Constant-humidity machine water tank for showcase

A technology of constant humidity machine and water tank, which is applied in the direction of water saving, display cabinets, applications, etc. It can solve the problems of fixed structure, water addition, and affecting the use efficiency of instruments, so as to achieve the effect of increasing efficiency and increasing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

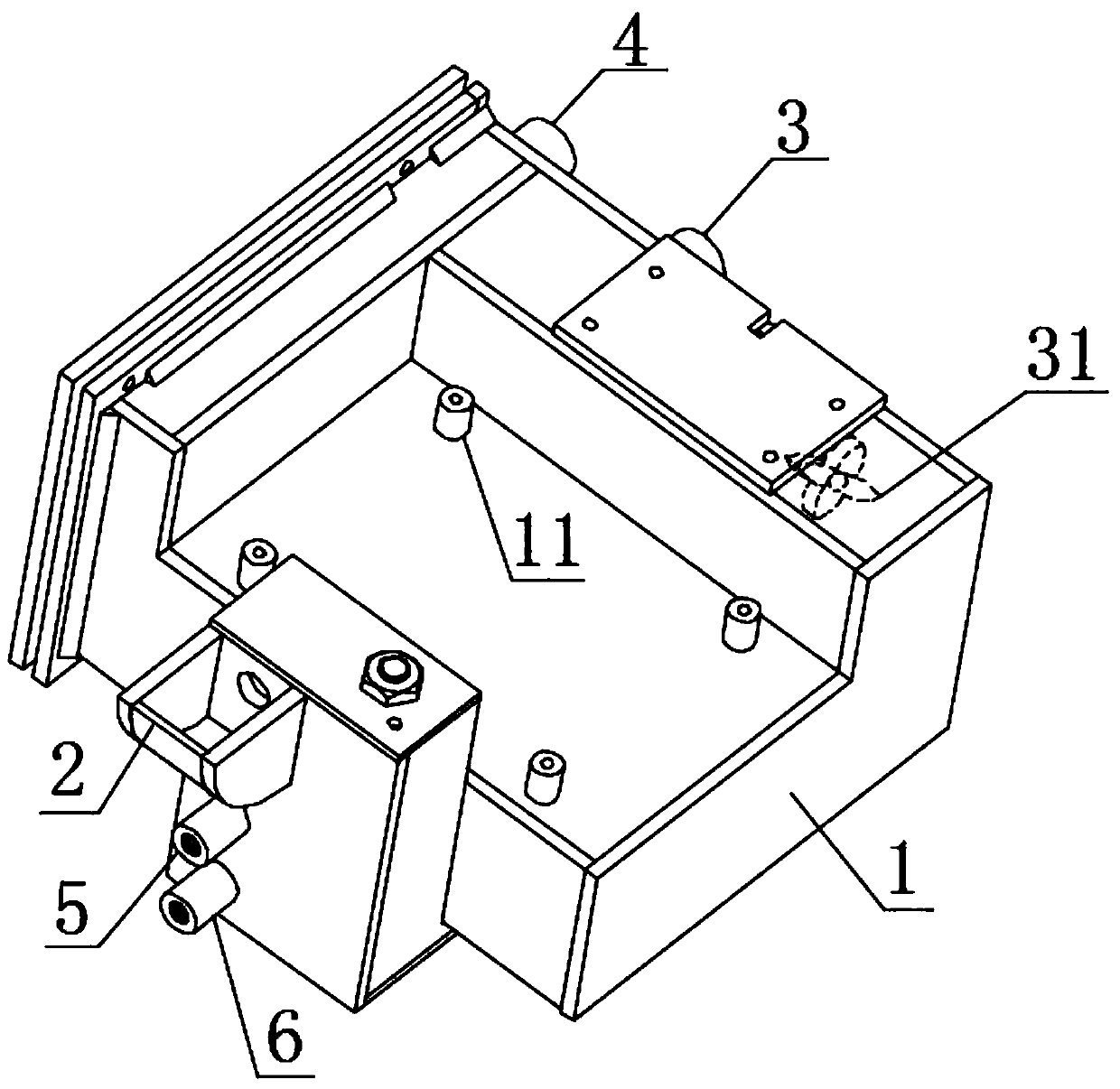

[0036] A water tank for a constant humidity machine for a display cabinet, comprising a water storage tank, the water storage tank includes a main box body 1, a water inlet 2, an air inlet pipe 3, an air outlet pipe 4, an overflow port 5 and a water discharge port 6, and the main box body 1 The top surface is provided with a main board fixing column 11 and a liquid level control switch. Both the air inlet pipe 3 and the air outlet pipe 4 are fixedly connected to the main box body 1. The inlet of the air inlet pipe 3 is provided with a fan 31, and the air outlet pipe 4 is connected to the display cabinet. The body is connected, and the drain port 6 is equipped with a suction pipe.

