An arc-interval structure of a contactor

A contactor and arc isolation technology, which is applied in relays, electromagnetic relays, contact housings/screens, etc., can solve the problems of assembly, arc isolation board failure, and labor cost consumption, and achieves reduced assembly difficulty, simple assembly, and high structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

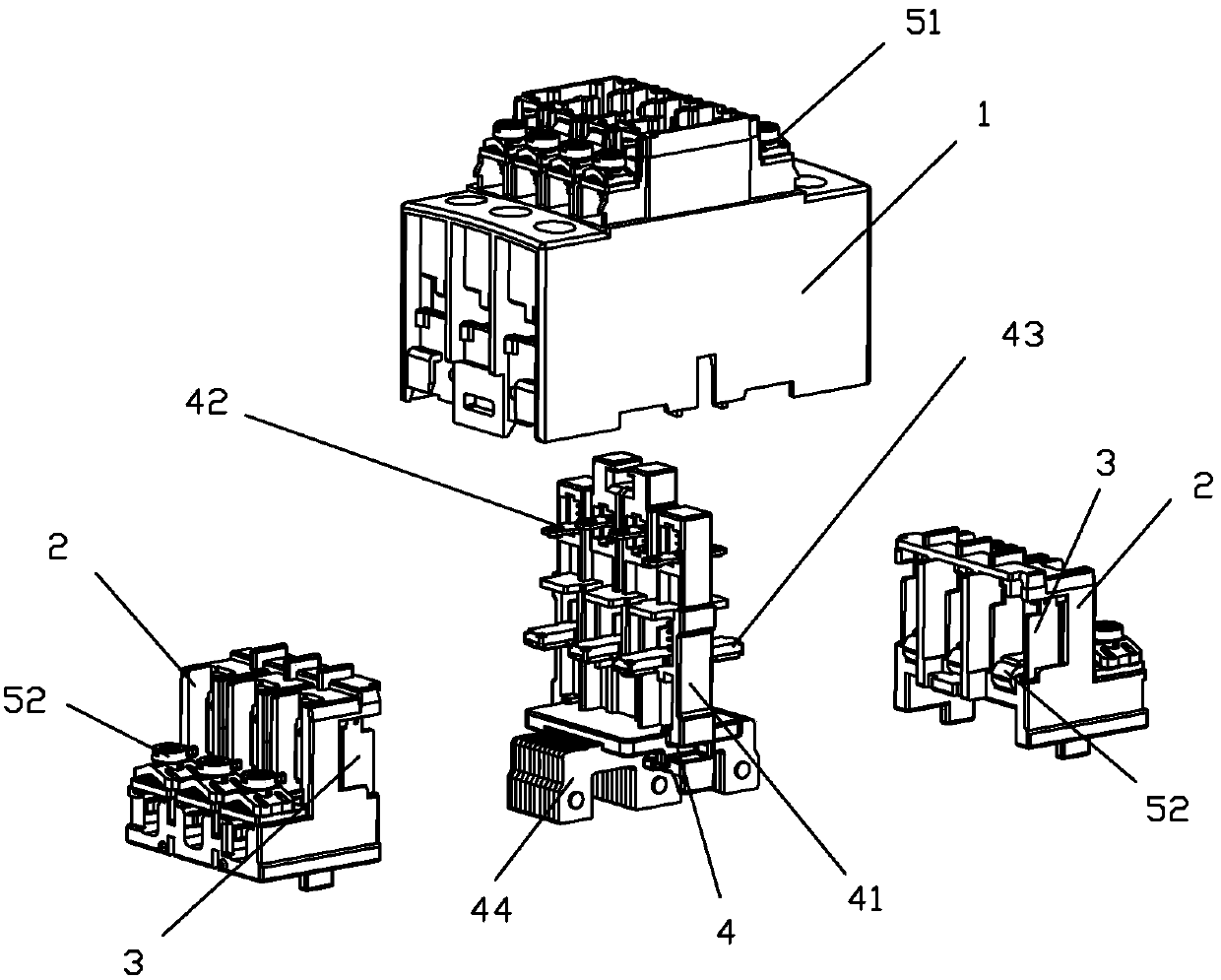

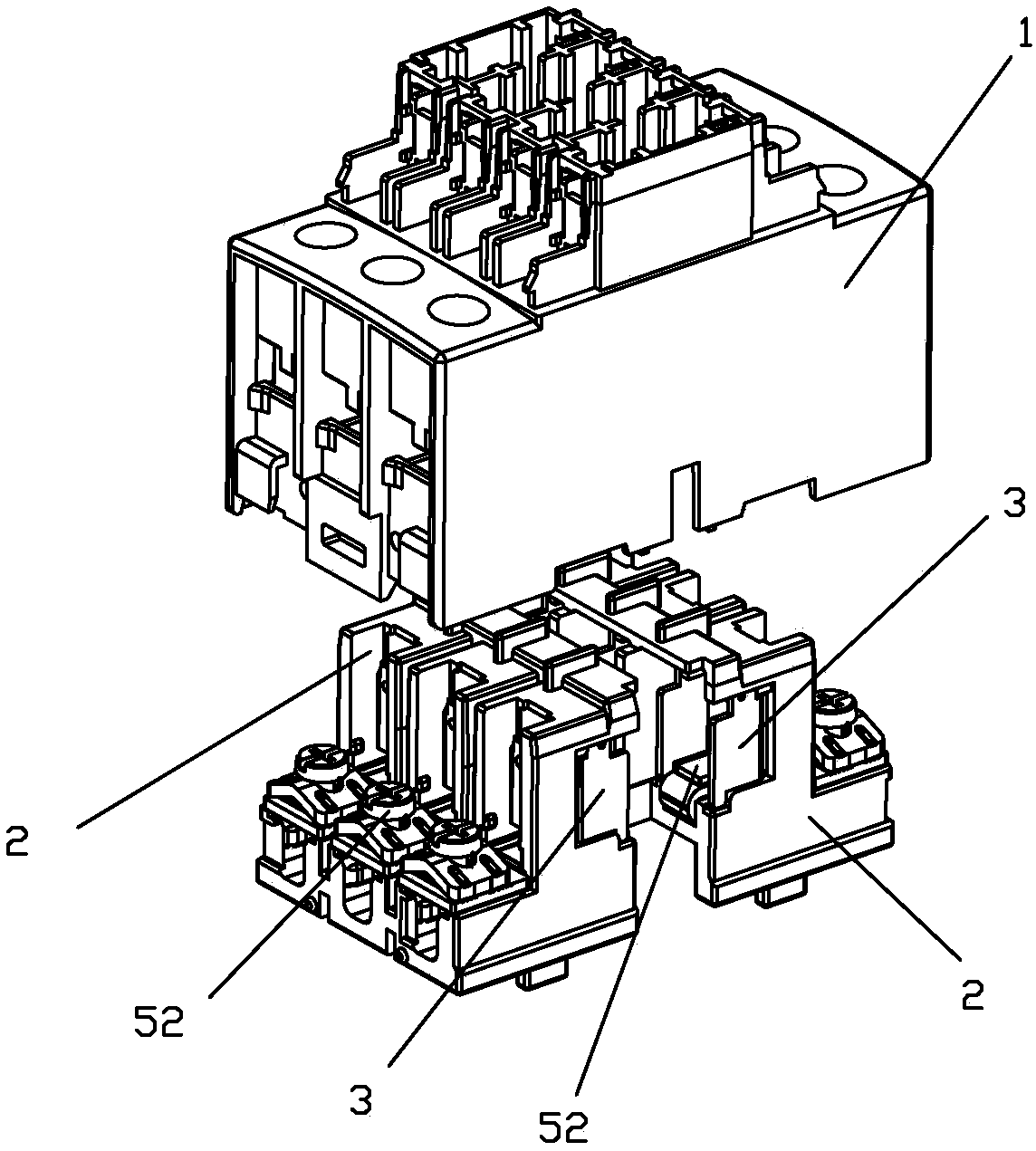

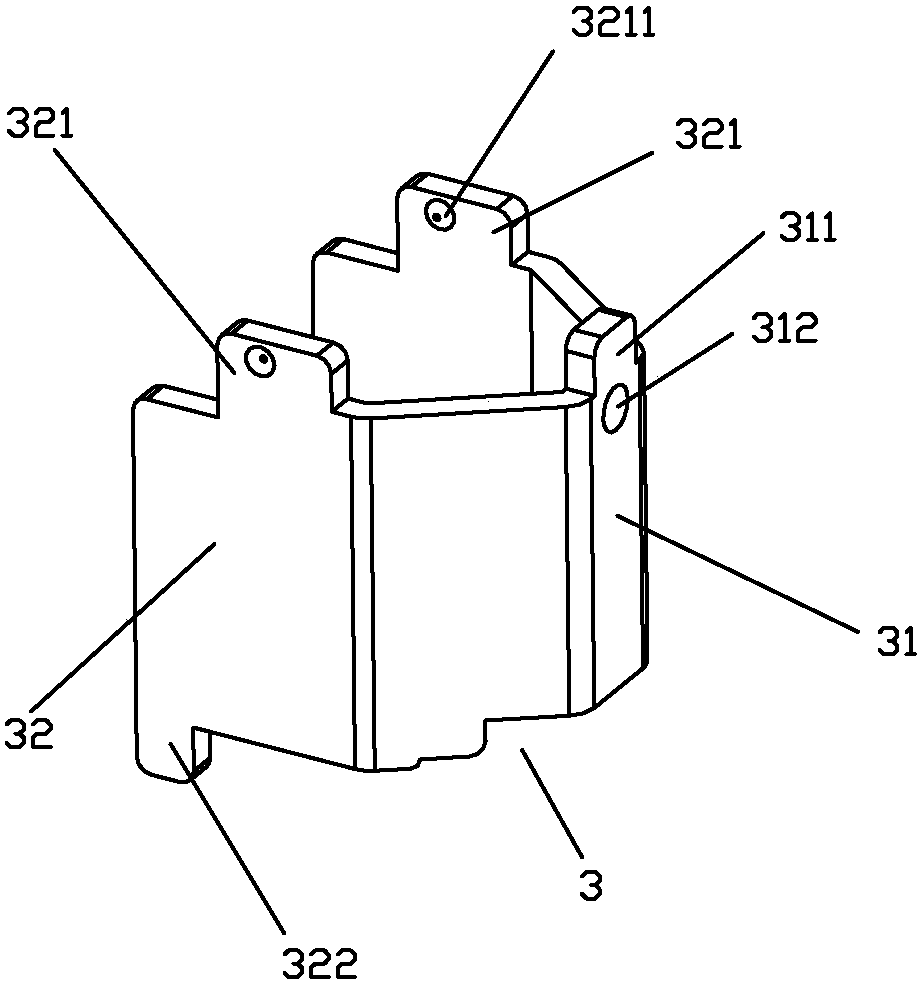

[0041] see Figure 1 to Figure 12 As shown, an arc-breaking structure of a contactor of the present invention includes a first housing for installing auxiliary static contacts, a second housing for installing main static contacts, and several arc-breaking plates 3, so The first casing is set as a large casing 1, and the second casing is two small casings 2 split into independent parts; the opening of the large casing 1 faces downward, and the two small casings 2 are accommodated in the large housing 1 in a left-right relative manner, and a gap is provided between the two small housings 2 for accommodating the moving contact assembly 4, so that the moving contact assembly 4 can be located in the two small housings 2 between; the small housing 2 is provided with several openings 21 facing the cavity 20 of the movable contact assembly 4, to provide active and static contacts in the cavity 20; the arc barrier 3 is inserted into the corresponding chamber 20 of the small casing 2 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com