A shield machine inner and outer double-layer main drive system

A technology of inner and outer double-layer shield machines, which is applied in mining equipment, tunnels, earthwork drilling and mining, etc., and can solve the problem that the main drive system cannot fully adapt to the parameter requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

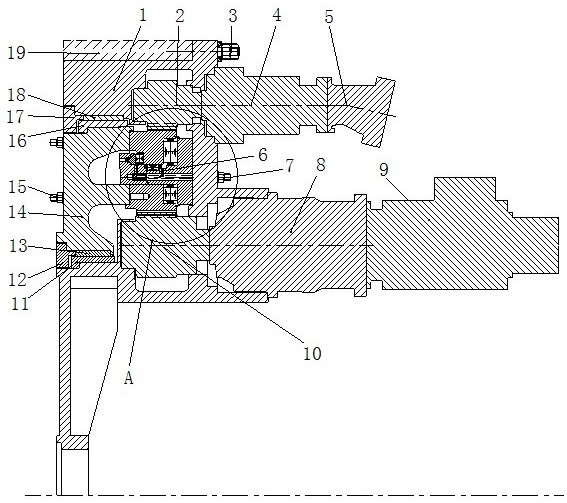

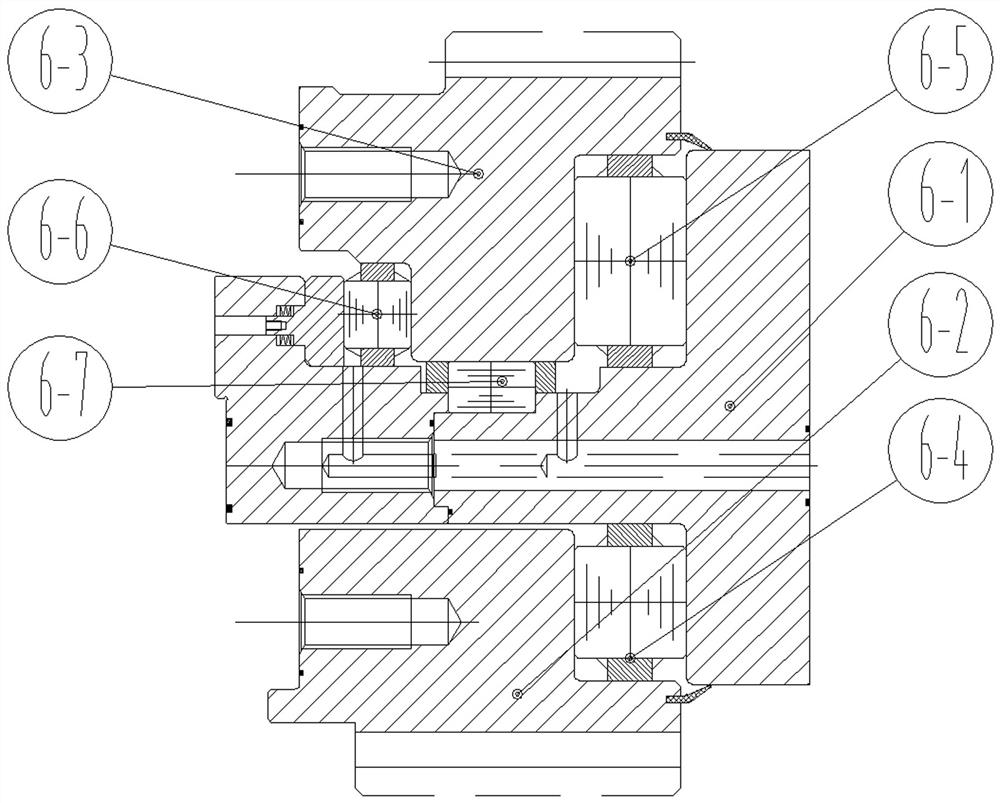

[0025] Embodiment 1, a double-layer main drive system inside and outside a shield machine, such as figure 1 As shown, it includes a drive box 1 connected to the shield body 19 through a first fastener 3 , a drive mechanism is arranged inside the drive box 1 , and a drive disc 14 is provided at the end of the drive box 1 in transmission connection with the drive mechanism. Described driving mechanism comprises inner layer driving mechanism and outer layer driving mechanism, and inner layer driving mechanism and outer layer driving mechanism work independently, and both can drive drive disc 14 to rotate, and inner layer driving mechanism and outer layer driving mechanism can also work jointly.

[0026] The drive end of the inner layer drive mechanism is connected with the internal drive transmission shaft 10, the drive end of the outer layer drive mechanism is connected with the external drive transmission shaft 2, the two ends of the internal drive transmission shaft 10 and the ...

Embodiment 2

[0031] Embodiment 2, an inner and outer double-layer main drive system of a shield machine, the inner layer driving mechanism and the outer layer driving mechanism both include a hydraulic motor and a hydraulic drive reducer, and the hydraulic motor of the inner layer drive mechanism is driven by a hydraulic drive reducer The internal drive transmission shaft 10, the hydraulic motor of the outer drive mechanism drives the external drive transmission shaft 2 through the hydraulic drive reducer.

[0032]Both the inner drive mechanism and the outer drive mechanism are driven by variable frequency motors, which is not only convenient for manufacturing and installation, but also convenient for unified control. When the inner drive mechanism and the outer drive mechanism need to work together, it is only necessary to control the hydraulic reducer to output the same torque to drive the drive disc 14 to rotate synchronously; when the inner drive mechanism or the outer drive mechanism n...

Embodiment 3

[0034] Embodiment 3, an inner and outer double-layer main drive system of a shield machine, the inner drive mechanism includes a frequency conversion motor 9 and an electric drive reducer 8, and the frequency conversion motor 9 of the inner drive mechanism drives the internal drive through the electric drive reducer 8 Transmission shaft 10; the outer drive mechanism includes a hydraulic motor 5 and a hydraulic drive reducer 4, and the hydraulic motor 5 of the outer drive mechanism drives the external drive drive shaft 2 through the hydraulic drive reducer 4.

[0035] Other structures of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com