Protective bearing device with sliding blocks for eliminating clearance

A technology for protecting bearings and eliminating gaps, which is applied in the direction of bearing assembly, bearings, bearing components, etc., and can solve problems such as automatic protection of rotors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

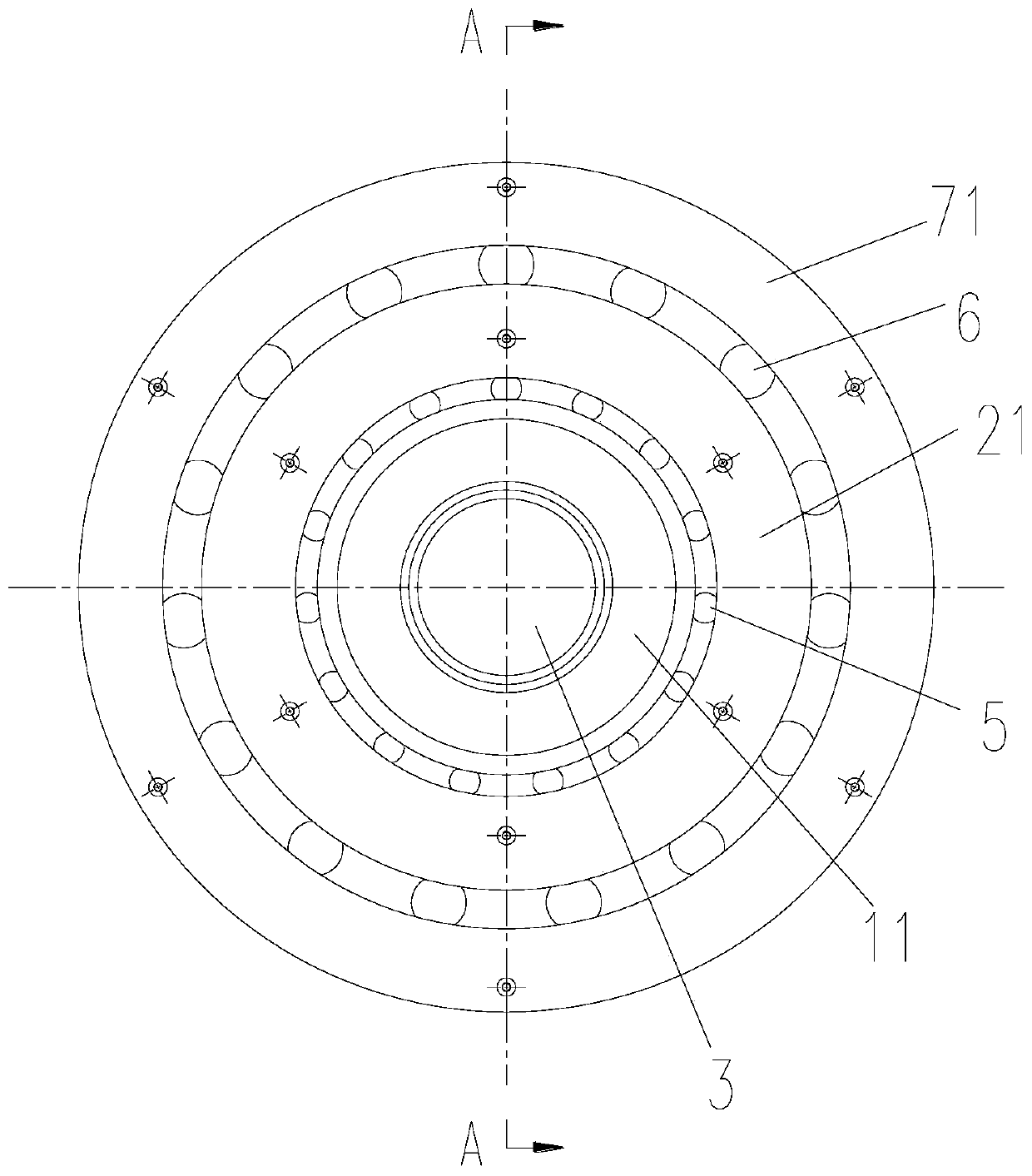

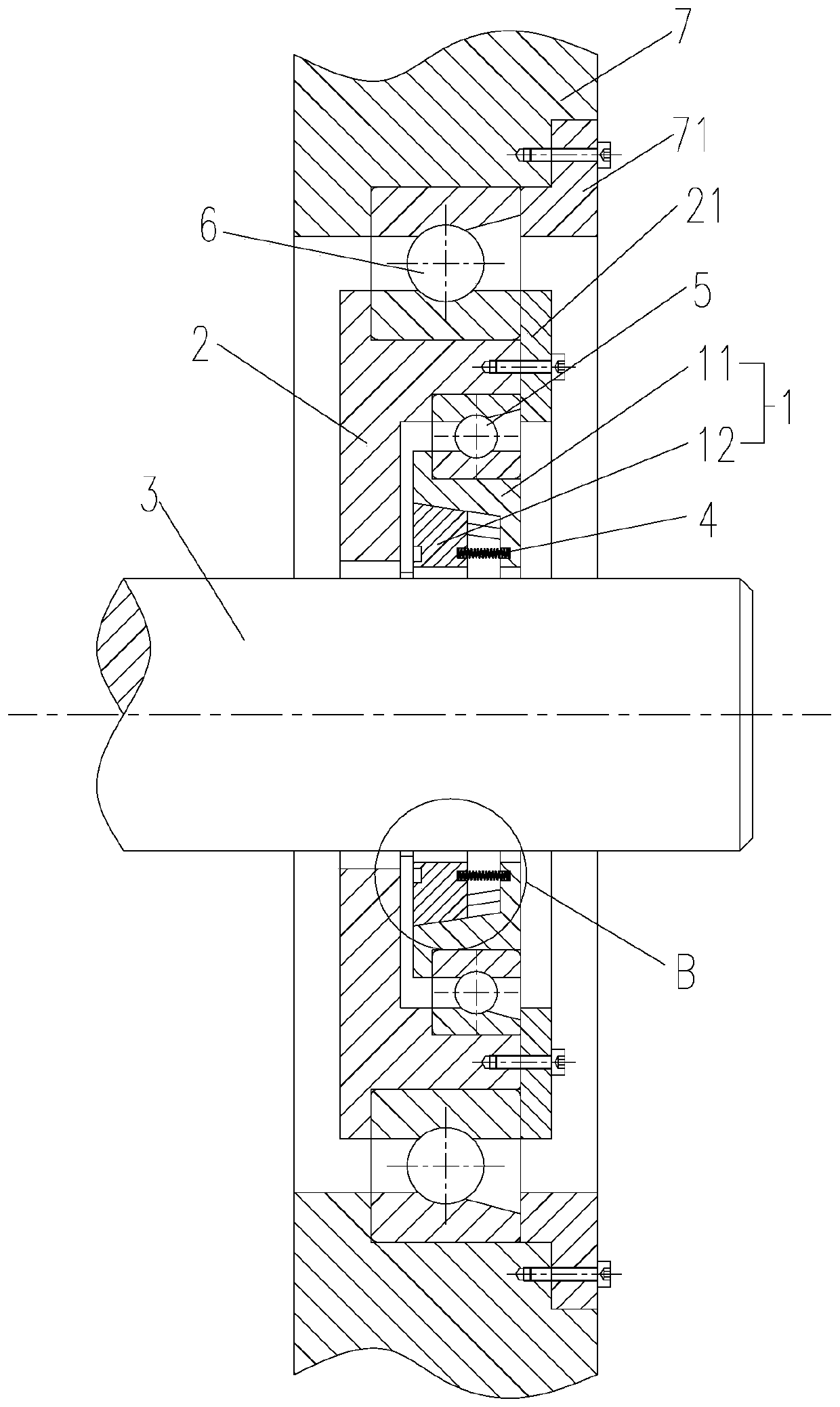

[0043] Such as Figure 1-11 As shown, this embodiment proposes a sliding block clearance protection bearing device, which includes a support assembly 1 and a drive element 2, wherein the support assembly 1 and the drive element 2 are both clearance-fitted on the outer periphery of the rotor 3, and when the rotor 3 loses When electricity is dropped, the driving member 2 can push the support assembly 1 to connect with the rotor 3, so as to support the rotor 3.

