Flat cable end tape attaching device and method

A gluing device and film technology, which is applied in the manufacture of wire harnesses, electrical components, circuits, etc., can solve the problems of high energy consumption and low efficiency, and achieve the effects of improving quality, improving work efficiency, and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

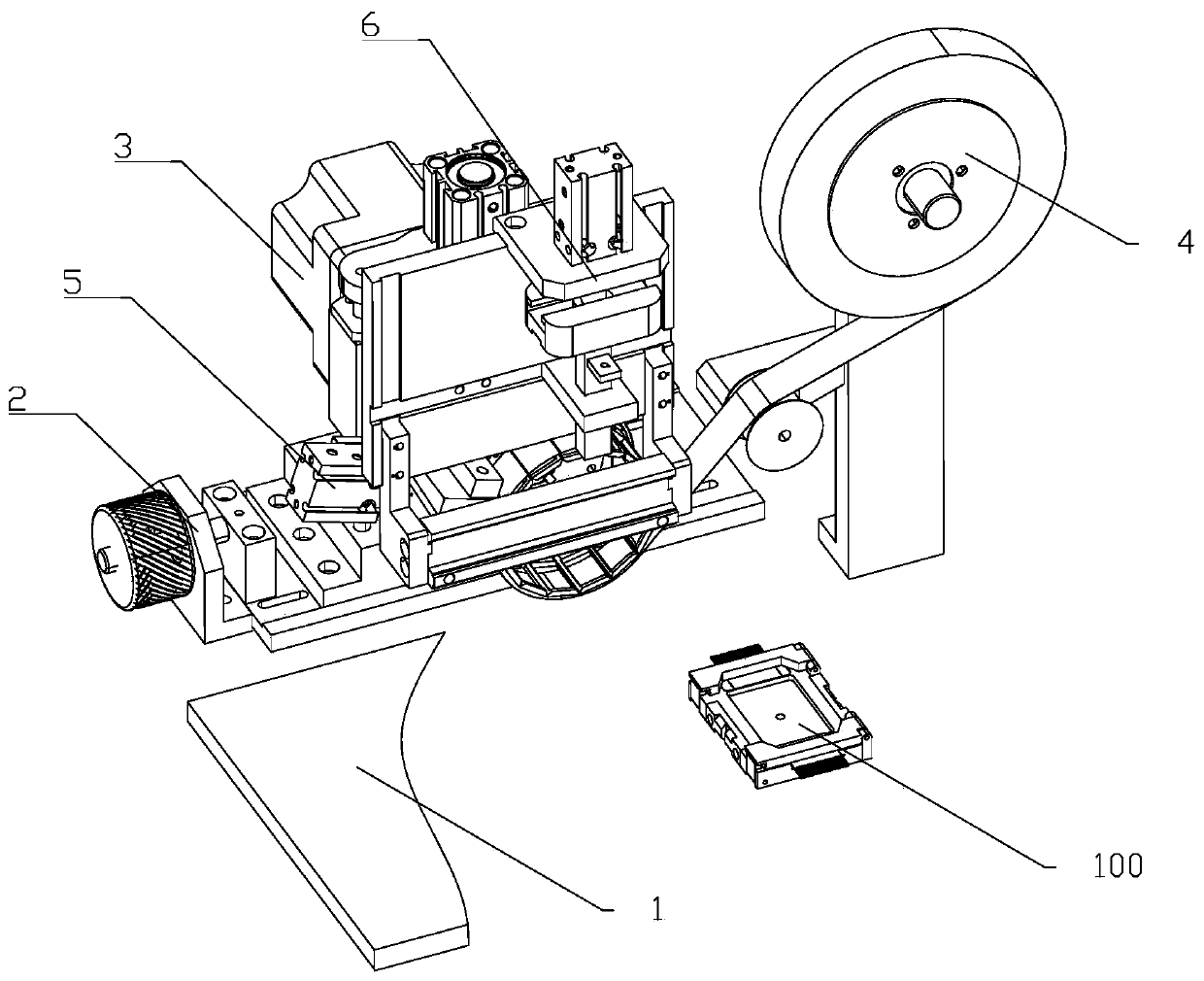

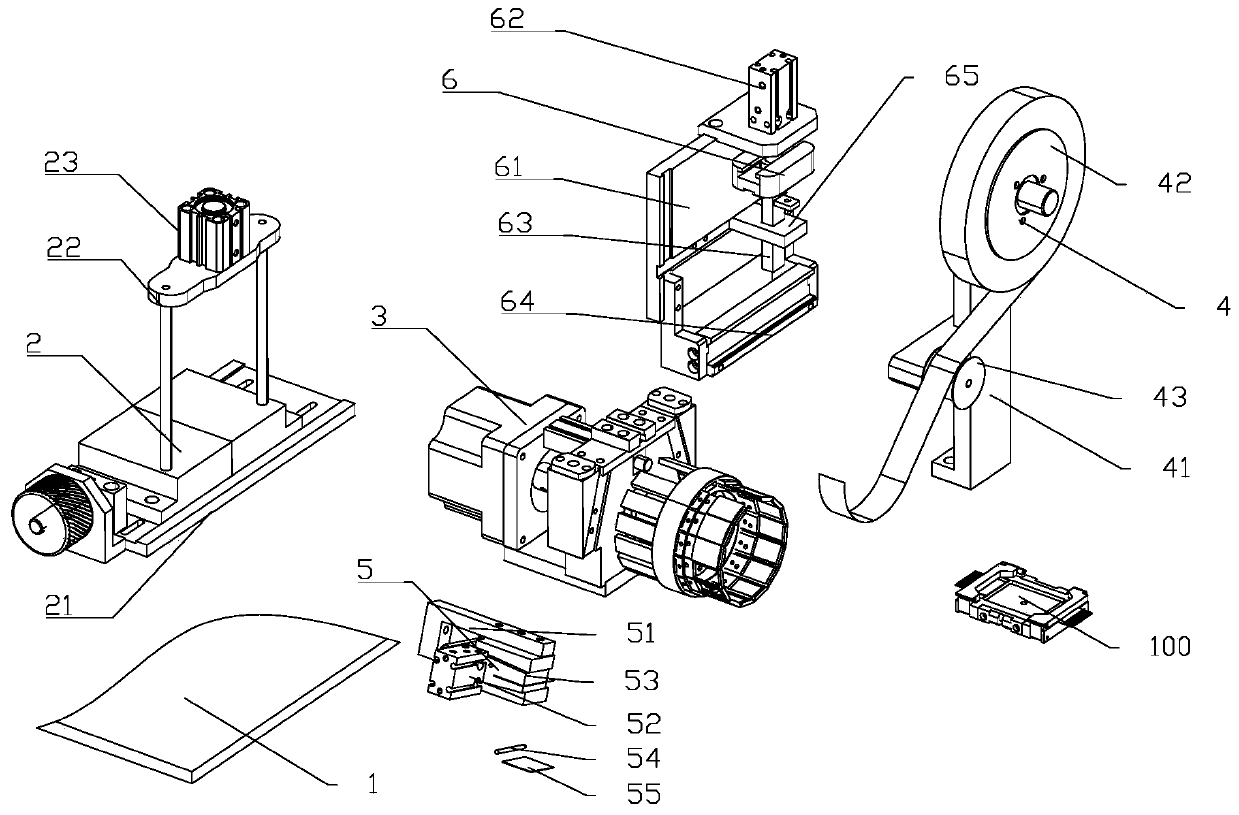

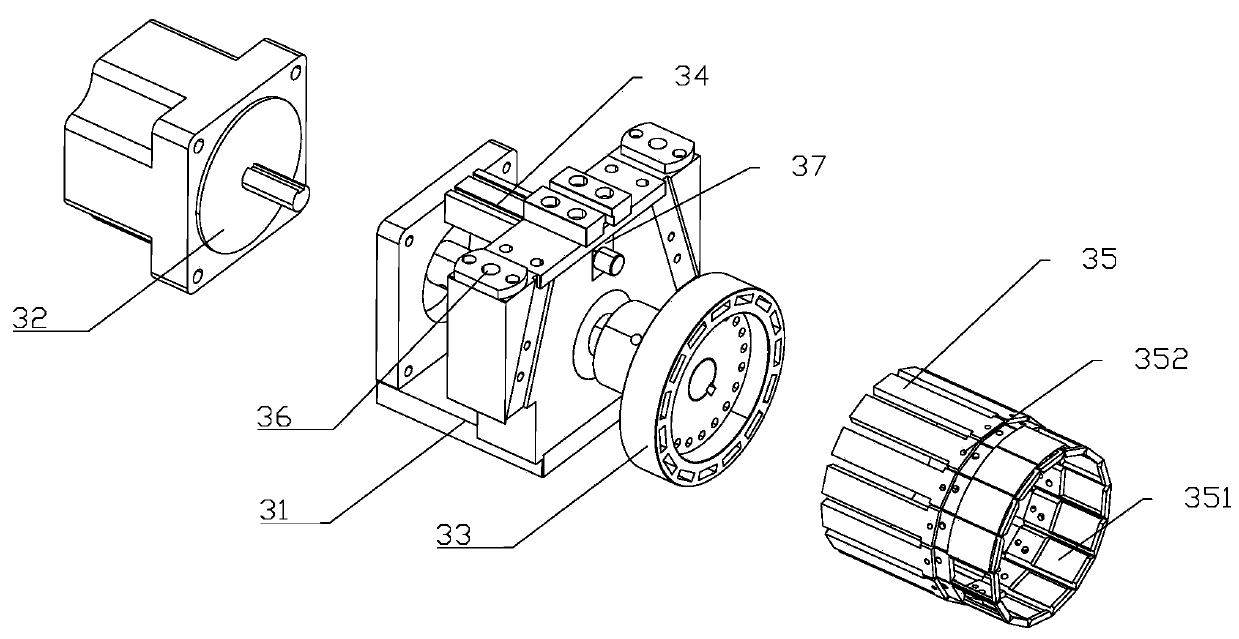

[0023] like figure 1 and figure 2 As shown, a cable end gluing device includes a frame 1, a base assembly 2, a reel assembly 3, a film feeding assembly 4, a cutting assembly 5 and a pressing assembly 6; the base assembly 2 is installed on the frame 1 , the reel assembly 3 is connected to the base assembly 2, the press assembly 6 is installed on the frame 1, and is located directly above the reel assembly 3, the cutting assembly 5 is obliquely arranged on the reel assembly 3, and the film feeding assembly 4 It is arranged on the frame 1 and is located on the side of the reel assembly 3 .

[0024] The film feeding assembly 4 is used to convey the single-sided adhesive material, the reel assembly 3 is used to wind the single-sided adhesive, and send out the cut single-sided adhesive, and the cutting assembly 5 pairs the reel assembly The single-sided tape on 3 is cut to length, and the pressing assembly 6 is used to attach the cut single-sided tape to the surface of the cable;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com