Steel frame fixing device applied to civil engineering

A technology of civil engineering and fixing devices, which is applied in the direction of construction, building structure, and building materials processing, etc., and can solve problems such as the lack of wide applicability of the device and the inconvenient operation of the supporting frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

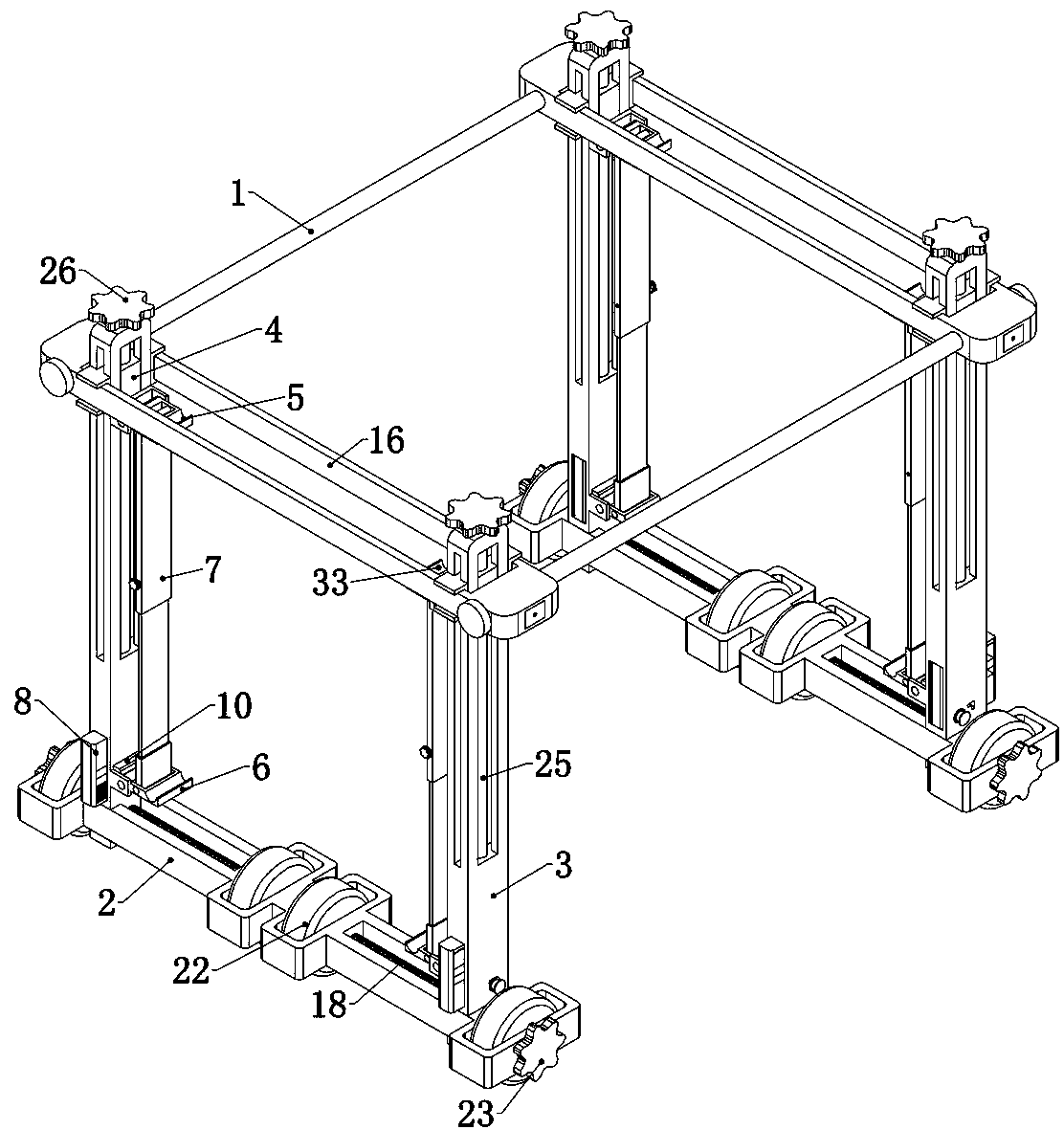

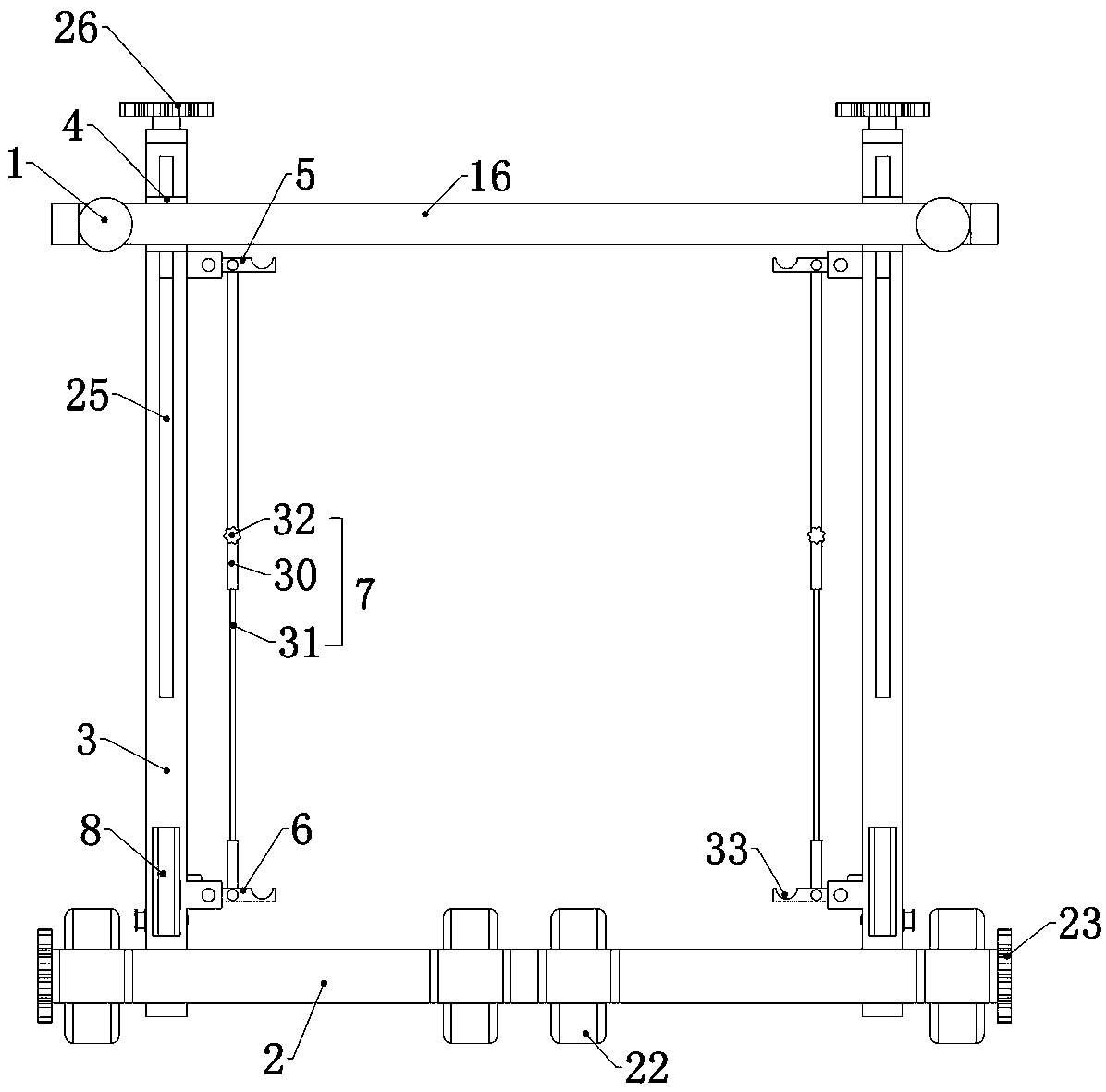

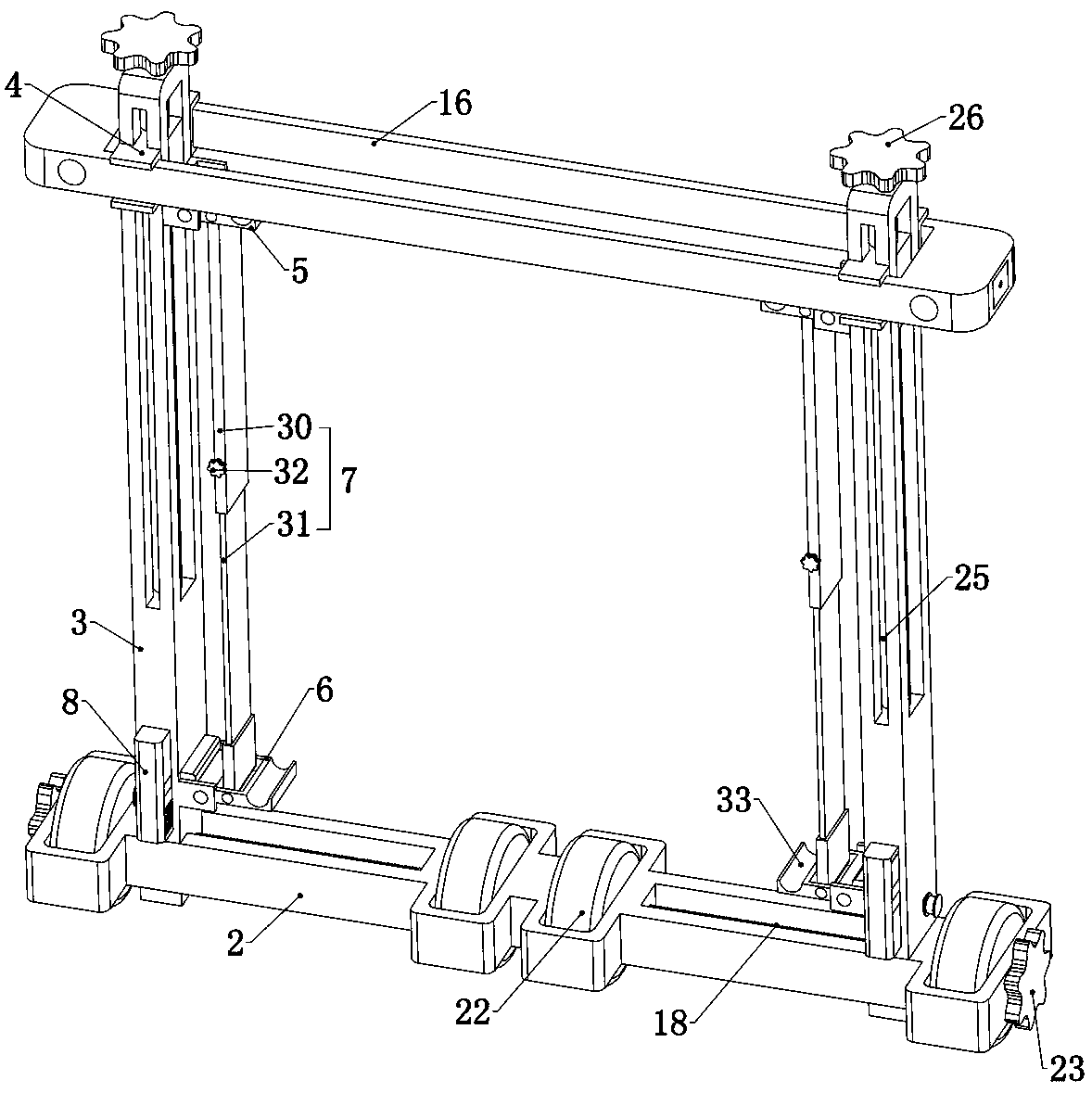

[0041] Embodiment 1, the present invention is a steel frame fixing device for civil engineering, which is characterized in that it includes two support frames, and two sliding shafts 1 are slidably connected between the two support frames, and the two support frames have exactly the same structure, All of them can slide along the sliding shaft 1;

