A method of using a traceability system based on differential pressure casting automation

A traceability system and differential pressure casting technology, which is applied in the field of aluminum alloy low-pressure casting, can solve the problems of untraceable product production process information and unfavorable management, and achieve the effect of convenient management and maintenance of equipment and defect analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

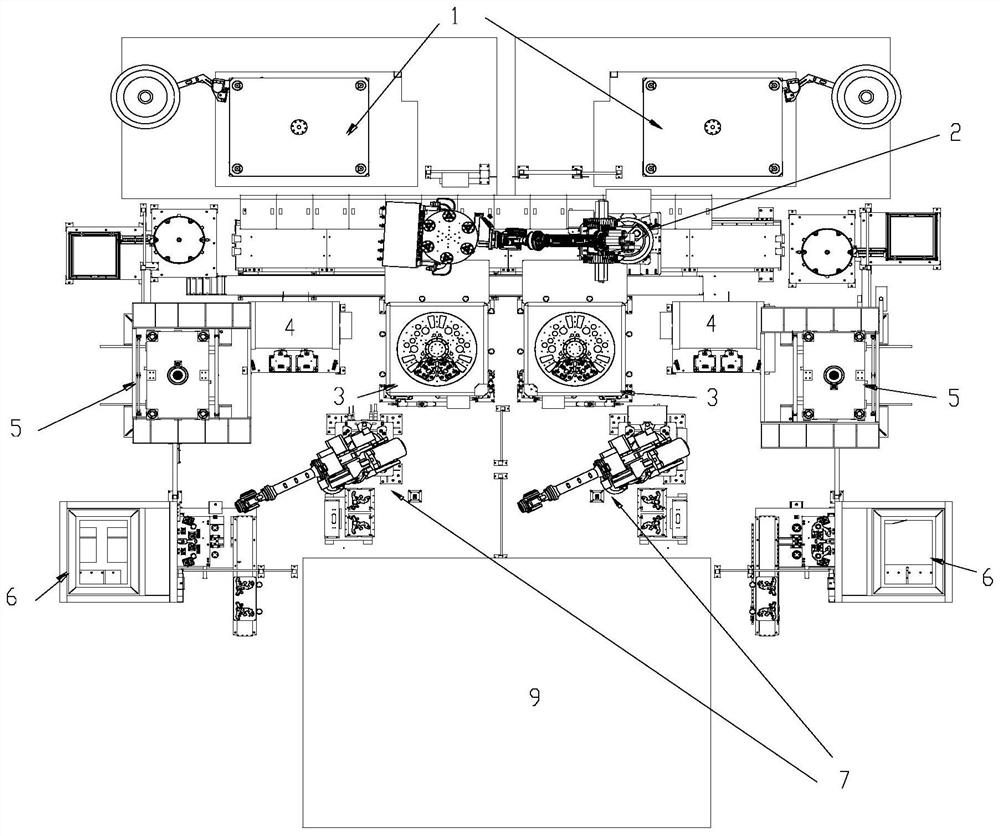

[0021] Such as figure 1 , the workpiece is cast by differential pressure casting machine 1, because the temperature of the cast workpiece is very high when it is produced, it is necessary to place the produced workpiece on the water soaking device 3 by the blanking robot 2 in the handling robot 7, and the water soaking device 3. It is internally connected to the circulating cooling water system of the factory, and its function is to rapidly cool the cast workpiece. The robot will send a signal to the robot when it is unloading. At this time, the main control PLC records the unloading time of this batch of workpieces. When the workpieces are placed in the water soaking device, the main control PLC records the time when the workpieces are placed in the water soaking device. The role of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com