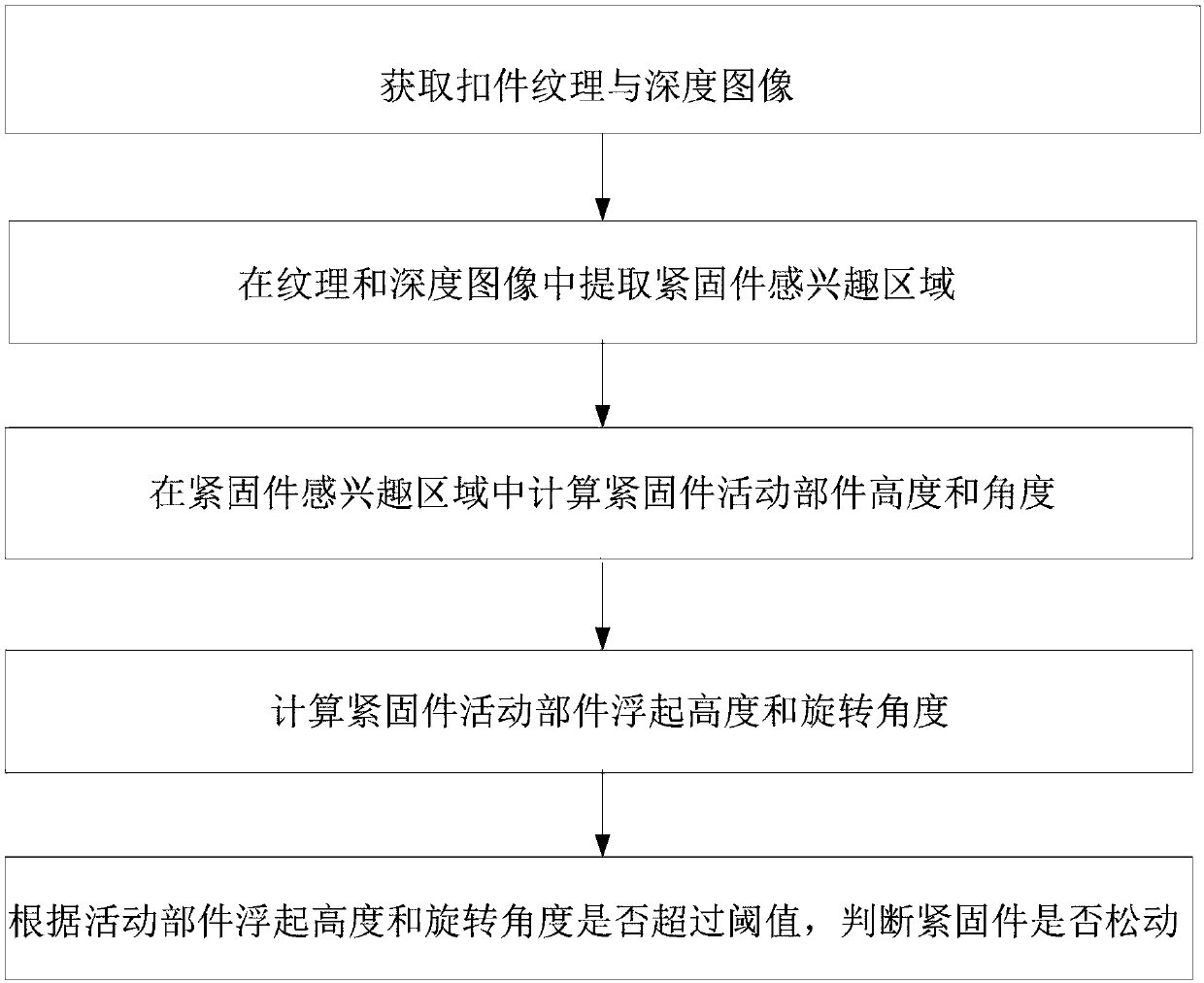

Track fastener fastener looseness detection method based on texture and depth images

A technology of depth image and texture image, which is applied in the field of railway infrastructure detection, can solve problems such as low efficiency, poor precision, and limited scope of application, and achieve the effects of reducing accuracy requirements, convenient use, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] by Figure 5 The W-shaped fastener shown is taken as an example. The fastener of this type of fastener is composed of a nut 7 and a screw rod 6. The nut 7 is a movable part, and the screw rod 6 is a fixed part.

