Stacking unit, stacking machine and stacking machine control method

A control method and palletizer technology, applied in the field of palletizer and palletizer control, and palletizing unit, can solve problems such as incineration in storage areas, spontaneous combustion of goods, fire spread, etc., and achieve the effect of enhancing the fire extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

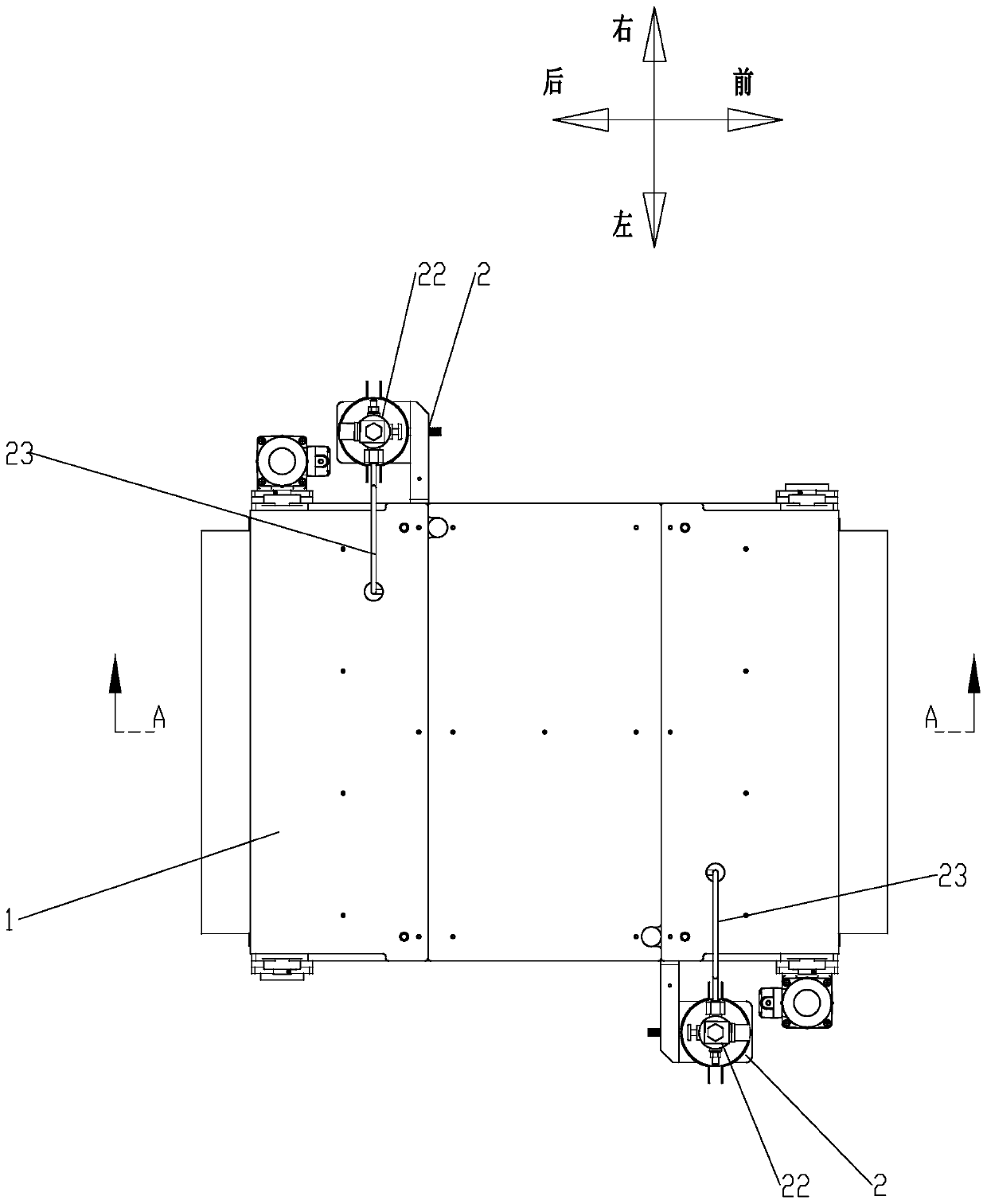

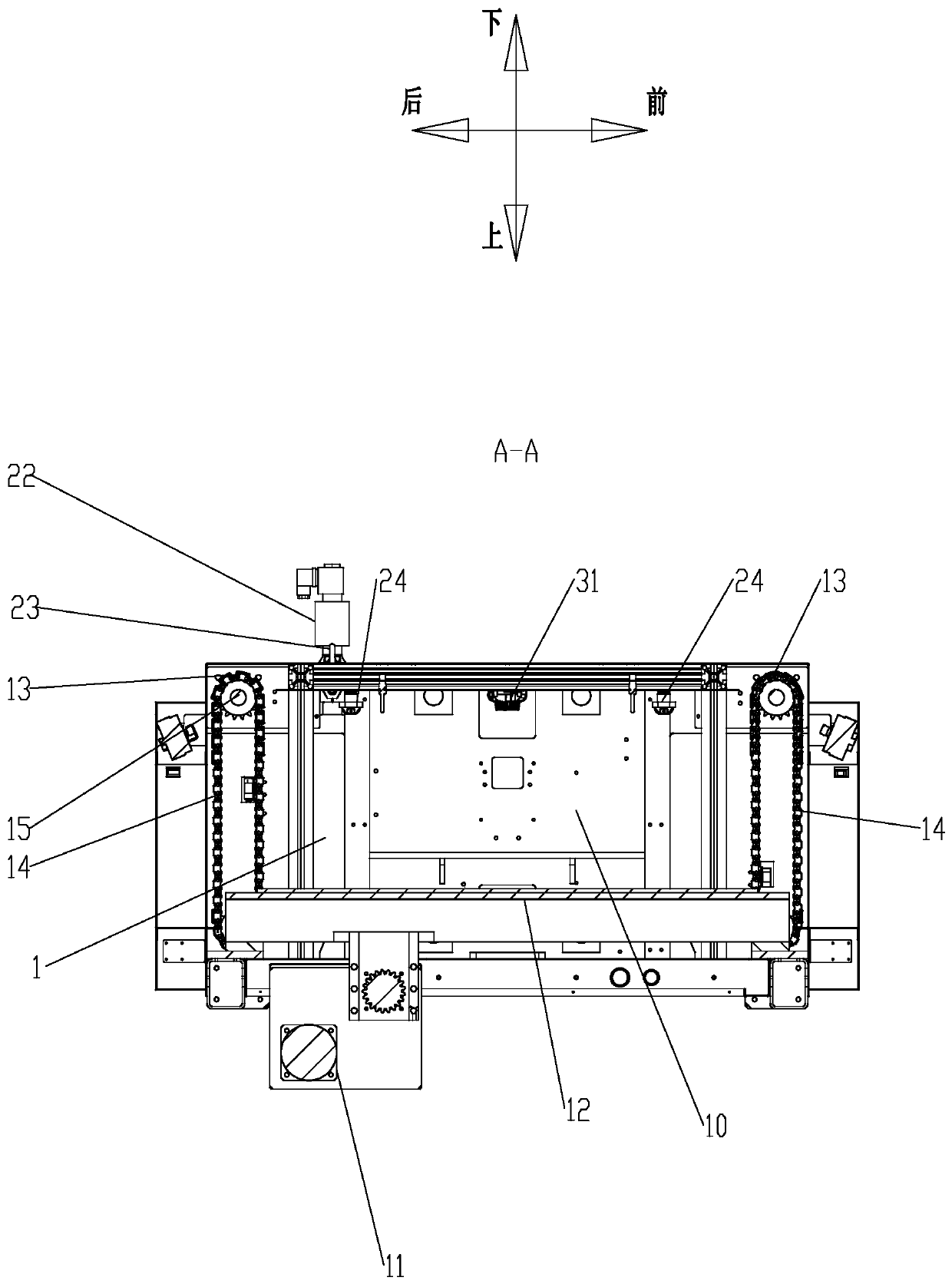

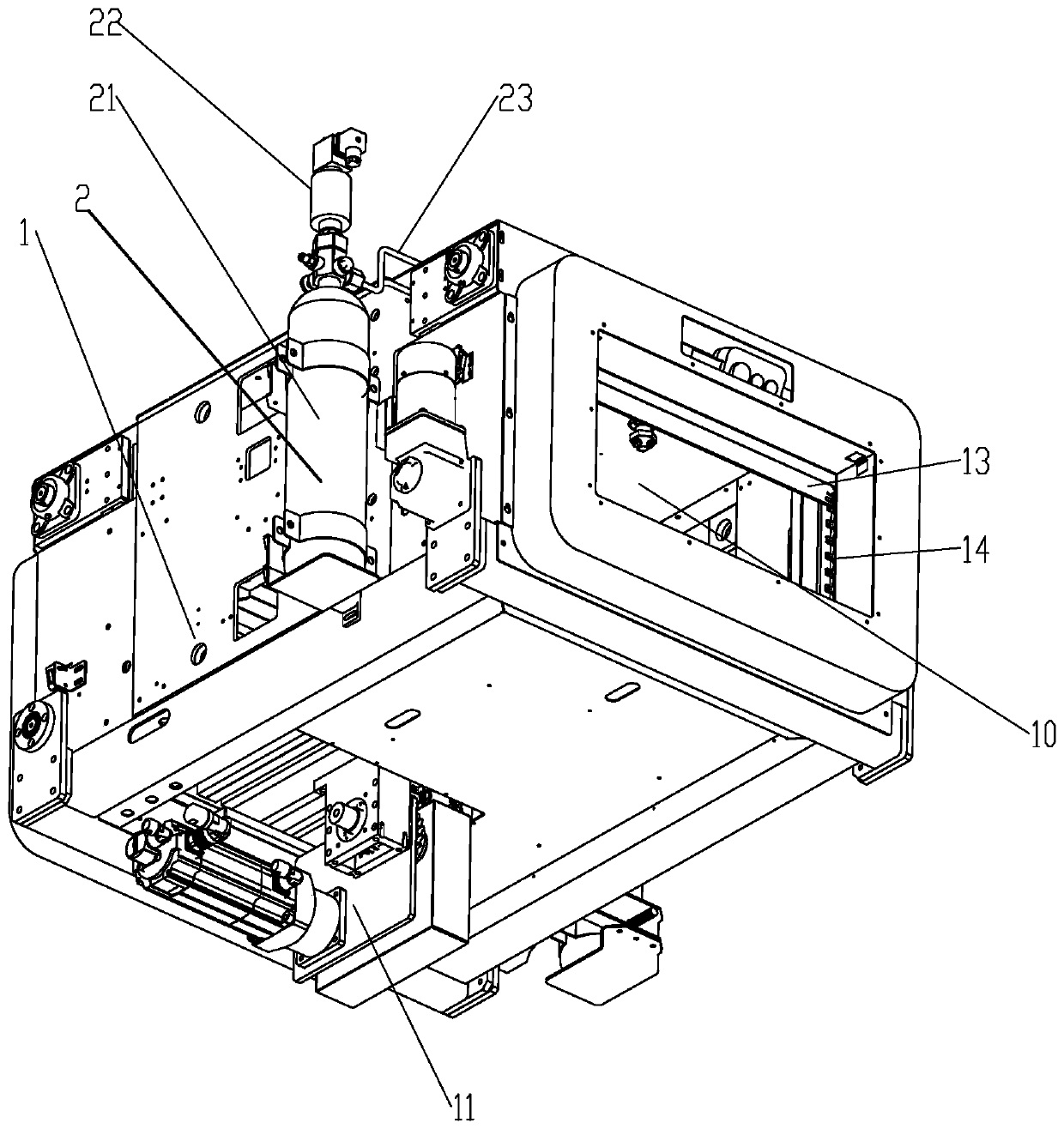

[0034] refer to Figure 1-Figure 4 , a palletizing unit, comprising: a freight device 1, a fire-fighting device 2, a fire detection device 3 and a control device; the freight device 1 is provided with an inner cavity 10 for accommodating goods; the fire-fighting device 2 is located on one side of the freight device 1, The fire-fighting device 2 communicates with the inner cavity 10, and the fire detection device 3 is located on the upper side of the inner cavity 