Built-in current overload protector

A technology of current overload and protector, which is applied in the direction of circuits, electric switches, electrical components, etc., to achieve precise protection and improve the effect of protection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

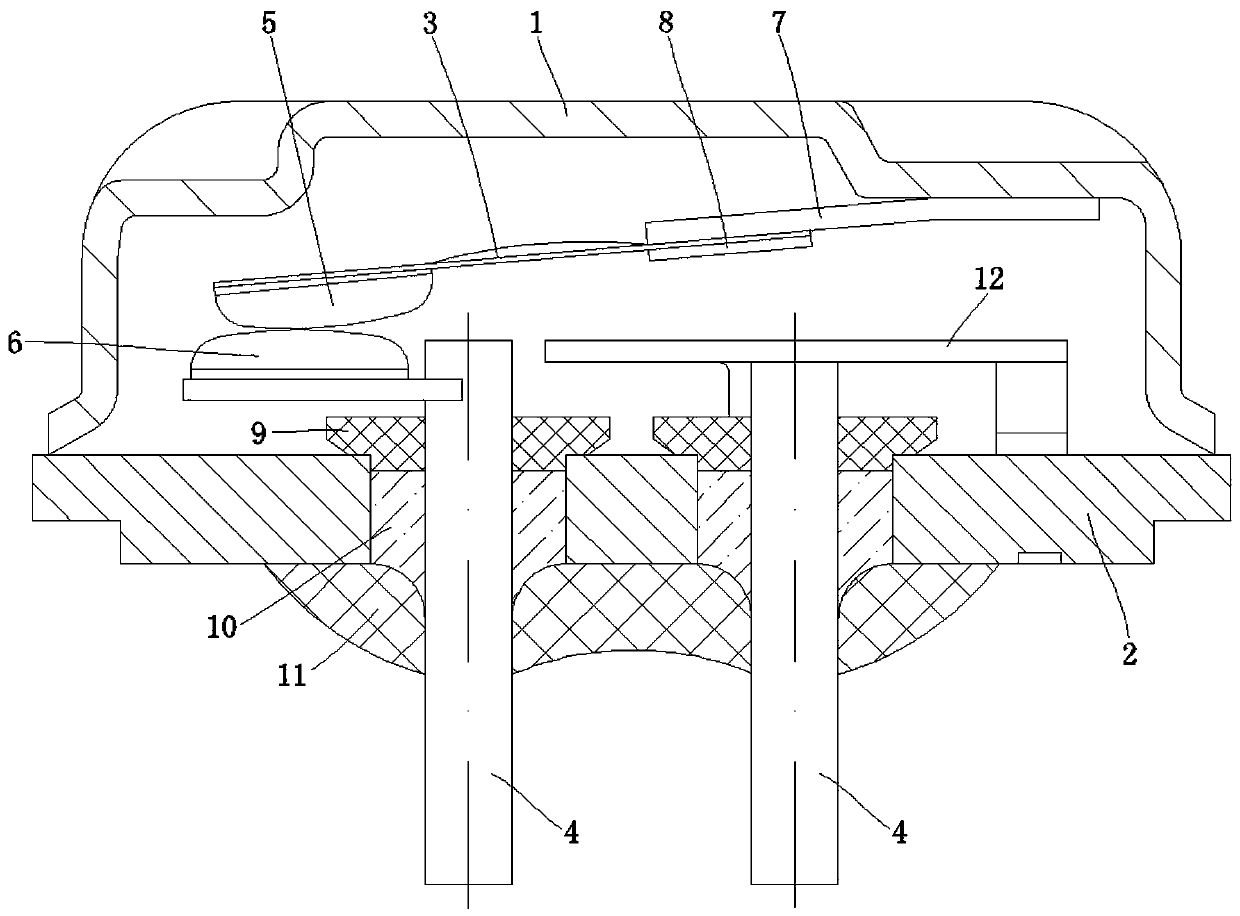

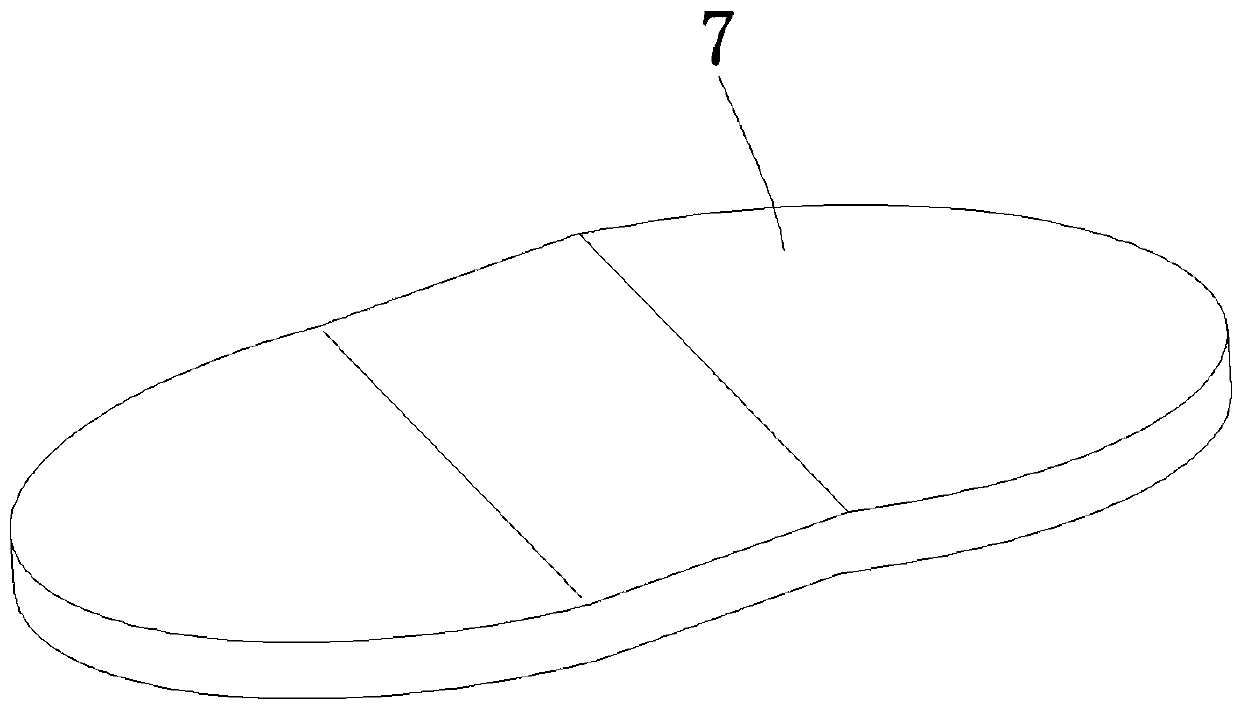

