Casting device, lining trolley and pouring process

A technology for lining trolleys and pouring pipes, which is applied in shaft lining, tunnel lining, shaft equipment, etc., can solve problems such as voids, and achieve the effect of reducing internal voids

Active Publication Date: 2022-05-31

湖南帝星智能科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Based on this, it is necessary to provide a pouring device, lining trolley and pouring process for the problems of pouring voids and voids in the existing vault position concrete pouring

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

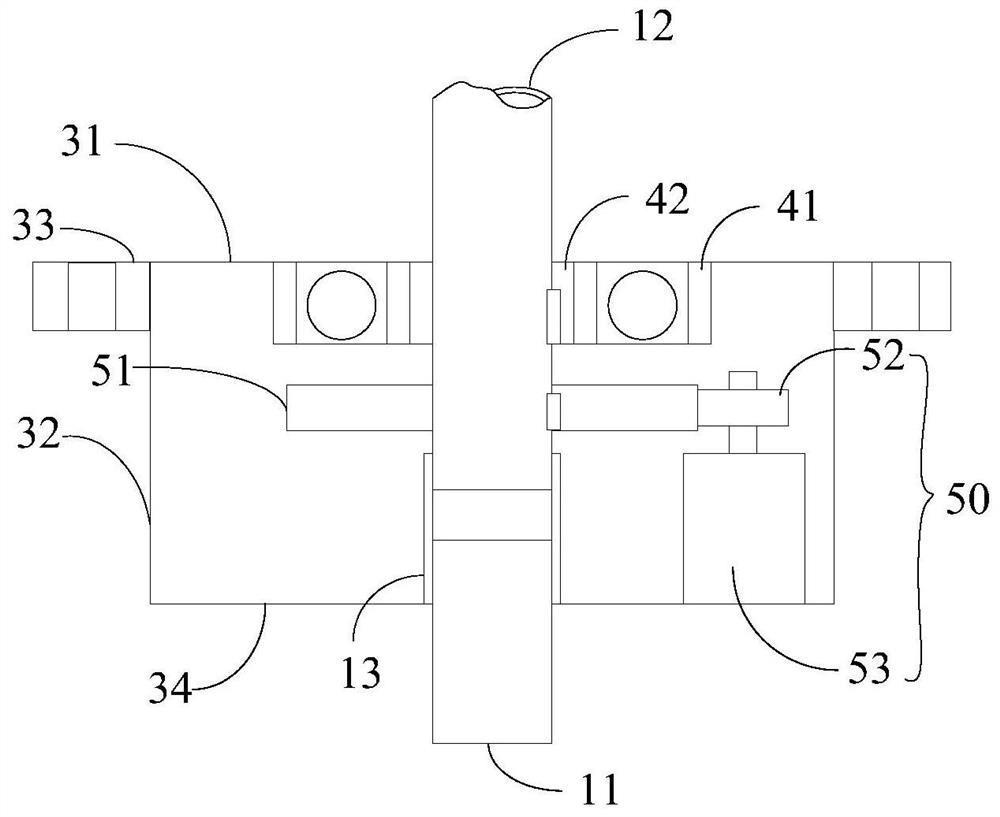

[0028] Further, the fixed seat 30 includes a housing 32 and a mounting foot 33 arranged outside the housing 32.