[0042] Step 1: Use the texture and depth hybrid imaging system to obtain the surface texture image and depth image of the rail fastener fastener;

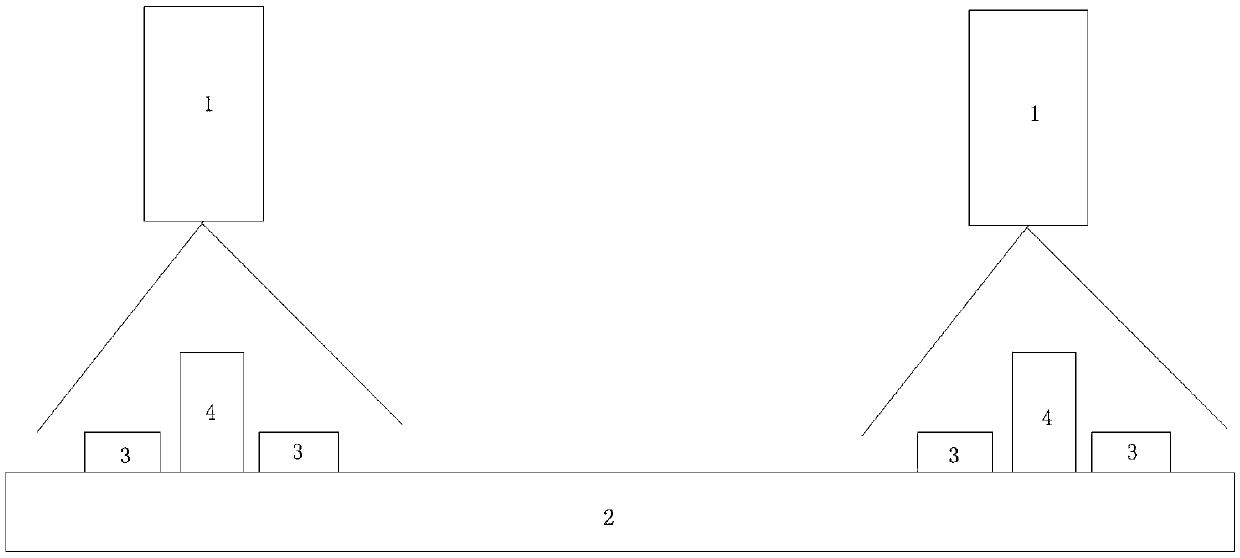

[0043] Such as figure 2 As shown in Fig. 1, the texture and depth fusion imaging system 1 is used, perpendicular to the track plane, to capture texture images and depth images of the track and both sides.

[0044] The texture and depth fusion imaging system in this embodiment is composed of a line array scanning imaging and a line structured light three-dimensional scanning device. Correct the scanning direction for the acquired texture image and depth image, so as to ensure that the actual physical dimensions represented by the unit pixel of the horizontal and vertical coordinates in the texture image and the de...

Embodiment 2

[0060] The difference from Example 1 is that in step 3, the non-zero pixel value with the highest number of occurrences in the sequence S is taken as the height h of the active part c .

Embodiment 3

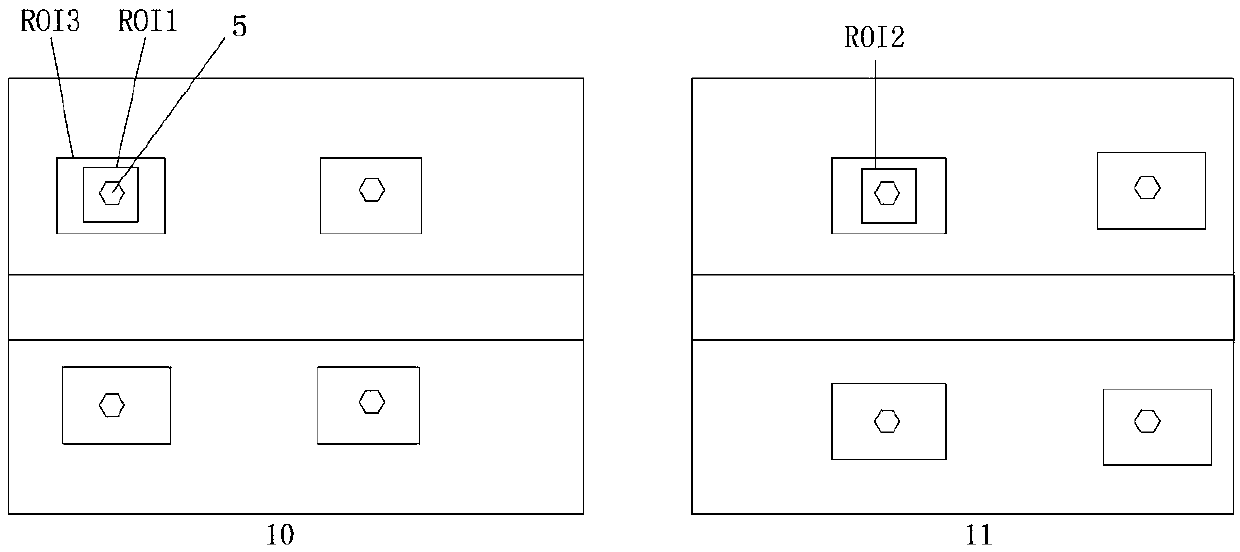

[0062] The difference from Example 1 is that the calculation of ROI1 and ROI2 in step 2 adopts the following method: on the depth image, according to the prior information of the height value of the fastener base or the sleeper, in the area where fasteners appear on both sides of the track, Carry out image threshold segmentation to detect fasteners; extract the fastener ROI2 in the depth image according to the position of the fastener in the fastener, and transform the position of ROI2 according to the positional relationship between the texture image and the depth image to obtain the tightness in the texture image. Firmware ROI1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com