[0037] The water storage tank is assembled inside the ZB-HC-004 micro-environment intelligent constant humidity machine to store water. Add water from the water inlet 2 to the main box body 1, start the constant humidity machine, and under the action of the fan 31, the display cabinet body The air e...

Embodiment 2

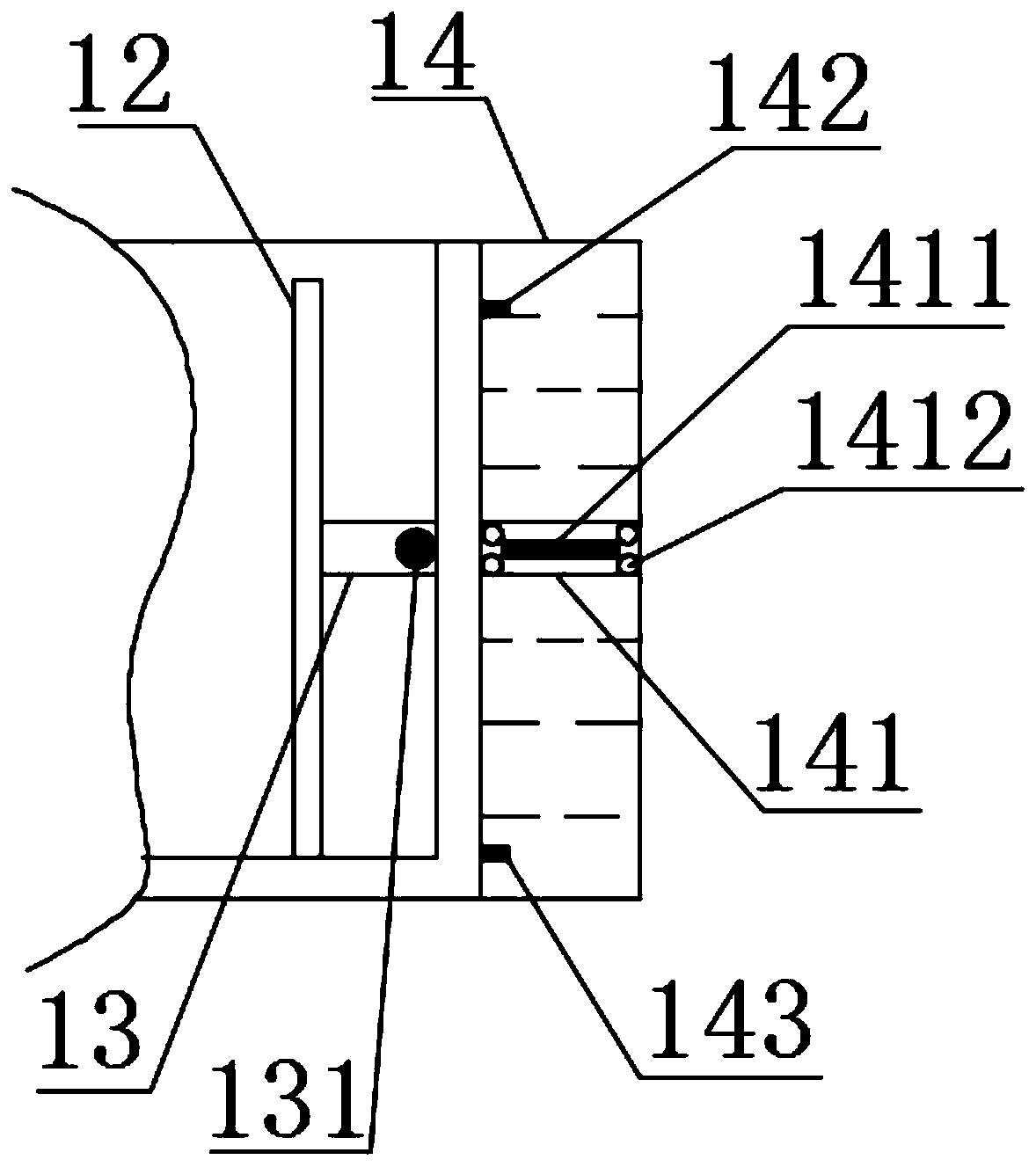

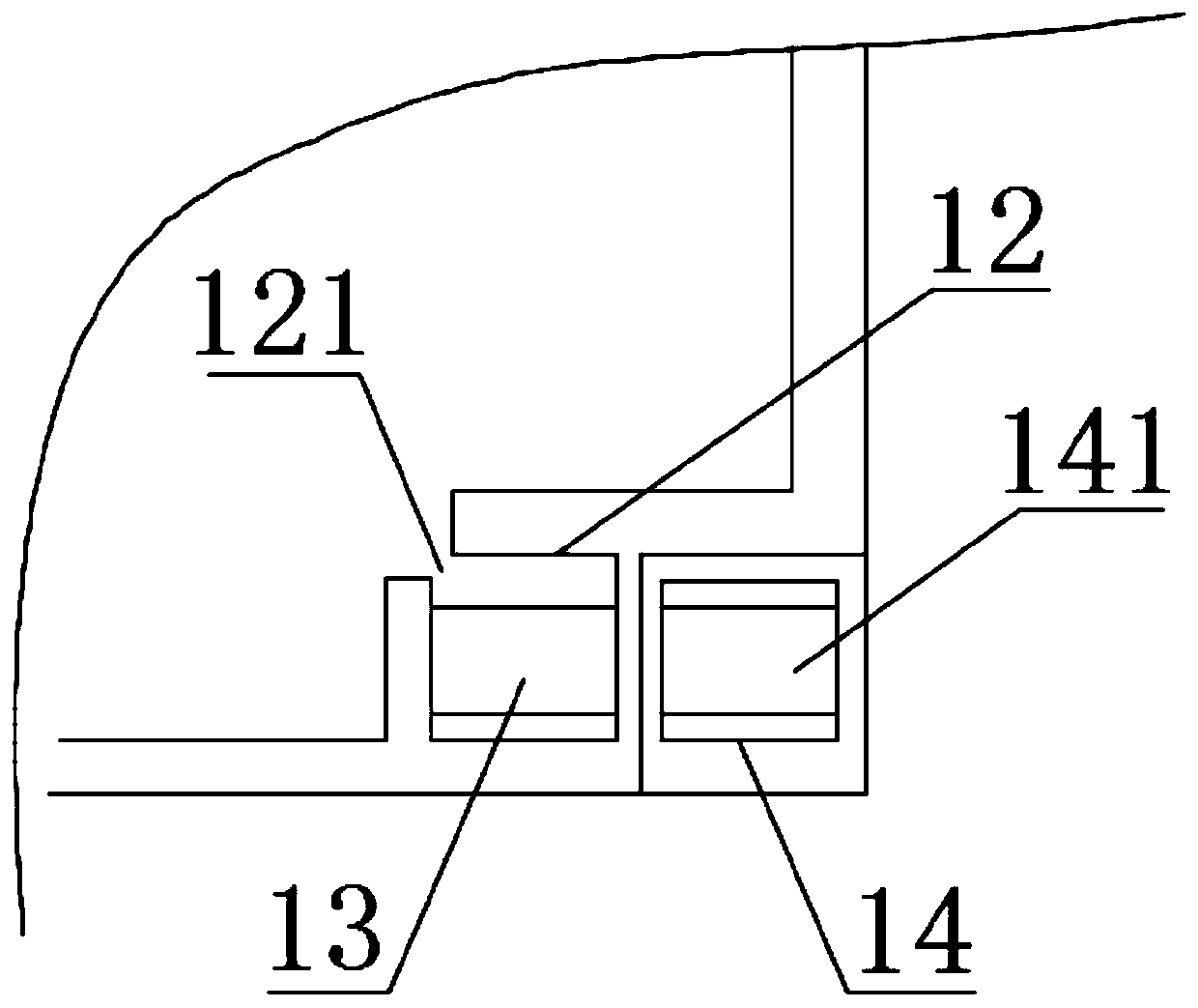

[0039] A water tank for a constant humidity machine for a display cabinet, comprising a water storage tank, the water storage tank includes a main box body 1, a water inlet 2, an air inlet pipe 3, an air outlet pipe 4, an overflow port 5 and a water discharge port 6, and the main box body 1 The top surface is provided with a main board fixing column 11 and a liquid level control switch. The liquid level control switch includes a monitoring tank 12, an inner floating plate 13 and a monitoring cylinder 14. The monitoring tank 12 is provided with a side channel 121, and the inner floating plate 13 is inlaid with a permanent magnet. Ring 131, monitoring tube 14 includes filling liquid, outer floating plate 141, upper pressure sensor 142, lower pressure sensor 143, alarm 144 and alarm power supply 145, outer floating plate 141 is provided with soft magnetic sheet 1411 and ball 1412, upper pressure The sensor 142 and the down pressure sensor 143 are electrically connected with the al...

Embodiment 3

[0042] A water tank for a constant humidity machine for a display cabinet, comprising a water storage tank, the water storage tank includes a main box body 1, a water inlet 2, an air inlet pipe 3, an air outlet pipe 4, an overflow port 5 and a water discharge port 6, and the main box body 1 The top surface is provided with a main board fixing column 11, a liquid level control switch, a long baffle 15 and a short baffle 16, and the water inlet 2 includes a water inlet pipe 21, a ceramic filter element 22 and a water inlet cover 23, and the ceramic filter element 22 is screwed to the water inlet pipe 21 , one end of the water inlet cover 23 is rotationally connected with the water inlet pipe 21, the other end of the water inlet cover 23 is magnetically attracted to the water inlet pipe 21, the air inlet pipe 3 and the air outlet pipe 4 are fixedly connected with the main box body 1, and the air inlet pipe The entrance of 3 is provided with a fan 31, the air outlet pipe 4 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com