Optical fiber connector

A fiber optic connector and connector technology, applied in light guides, optics, instruments, etc., can solve the problems of dust entering the connector housing and affecting the normal use of fiber optic connectors, so as to ensure the transmission efficiency of optical signals and improve dust prevention Effect, structure design simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

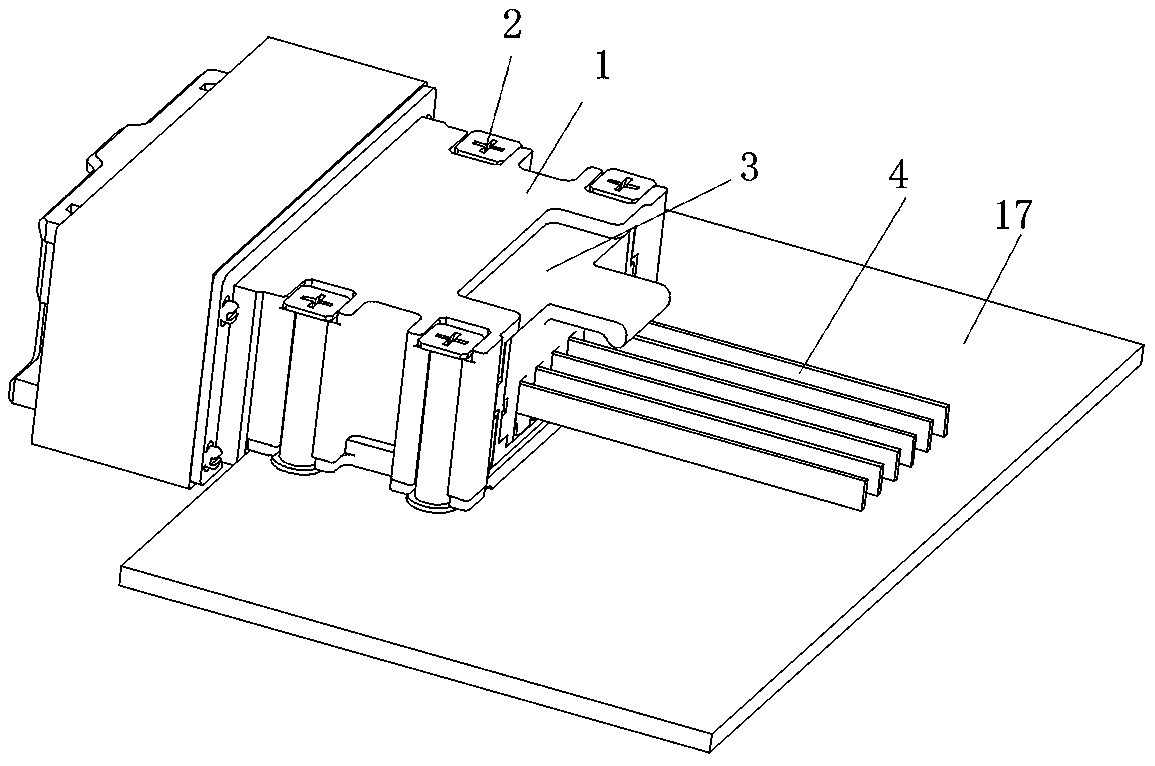

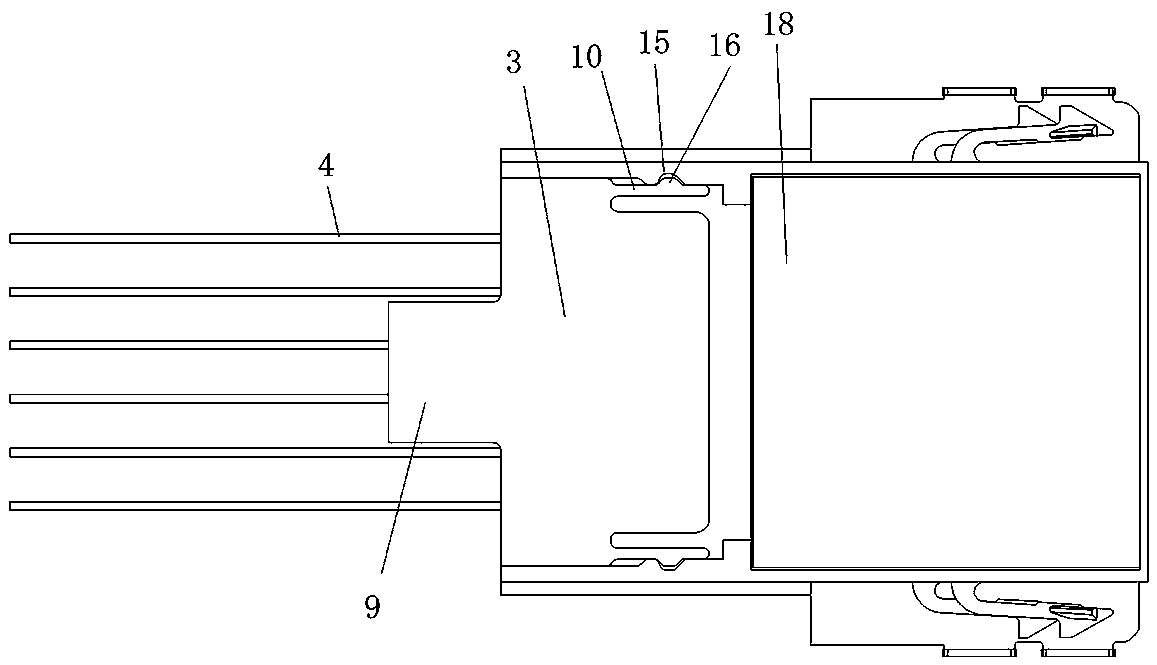

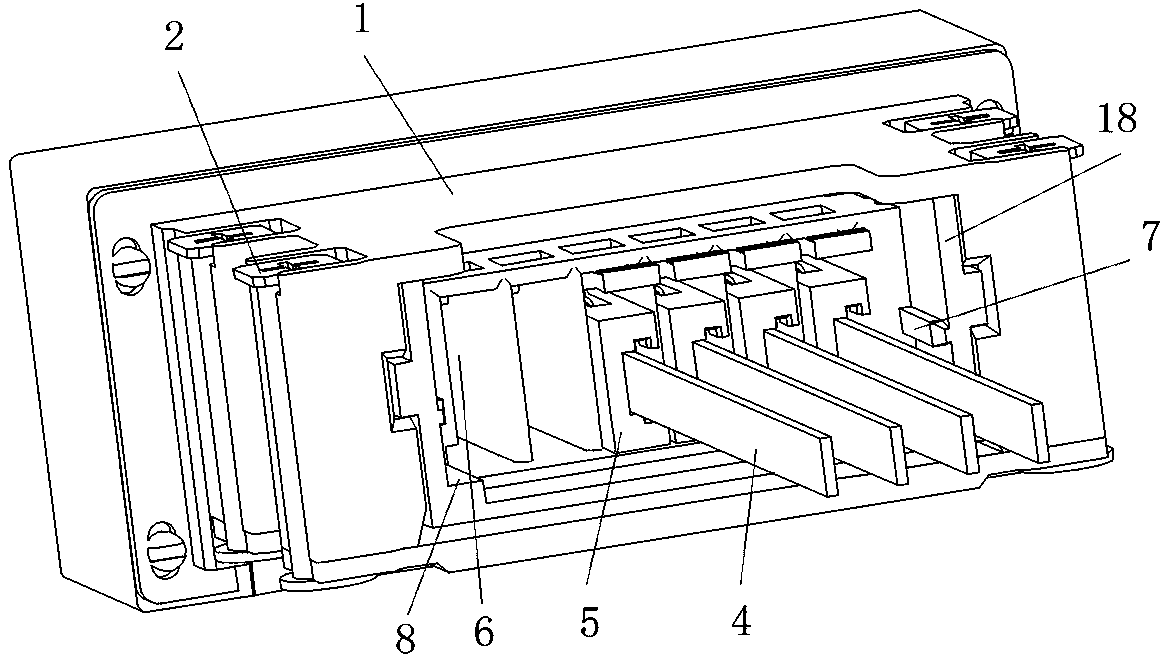

[0034] like figure 1 and figure 2 As shown, the optical fiber connector includes a connector housing, the front end of which is a plug end, and the rear end is an outlet end. The connector housing includes an outer housing 1 and an inner housing 18. The optical fiber connector is fixedly assembled on the fixing plate 17 through the cooperation of the outer casing 1 and the screw 2 . like image 3 As shown, the inner casing 18 is provided with an insertion hole 6 , and a plurality of contact modules 5 are inserted into the insertion hole 6 from the rear to the front, and the rear ends of each contact module 5 are connected with the optical cable 4 . In order to prevent dust from entering the inner casing 18 from the contact module 5 and affecting the transmission of the optical signal, the rear end of the inner casing 18 is fixedly equipped with a rear dust cover 3 .

[0035] In this embodiment, the rear dust cover 3 is snap-fitted on the inner casing 18, and the fixing met...

specific Embodiment 2

[0046] like Figure 5 As shown in the figure, the difference between this embodiment and the specific embodiment 1 is that the rear dustproof plate of the rear dust cover 3 is provided with an avoidance gap 19, and the avoidance gap 19 is not provided with dustproof teeth. The two adjacent optical cables 4 enter the inner casing 18 in the interval, and the dustproof effect is not very good.

specific Embodiment 3

[0048] The difference between this embodiment and the specific embodiment 1 is that the rear dust cover is inserted into the inner casing from top to bottom, so that the rear dust cover can be snap-fitted into the inner casing, and the upper and lower limits can be realized by snap-fitting. At this time, a guide protrusion extending in the up-down direction can be arranged on the inner wall of the inner casing, and a guide groove extending in the up-down direction can be arranged on the rear dust cover. To ensure that the rear dust cover is fixedly assembled in the inner casing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com