Precision cutting device and splitting method for test sheet

A precision cutting and test piece technology, applied in metal processing, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of increasing the difficulty of section analysis, unsuitable cutting distance, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

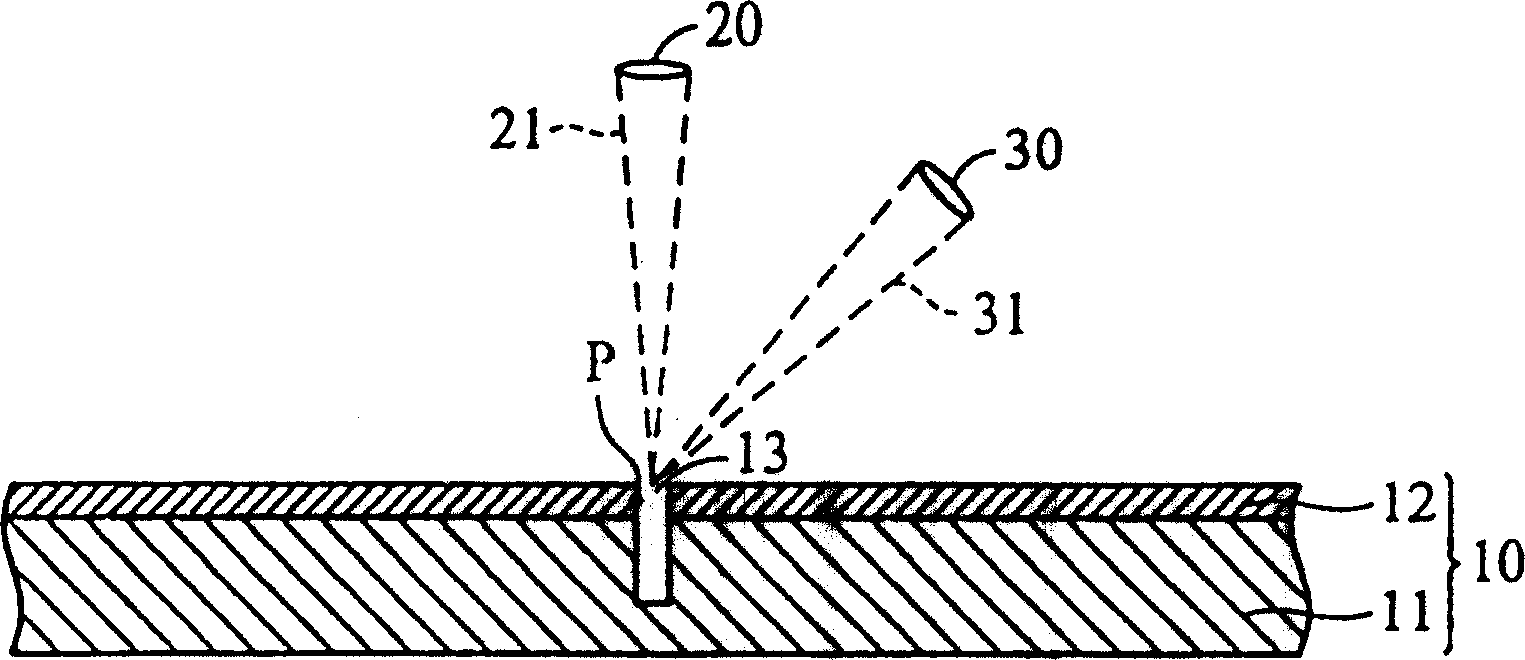

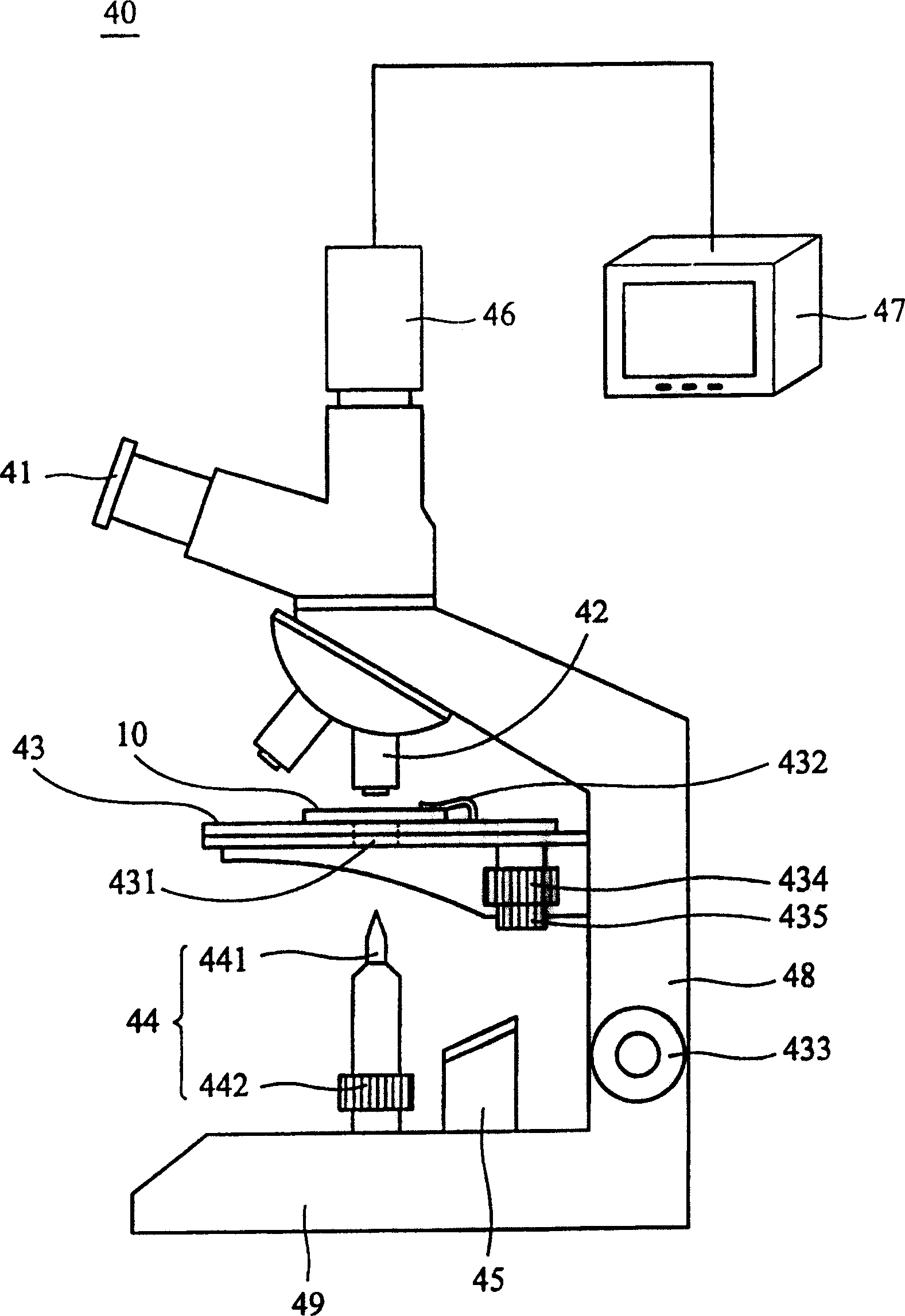

[0023] figure 2 It is a side view of the precision cutting device of the test piece of the present invention. Such as figure 2 As shown, the precision cutting device 40 of the present invention includes a microscope and a cutting tool group 44 that can be vertically telescopic and movable; wherein the optical microscope used in the present invention has a carrying platform 43 that can carry the test piece 10, an adjustable magnification lens group and a bottom light source 45. The carrying platform 43 carrying the test piece 10 is arranged on the support arm 48 of the optical microscope, and the vertical position of the carrying platform 43 can be adjusted by the platform vertical adjustment wheel 433 . The lens group includes an eyepiece 41 and an objective lens 42 , and different magnifications can be selected by adjusting different objective lenses 42 to display the microstructure of the test piece 10 . A bottom light source 45 is arranged on the base 49 below the carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com