Stainless Steel Barrel Welding Machine

A stainless steel barrel and welding machine technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low manual welding efficiency, jittering solder joints, and affecting production efficiency, so as to meet the production quality requirements of products , The welding rotation speed can be adjusted, and the welding spot is smooth and beautiful.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0023] The invention provides a stainless steel barrel welding machine aiming at the problems of low efficiency of manual welding, large fluctuations in quality, poor accuracy and low degree of automation, which affect production efficiency.

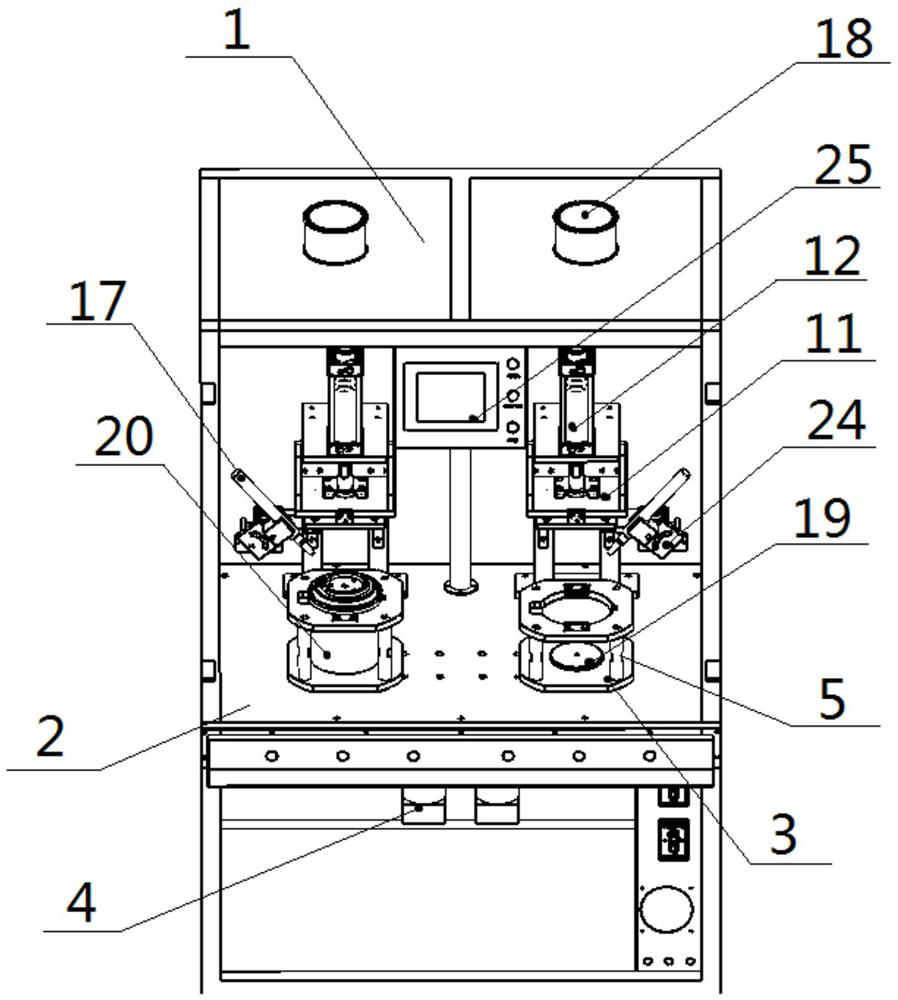

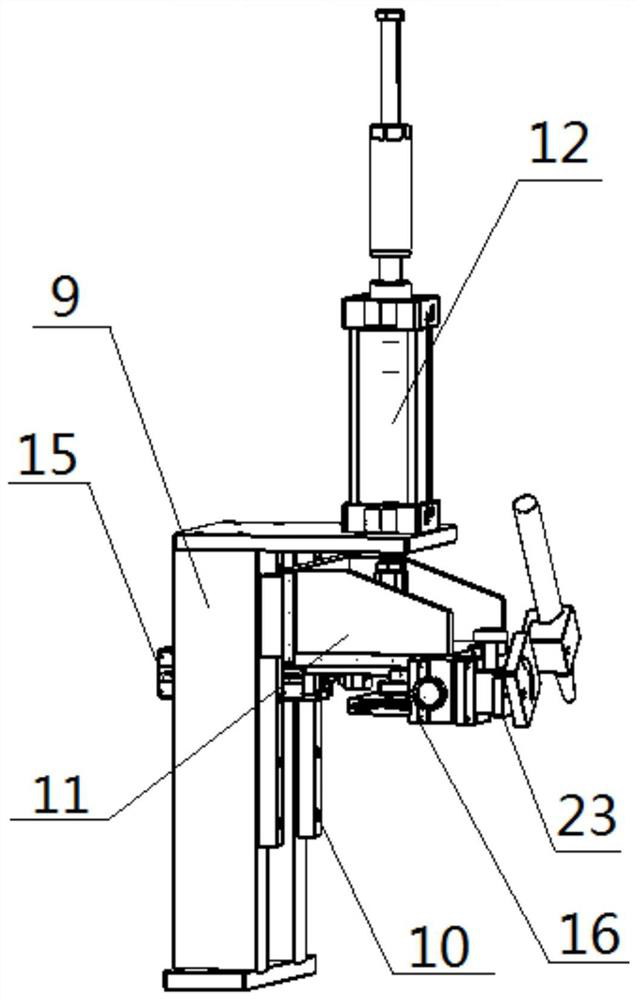

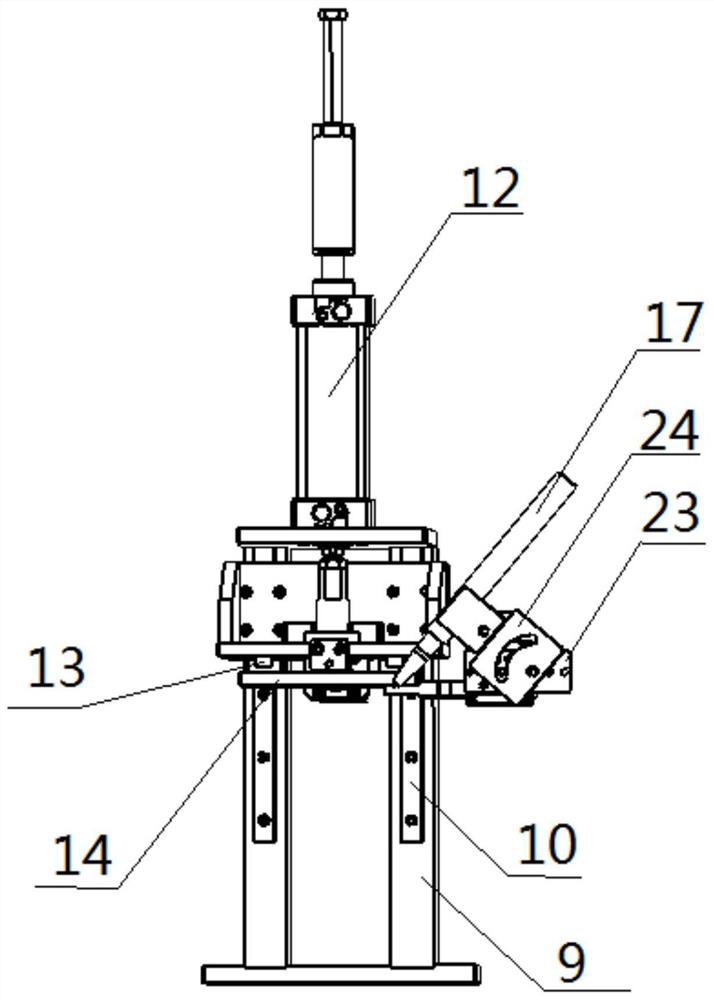

[0024] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a stainless steel barrel welding machine, including: a welding cabinet 1, an operating platform 2 is arranged in the welding cabinet 1; a fixed rotating assembly, the fixed rotating assembly includes a rotating base 3 and A rotating motor 4, the rotating base 3 is installed on the operating platform 2, the top of the rotating base 3 is provided with a rotating fixed frame 5; the bottom of the rotating base 3 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com