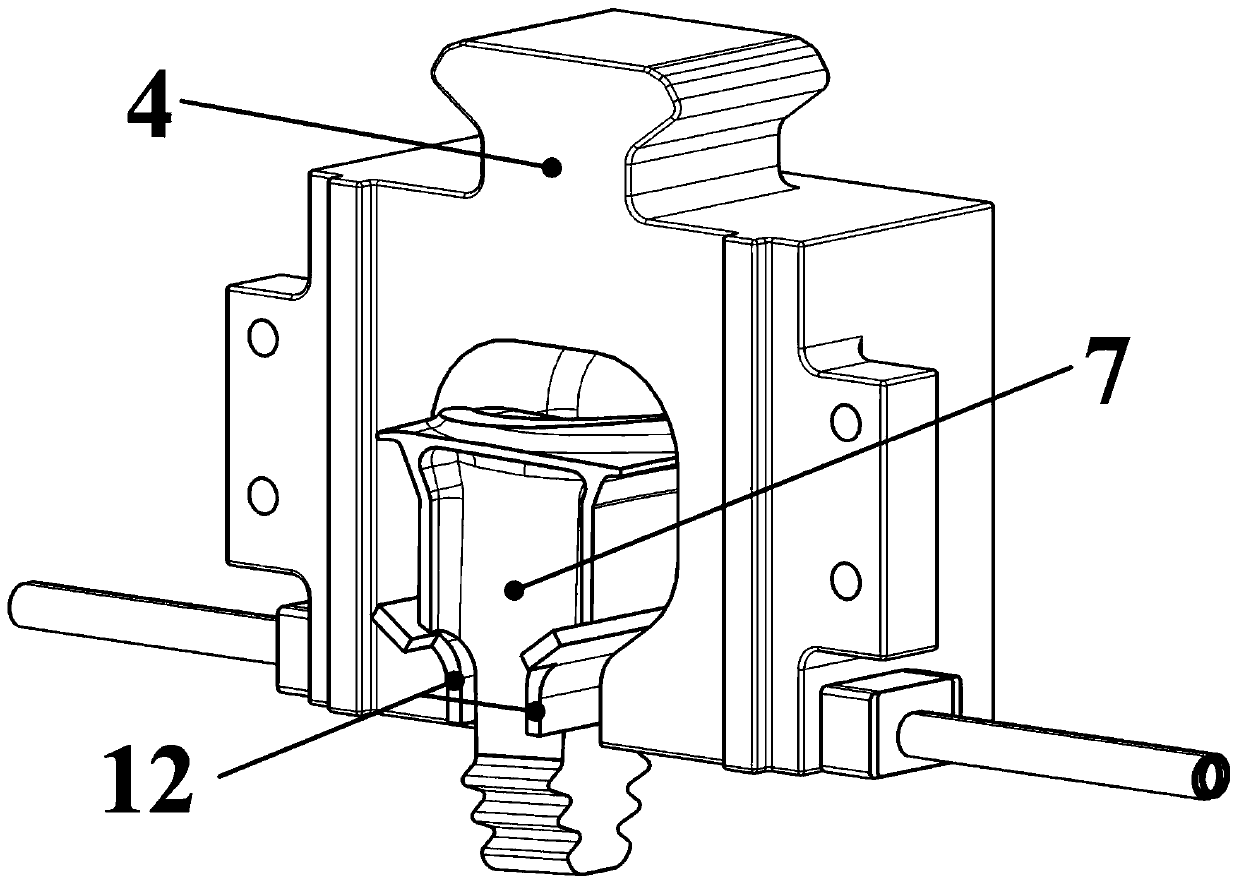

The invention relates to a high-temperature large-load test fixture and test method for a turbine blade joggle joint structure, which can be used for test loading of thermal mechanical fatigue, creep-fatigue, low-cycle fatigue, creep and the like of the turbine blade joggle joint structure. The upper end and the lower end of the fixture are respectively connected with a fatigue testing machine through a clamping component, and the clamping components are connected with a turbine blade upper fixture and a turbine blade lower fixture through dovetail-shaped joggle joint structures; the turbine blade upper fixture is mainly composed of two components, a cold water channel is formed in the turbine blade upper fixture, a turbine blade is installed in an inner cavity formed by the two components, and the installation and positioning of the turbine blade and the blade upper fixture and the transmission of an axial load are achieved through a pair of inclined planes of the root extending section; the lower fixture is made of a high-temperature alloy material and is matched with a turbine blade tenon through a longitudinal tree-shaped mortise, and the blade joggle joint structure can be heated by using an induction heating coil. According to the invention, stable clamping of the turbine blade is realized, and the test requirements of applying a temperature load ranging from room temperature to 500 DEG C and a mechanical load from 0N to 150kN to the joggle joint structure can be met.

Description

Technical field [0001] The invention belongs to the field of turbine blade tenon joint structure testing, and particularly relates to a high temperature and large load test fixture and test method for a turbine blade tenon joint structure, which can perform high temperature and large load fatigue on the turbine blade tenon joint structure under laboratory conditions Load environment simulation, based on this, can perform composite fatigue tests such as turbine blade thermomechanical fatigue, test the life of the turbine blade tenon structure, and provide guarantee for the safe and reliable operation of the gas turbine engine. It belongs to the field of gas turbine engine technology. Background technique [0002] The turbine blades of a gas turbine engine work in extreme environments of high temperature, high pressure, and high speed. Under such a complex load environment, the mortise joint structure is prone to fatigue failure. Turbine blades are one of the core components of gas...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/32G01N3/04G01M13/00

CPCG01M13/00G01N3/04G01N3/32G01N2203/0073G01N2203/0226G01N2203/0423

Inventor 胡殿印王荣桥郝鑫奕张斌鄢林曹福粱毛建兴

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com