Device and method for dynamically testing liquid reactive molding shrinkage

A liquid reaction and molding technology, applied in the direction of material thermal expansion coefficient, etc., can solve the problems of test value interference, difficult to obtain reaction shrinkage, etc., to achieve the effect of eliminating errors and increasing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

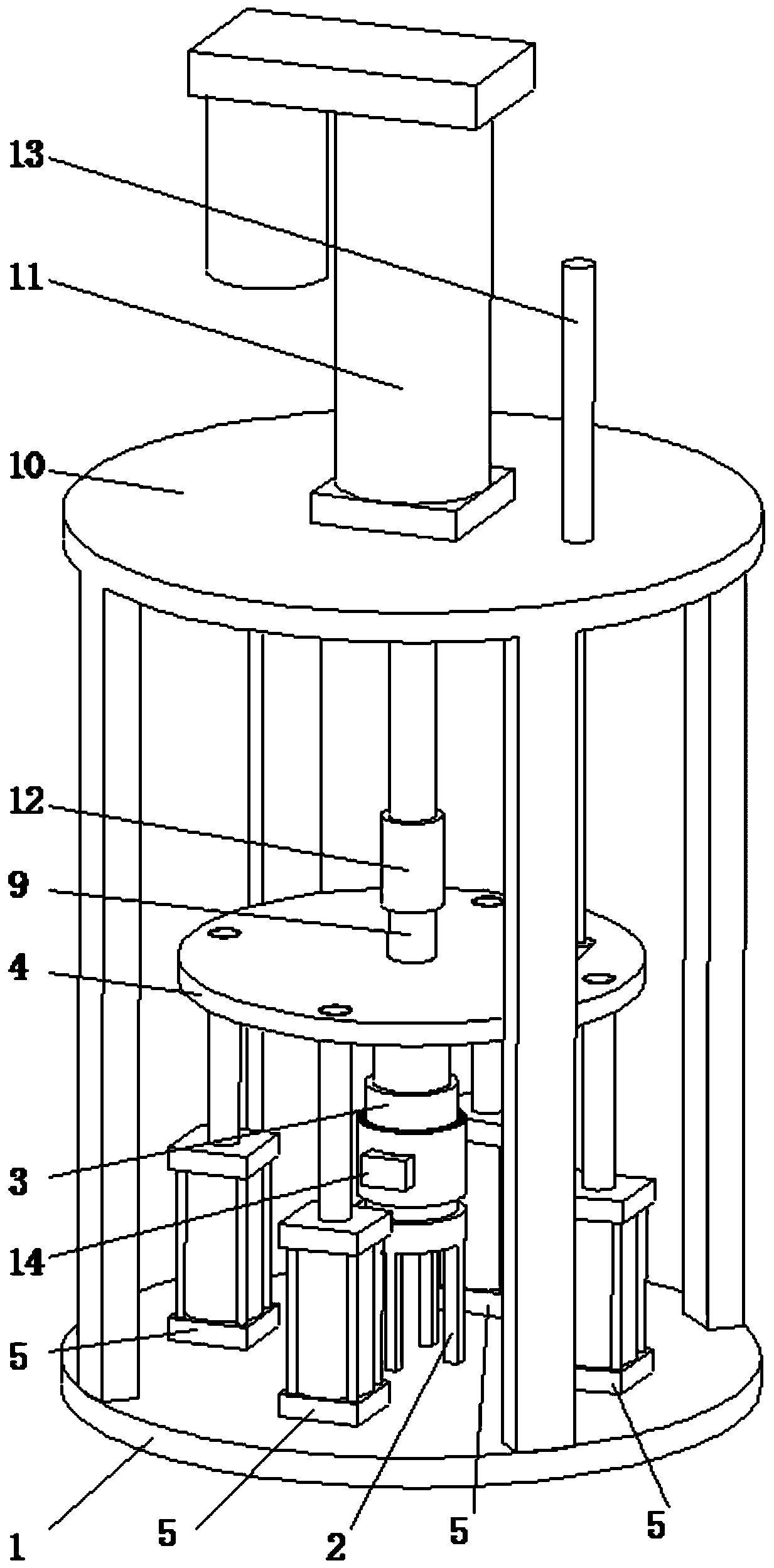

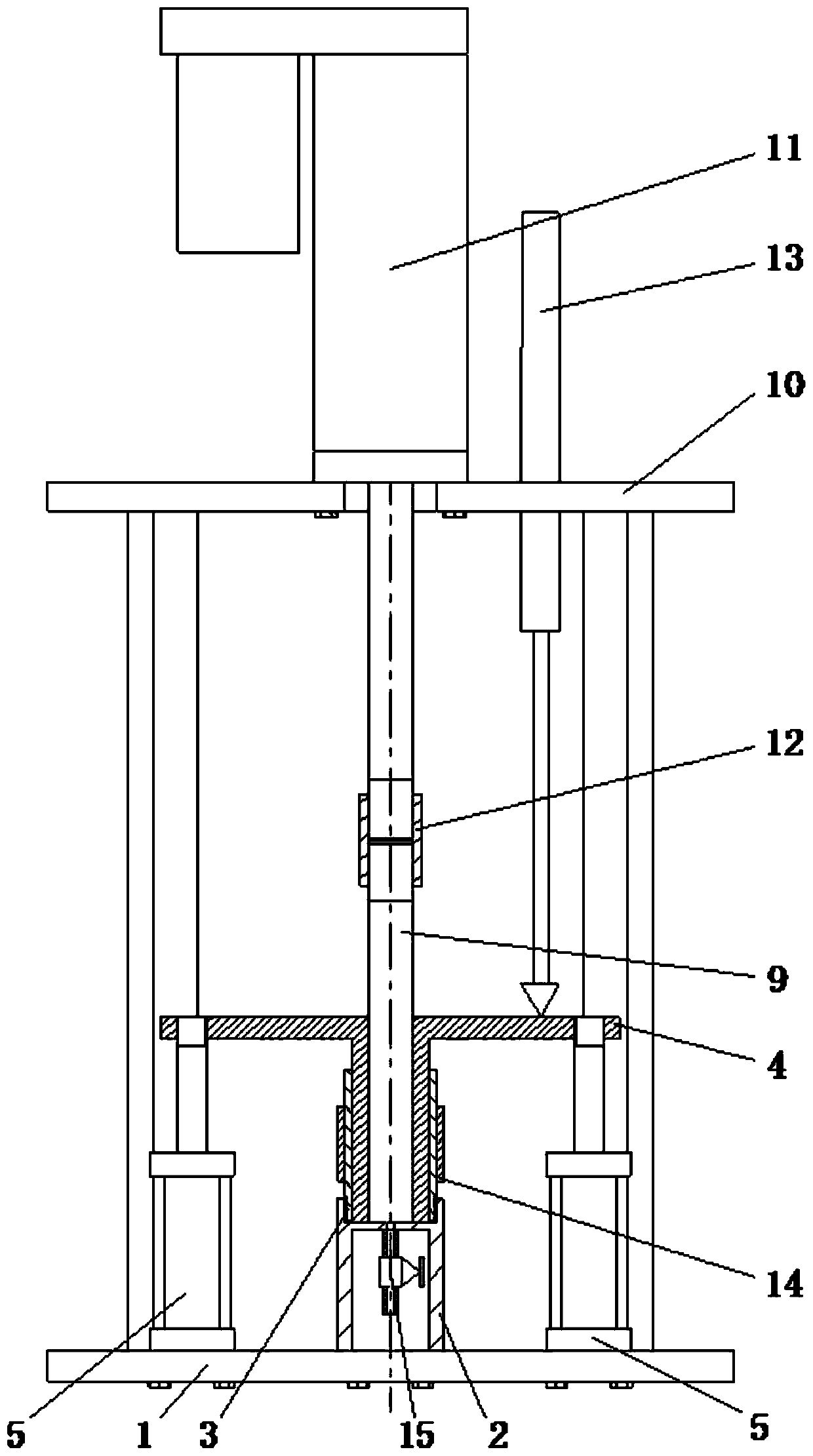

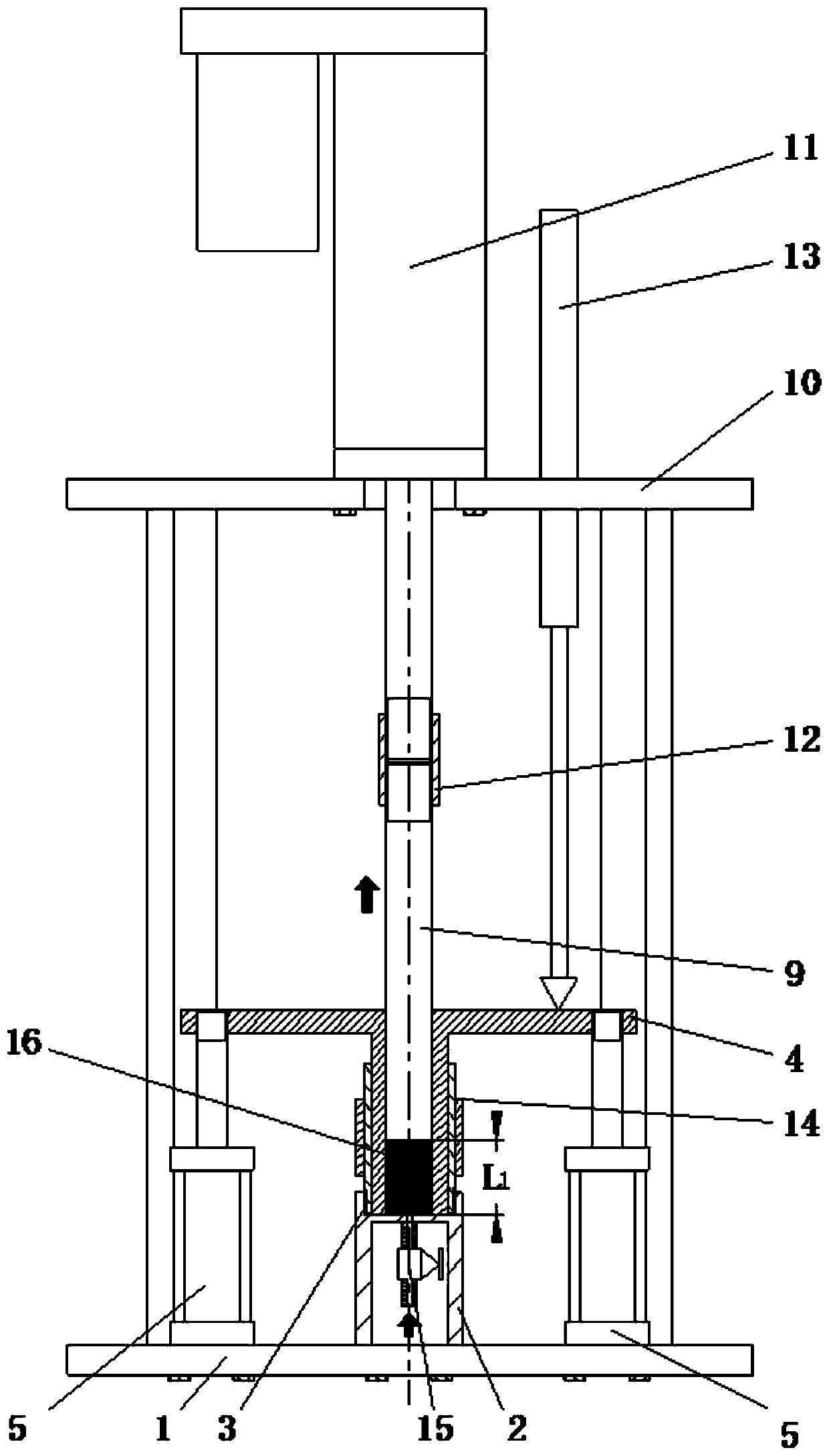

[0020] The present invention proposes a device for dynamically testing liquid reaction molding shrinkage, such as figure 1 ,figure 2, image 3 , Figure 4 , Figure 5 As shown, the module mainly includes: base 1, test chamber fixing seat 2, test chamber 3, annular plunger 4, cylinder 5, sample injection plunger 9, electric cylinder fixing seat 10, electric cylinder 11, coupling 12, The displacement sensor 13, the electric heater 14, the sampling valve 15 and the sample 16 to be tested are composed. Among them, the base 1 is a round thick rigid flat plate, placed on the surface used to place the instrument; the test chamber fixing seat 2 is a metal cylinder with an upright axis, with four legs on the lower part of the cylinder, and a center on the upper surface. A blind hole with internal thread, the bottom surface of the blind hole is flat, and there is a tiny through hole in the center, the four legs of the test cavity fixing seat 2 are welded to the base 1, and the test cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com