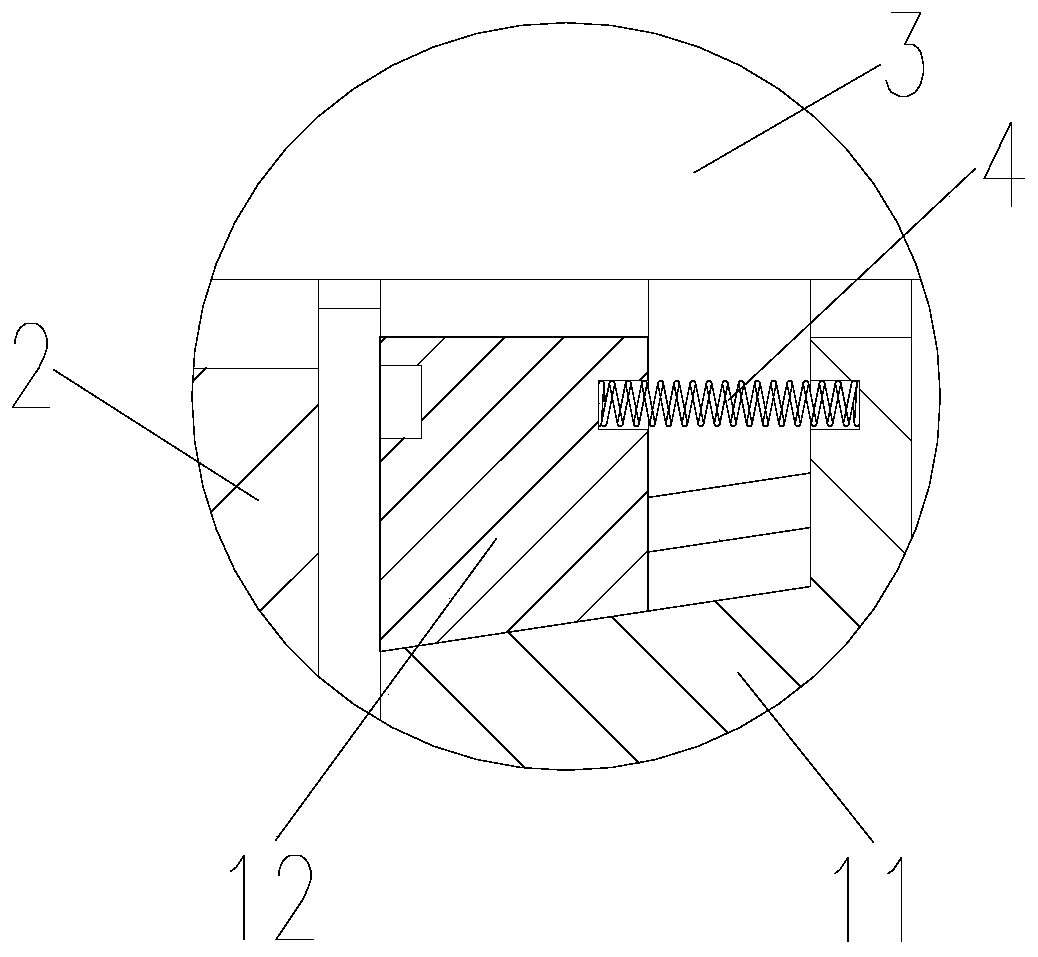

[0044] The support assembly 1 includes a built-in part 11 and at least two sliders 12. The built-in part 11 is clearance-fitted on the outer periphery of the rotor 3. One end of the built-in part 11 has a chute 111 communicating with the rotor 3. At least two sliders 12 are Distributed in the chute 111, and slide in the chute 111 in the direction inclined to the axis of the rotor 3, when the slider 12 slides in the chute 111, the inner end of the slider 12 is in contact with or away from the rotor 3 . Specifically, the...

Embodiment 2

[0053] This embodiment is basically the same as Embodiment 1, the only difference is that the rotor 3 is provided with a third bearing 8, and the slider 12 is arranged on the outer periphery of the third bearing 8 with a gap. Under the push of the driving member 2, the slider 12 The supporting portion of the third bearing 8 is in contact with the outer ring of the third bearing 8 to support the third bearing 8 and thereby realize the support of the rotor 3 .

[0054] Preferably, the outer periphery of the rotor 3 is provided with a stepped surface, and the stepped surface on the rotor 3 cooperates with the sleeve 31 connected thereon to press against the outer periphery of the third bearing 8 to realize the detachable connection of the third bearing 8 . Further preferably, the sleeve 31 is screwed on the outer periphery of the rotor 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com