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

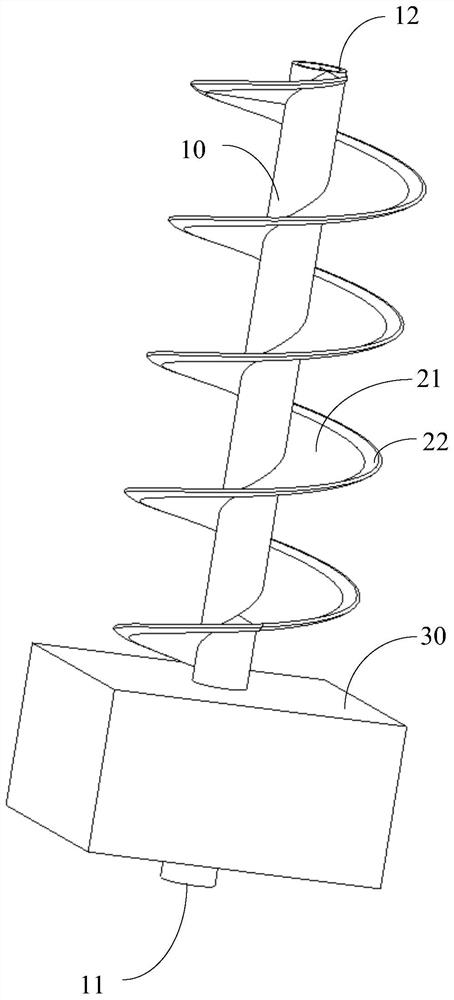

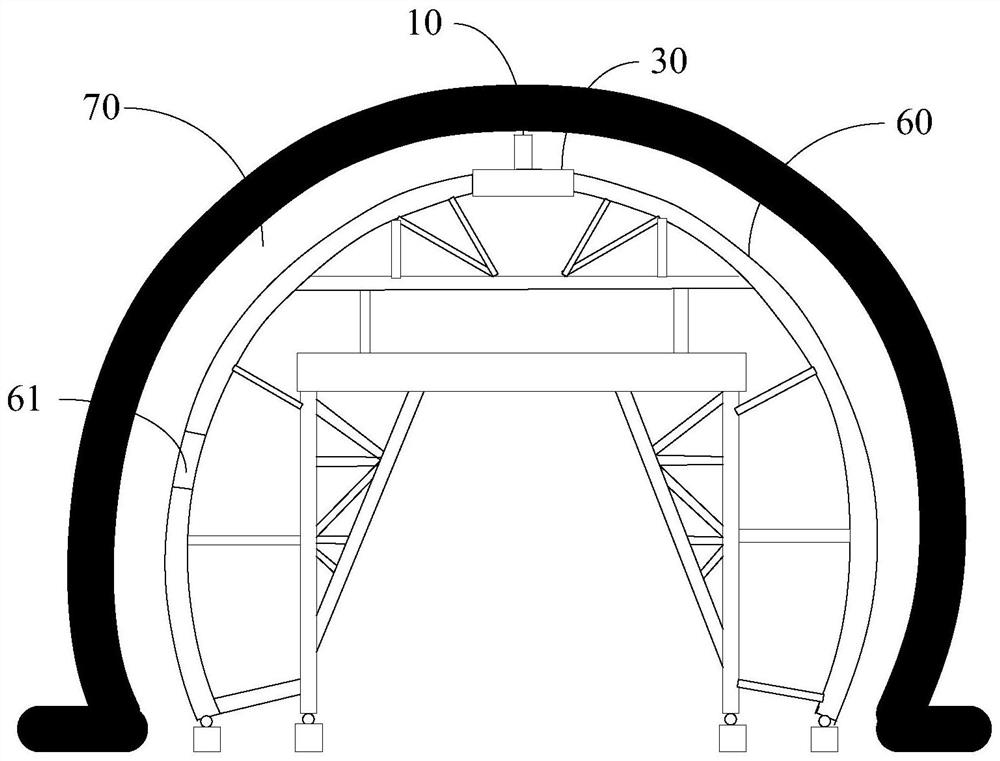

The invention discloses a pouring device, which is applied to a lining trolley. The lining trolley includes an arc-shaped formwork, and a pouring window is arranged on the arc-shaped formwork, and the pouring device includes a fixing device adapted to the pouring window. a seat, a pouring pipe arranged on the fixed seat, a spiral blade arranged on the outer periphery of the pouring pipe, and a driving component for driving the spiral plate to rotate. The invention solves the problem of voids existing in concrete pouring at the existing arch top position.

Description

Pouring device, lining trolley and pouring process technical field [0001] The present invention relates to the field of tunnel construction, in particular to a pouring device, a lining trolley and a pouring process. Background technique Secondary lining is the formwork concrete or reinforced concrete lining that tunnel engineering construction performs on the inner side of initial support, It forms a composite lining together with the initial support. Compared with the initial support, the secondary lining refers to the initial support in the tunnel. Under the condition of protection, the inner lining built with concrete and other materials can strengthen the support, optimize the route of the waterproof and drainage system, and improve the It can improve the appearance and facilitate the setting of communication, lighting, monitoring and other facilities to meet the requirements of modern highway tunnel construction. Now expressway and railway engineering mostly in...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E21D11/10

CPCE21D11/105E21D11/102Y02E10/20

Inventor 胡仕成刘晓宏胡盼

Owner 湖南帝星智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com