Method for determining an offset of a rotor position sensor, control device for a converter, and electric machine for a vehicle

A rotor position and control device technology, which is applied to devices using electric/magnetic methods, control generators, control electromechanical transmissions, etc., can solve problems such as offset, reduce component costs, and eliminate voltage measurement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

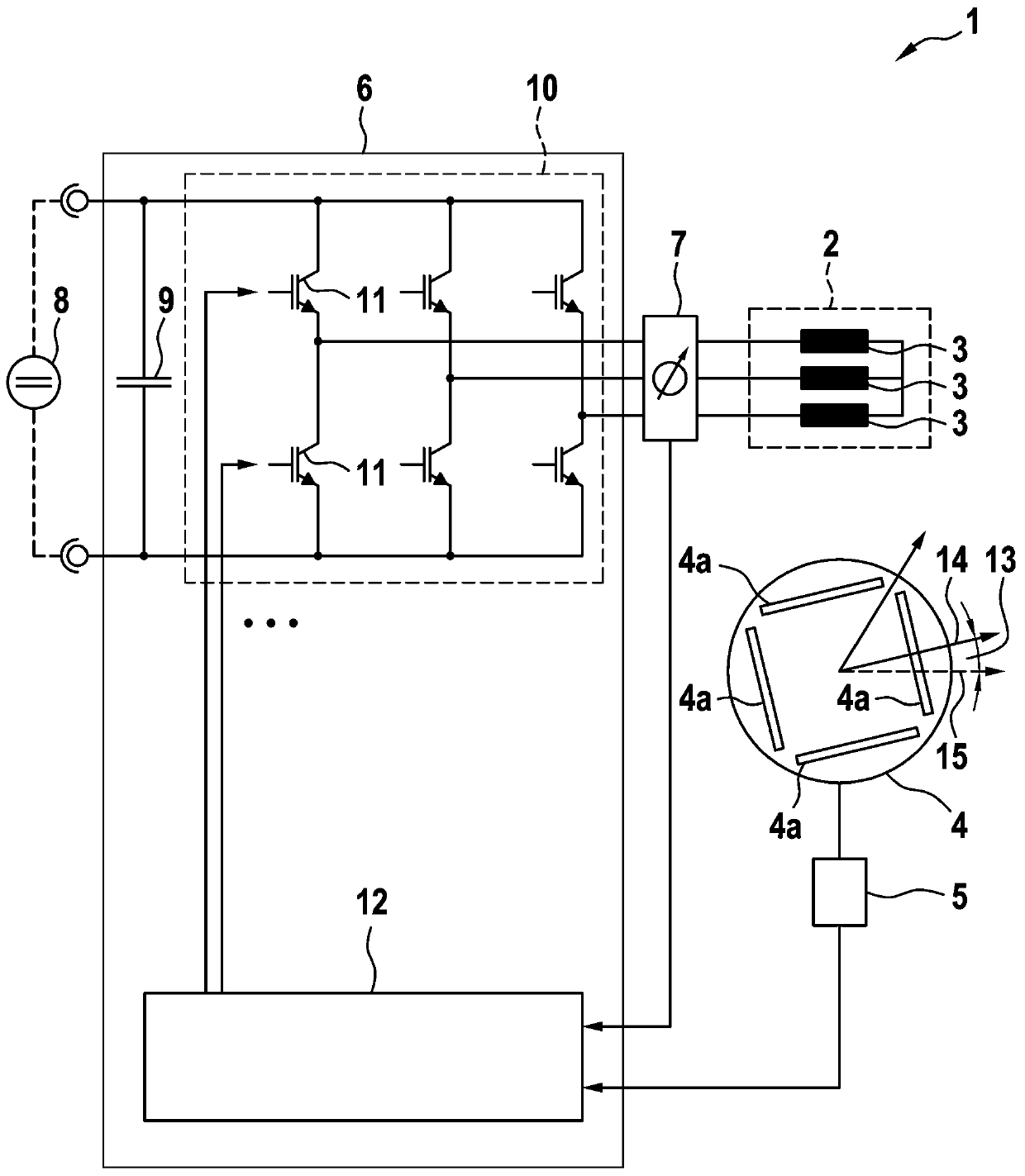

[0030] figure 1 is a schematic diagram of an embodiment of an electrical machine 1 comprising a stator 2 with a stator winding 3 , a rotor 4 , a rotor position sensor 5 arranged at the rotor and an inverter 6 arranged for the stator winding 3 Supply polyphase AC voltage. The rotor has a plurality of permanent magnets 4a or is externally excited. Furthermore, the electric machine 1 has a current measuring device 7 which detects the phase currents in the stator winding 3 . The electric machine 1 is used as the drive machine of an electric or hybrid vehicle with a high-voltage battery 8 , which supplies an inverter 6 on the input side.

[0031] On the input side, the converter 6 comprises an intermediate circuit capacitor 9 and a power unit 10 with a plurality of switching elements 11 connected to form half bridges, the respective half bridges supplying the phases of the stator 2 . Furthermore, the converter 6 has a control device 12 which actuates the switching element 11 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com