Lead screw counter-pulling sliding table module

A lead screw and slide table technology, applied in the field of lead screw to pull slide table module, can solve the problems of loss of positioning accuracy, impact on the service life of the lead screw, and influence on the positioning accuracy of the moving block, so as to improve the service life and solve the problem of the lead screw Jitter, the effect of solving the loss of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

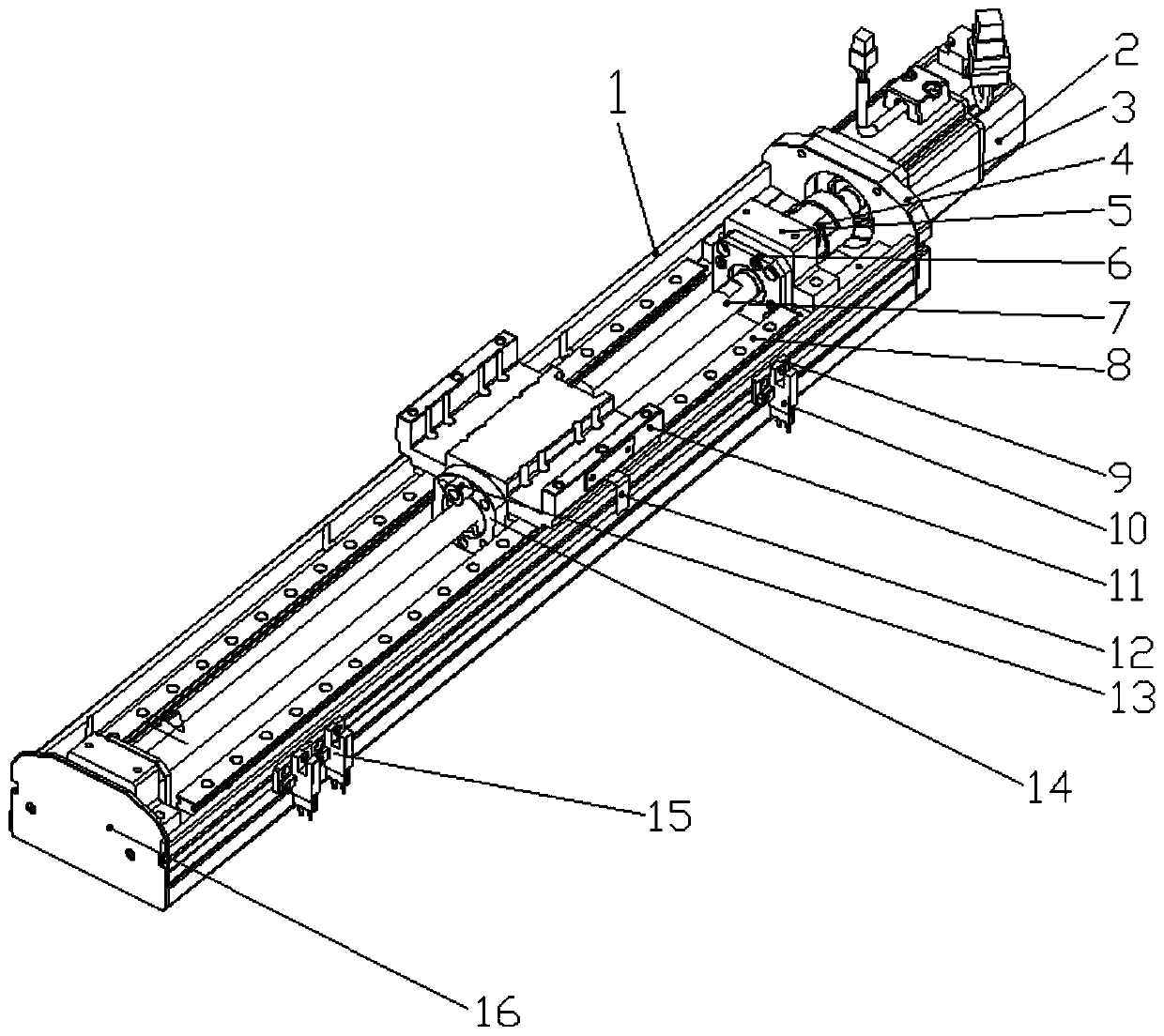

[0012] In order to realize the technical means of the present invention, the present invention will be further described below in conjunction with specific illustrations.

[0013] Such as figure 1 As shown, a screw pull slide module of the present invention includes a base 1, a servo motor 2, a coupling 4, a slide rail 8, a moving plate 11, and a ball screw, and a motor is fixed at one end of the base 1 The mounting plate 3 has an end cover plate 16 at the other end, and two slide rails 8 parallel to each other are arranged on the base 1 between the motor mounting plate 3 and the end cover plate 16, and ball wires are arranged between the two slide rails 8. The nut 14 of the ball screw is fixed with a moving plate 11, and the moving plate 11 slides on the slide rail 8. The two ends of the screw 7 of the ball screw are installed on the screw bearing support seat 6, and one end of the screw 7 Through the screw bearing support base 6 and connected with the output shaft of the se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap