Circle center sub-pixel precision positioning method

A positioning method and sub-pixel technology, applied in image analysis, image data processing, instruments, etc., can solve problems such as long running time, complex algorithm process, and large amount of calculation, so as to improve calculation efficiency and algorithm stability, and improve calculation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

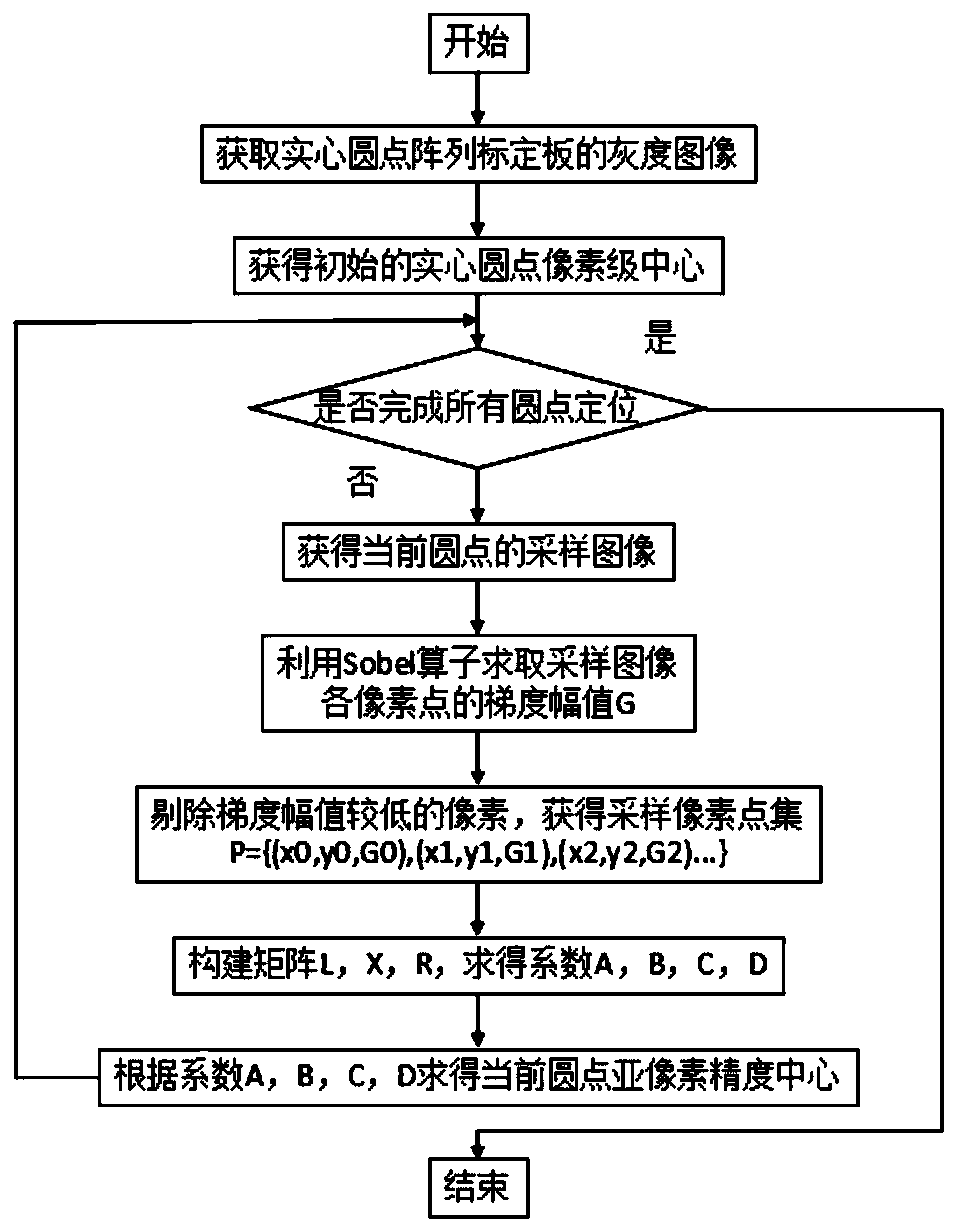

[0029] Such as figure 1 As shown, a sub-pixel precision positioning method for the center of a circle includes the following steps:

[0030] Step 1. Perform image binarization and Blob screening on the grayscale image to obtain the initial center coordinates of the dots in the image;

[0031] Step 2. Assuming the initial center coordinate C0 of one of the dots, set a sampling side length n, take C0 as the center to obtain an nxn sample image from the image, and ensure that the current dot is completely contained in the sampling image and does not contain other dots;

[0032] Step 3. For each pixel in the sampled image, use the Sobel operator in the X and Y directions to obtain the gradient Gx of the current pixel in the X direction and the gradient Gy in the Y direction, then the gray gradient amplitude of the current pixel The value G is:

[0033]

[0034] Step 4. Set a gradient amplitude threshold Gt. For each pixel in the sampled image, the pixel coordinates whose gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com