PLC control system of circuit breaker secondary circuit

A secondary circuit and control system technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of heavy operation and maintenance workload, low degree of control automation, cumbersome wiring, etc., to achieve reliable design principles, The effect of low operating cost and simple programming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

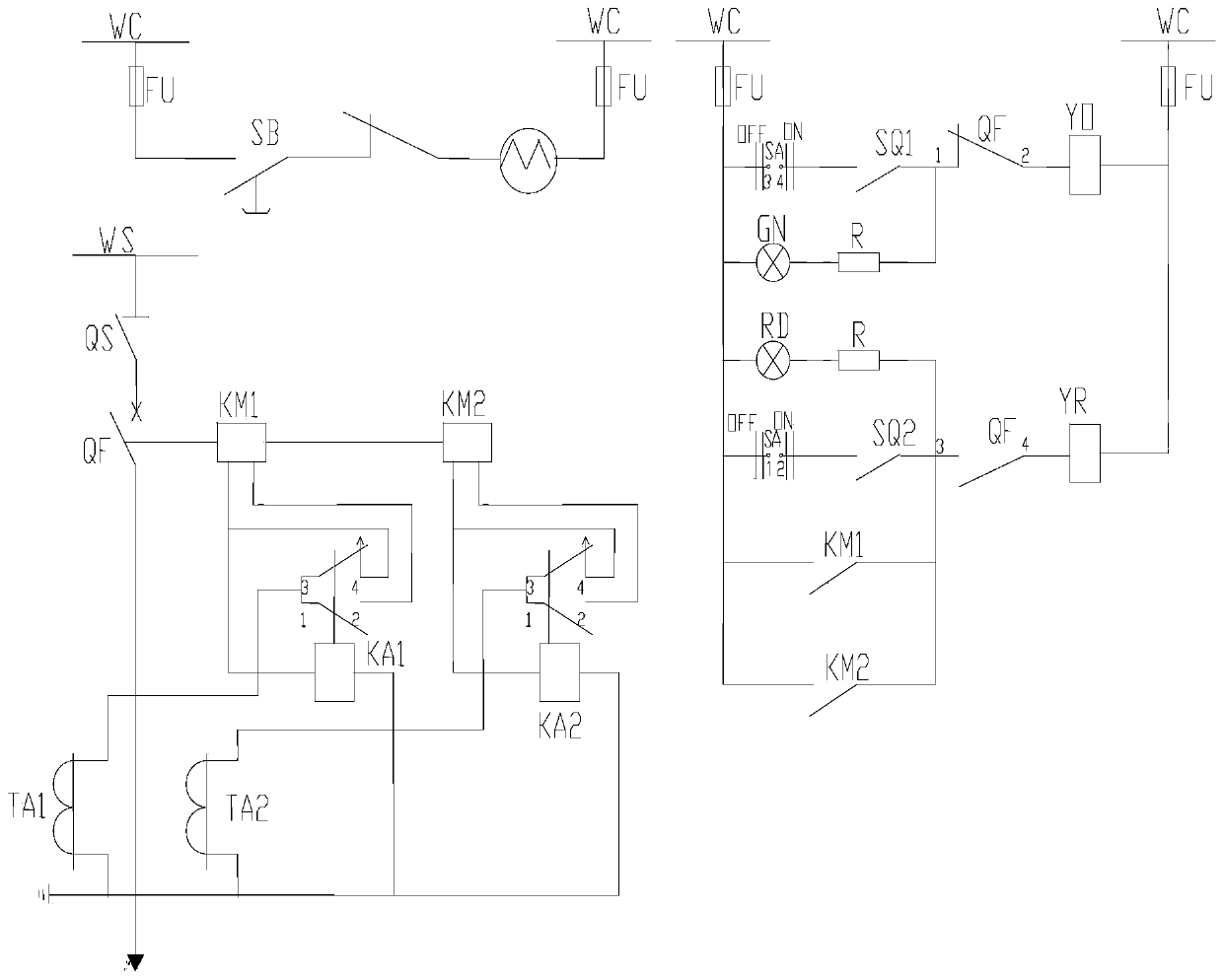

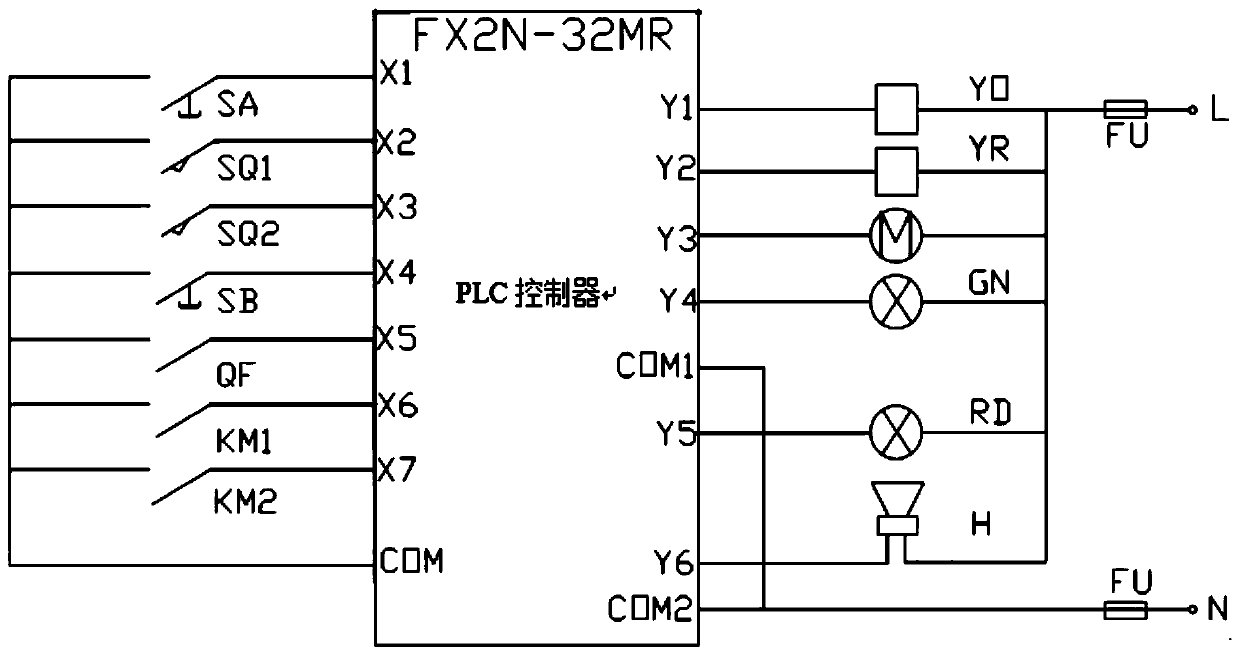

[0040] Such as figure 1 As shown, the embodiment of the present invention provides a PLC control system for the secondary circuit of a circuit breaker, including a PLC controller, a control circuit, and a detection and protection circuit; the control circuit is connected to the PLC controller through a control line;

[0041] The detection and protection circuit is connected with the PLC controller through a signal line;

[0042] One end of the control loop is electrically connected to the positive terminal of the power supply through a series fuse FU, and the other end of the control loop is connected to the negative terminal of the power supply.

[0043] The control loop includes a closing coil YO, a tripping coil YR, a circuit breaker QF, and a control switch SA;

[0044] The closing coil YO includes a first end and a second end, and the tripping coil YR includes a first end and a second end;

[0045] The first end of the closing coil YO is connected to the control switch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com