10; the control device can control the fire-fighting device 2 to spray fire extinguishing agent to the inner cavity 10, and the control device is electrically connected with the fire detection device 3, and the control device is connected with the fire detection device 3. The fire fighting device 2 is electrically connected.

[0035] Applying the palletizing unit of this embodiment, since the freight device 1, the fire-fighting device 2, the fire detection device 3 and the control device are all arranged on the fork, w...

Embodiment 2

[0050] On the basis of Embodiment 1, this embodiment provides a palletizer, which includes the palletizing unit in Embodiment 1, and also includes a second drive mechanism 11 and a pallet fork 12, and the pallet fork 12 is located inside the inner cavity 10 , the pallet fork 12 can slide along the front-back direction of the inner cavity 10 under the drive of the second drive mechanism 11 .

Embodiment 3

[0052] On the basis of Embodiment 2, this embodiment provides a palletizer control method for controlling the palletizer in Embodiment 2, which includes the following steps: S1, the fire detection device 3 detects a fire signal, And transmit it to the control device; S2. After receiving the fire signal, the control device controls the fire fighting device 2 to spray fire extinguishing agent into the inner cavity 10 .

[0053] Because the fire detection device 3 and the fire-fighting device 2 are all located on the palletizing unit, it can be ensured that the fire is accurately and timely discovered; In the prior art, the method of transporting the goods on fire to the fire extinguishing station and then extinguishing the fire can extinguish the flame more in time and prevent the fire from spreading.

[0054] Here, the fire signal includes the smoke signal transmitted by the smoke sensor 31 and / or the high temperature signal transmitted by the temperature sensor 32; The detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com