[0042] The supporting frame includes a walking beam 2. The walking beam 2 is the fixed foundation of the subsequent structure of the supporting frame. It is located below the main reinforcement of the beam and column when in use. The walking beam 2 is slidingly connected with two vertical beams 3 left and right. The two vertical beams 3 slide up and down and are connected with a movable base 4. Specifically, refer to figure 1, the walking beam 2 is provided with two vertical beams 3 chute, the lower ends of the two vertical beams 3 are slidingly connected in the two vertical beams 3 chute respectively, and the two vertical beams 3 a...

Embodiment 2

[0046] Embodiment two, on the basis of embodiment one, refer to Figure 11 One end of the contact connection between the locked slider 15 and the sliding shaft 1 is fixedly connected with a rubber pad 17, and the rubber pad 17 is set so that when the locked slider 15 is pressed on the sliding shaft 1, the locked slider 15 There is greater friction between the sliding shaft 1 and the sliding shaft 1, thereby facilitating the fixing of the sliding shaft 1.

Embodiment 3

[0047] Embodiment three, on the basis of embodiment one, each of the supporting frames includes a double-ended screw 18, and the double-ended screw 18 is rotatably connected to the walking beam 2, and the double-ended screw 18 passes through the lower ends of the two vertical beams 3 and the two vertical beams 3 are threaded. Specifically, the lower ends of the two vertical beams 3 are provided with threaded holes for the vertical beams 3. The double-ended Both ends of the screw 18 pass through the threaded holes of the two vertical beams 3 respectively, and the rotation of the double-ended screw 18 can drive the two vertical beams 3 to approach or move away from each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com