An assembly process of inner fine-tuning cylindrical battery core

A cell assembly, cylindrical technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of denser cells, small supporting force, and reduced internal gaps, so as to reduce battery heating and prolong battery life. The effect of battery life, current output concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

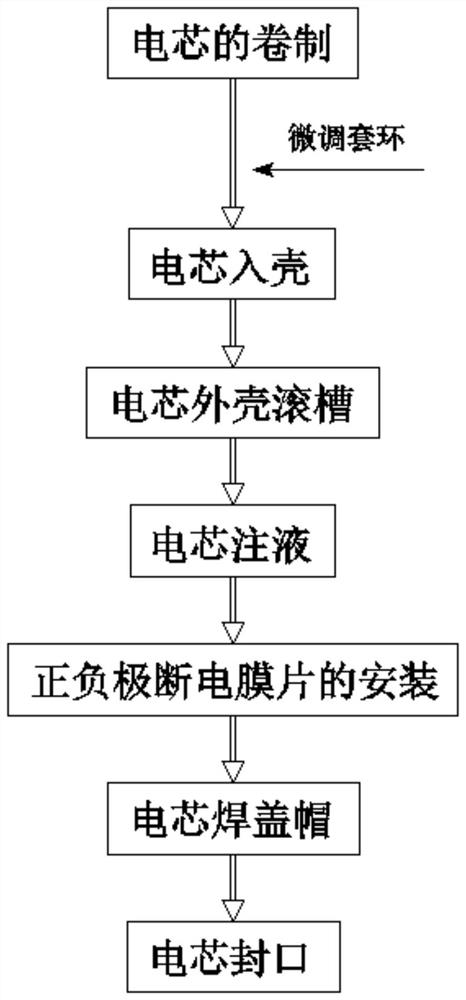

[0054] see Figure 1-4 , an internal fine-tuning cylindrical cell assembly process, comprising the following steps:

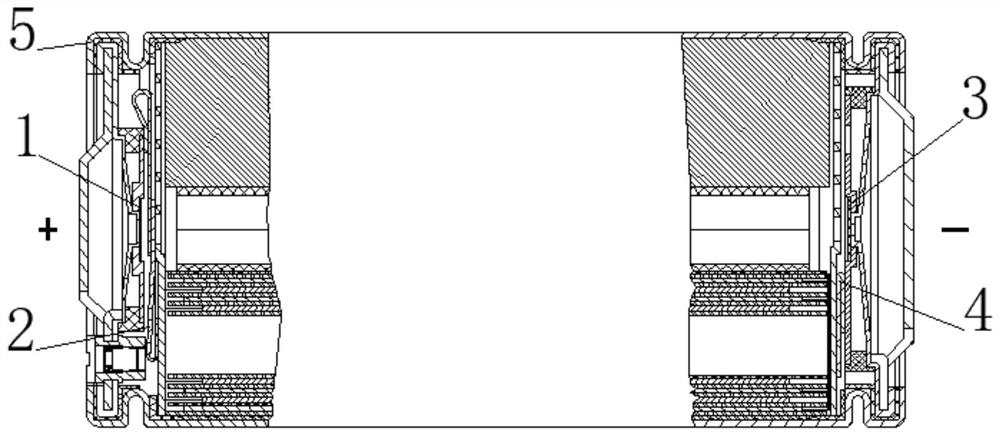

[0055] S1, see Figure 5 , firstly weld the positive pole tab 2 and the negative pole tab 4 to different pole pieces respectively to obtain the positive pole piece and the negative pole piece, put them in the order of positive pole piece-diaphragm-negative pole piece-diaphragm from top to bottom, and make into a cylindrical cell;

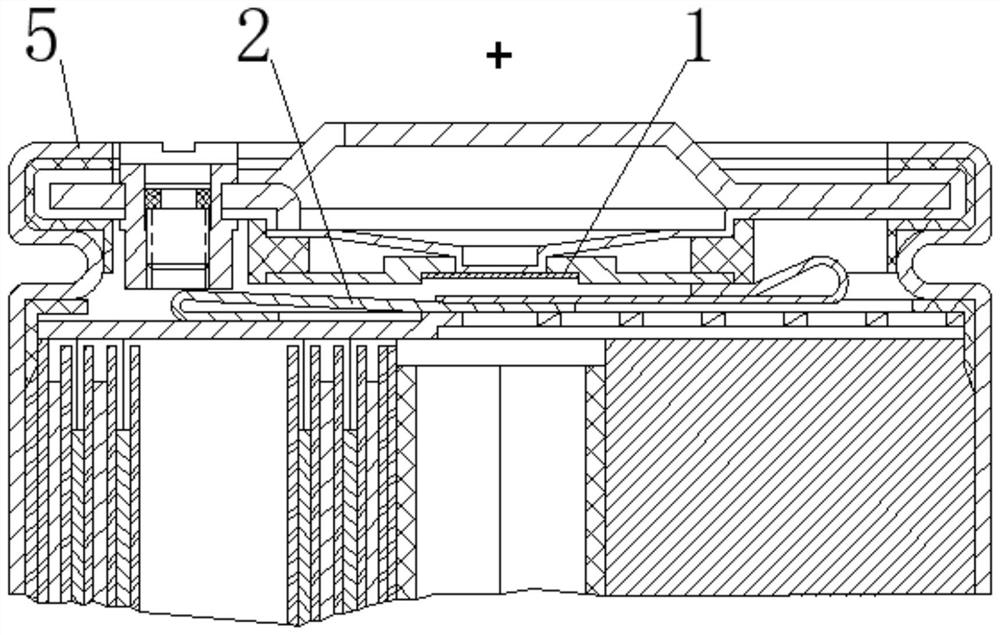

[0056] S2. Inserting the electric core into the shell, firstly, according to the fine-tuning collar in the external shell 5, determine the shell-entry direction and angle of the external shell 5, and then install the electric core into the external shell 5 according to the direction and angle, and then Turn the fine-tuning collar to fine-tune the relative position between the cell and the fine-tuning collar, the specific operation is:

[0057] S21. First determine the obvious recessed part visible to the naked eye on the surface o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com