Measurement method for optical axis shaking amount of zoom camera

A measurement method and technology of a zoom camera, which are applied in the testing of machine/structural components, measurement devices, optical axis determination, etc., can solve the problems of long time consumption, high cost of measurement equipment, complicated measurement process, etc., and achieve convenient operation and simple structure. , to ensure the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

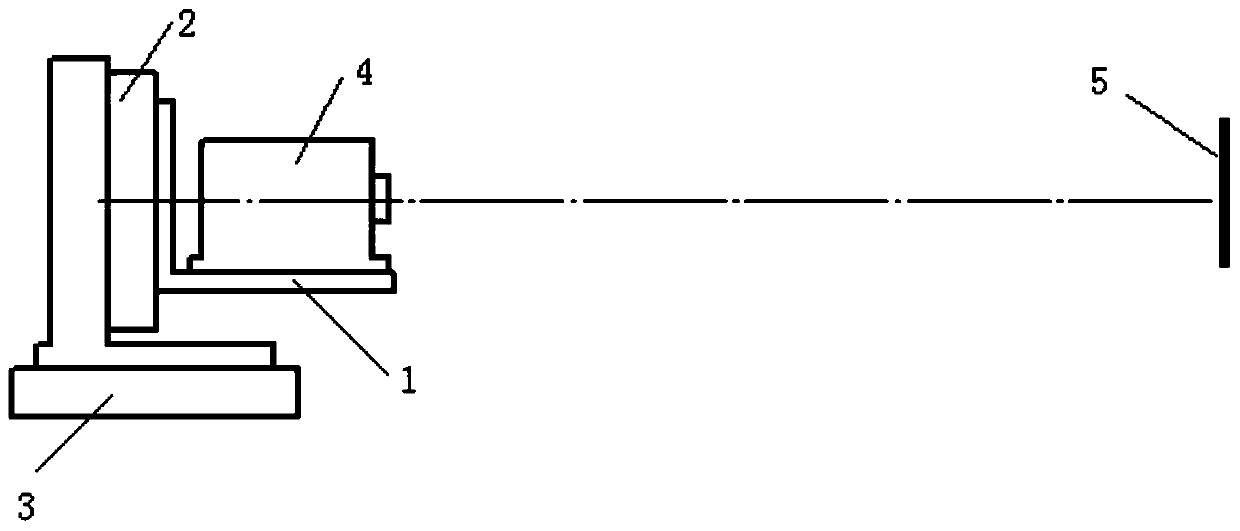

[0028] Such as figure 1 , a method for measuring the optical axis shake of a zoom camera, the specific steps are as follows:

[0029] Step 1, select the corner of the building as the target 5, fix the vertical indexing table 2 on the two-dimensional adjustment frame 3, the table top of the vertical indexing table 2 is vertical, and fix the zoom camera 4 on the vertical indexing table 2 On the camera mount 1 on the table, make the rotating shaft of the vertical indexing table 2 parallel to the optical axis of the zoom camera 4, and the parallelism is one-third of the field of view angle at the preset focal length, and then adjust the zoom camera to the preset focal length;

[0030] Step 2, adjust the optical axis of the zoom camera 4 through the two-dimensional adjustment frame 3, so that the center of the optical axis is aligned with the corner of the building, and record the first lateral miss distance x from the corner of the building to the center of the zoom camera 4 0 a...

Embodiment 2

[0035] Such as figure 1 , a method for measuring the optical axis shake of a zoom camera, the specific steps are as follows:

[0036] Step 1, select the spire as the target 5, fix the vertical indexing table 2 on the two-dimensional adjustment frame 3, the table top of the vertical indexing table 2 is vertical, and fix the zoom camera 4 on the vertical indexing table 2 On the camera mount 1 on the table, make the rotating shaft of the vertical indexing table 2 parallel to the optical axis of the zoom camera 4, and the parallelism is one-third of the angle of view to be measured, and then adjust the zoom camera to the preset focal length;

[0037] Step 2, adjust the optical axis of the zoom camera 4 through the two-dimensional adjustment frame 3, so that the center of the optical axis is aligned with the spire, and record the first lateral miss distance x from the spire to the center of the zoom camera 4 0 and the first longitudinal miss amount y 0 ;

[0038] Step 3: Rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com