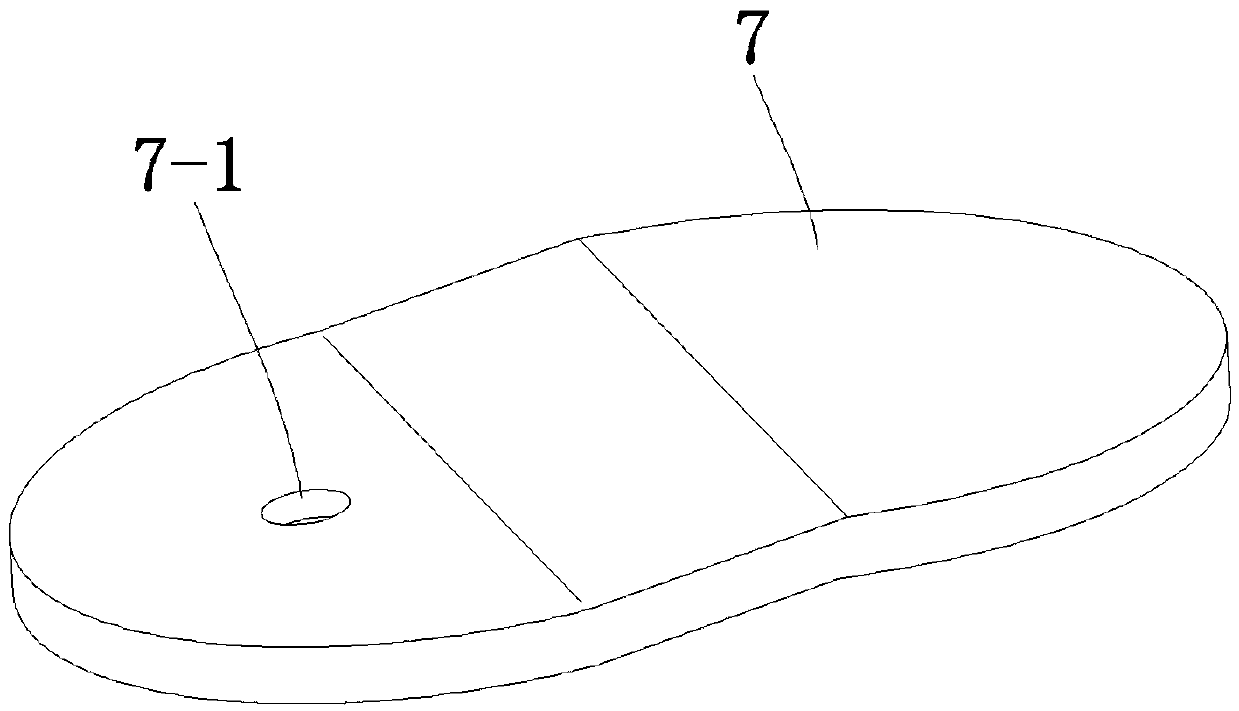

[0022] As a preferred embodiment of the present invention, the double-piece connecting piece 7 includes a sheet body made of copper alloy, iron alloy or stainless steel, the thickness of the sheet body is preferably between 0.3 and 1.5 mm, and the shape can be waist round as figure 2 , 3 As shown, it can also be a rectangle such as Figure 4 As shown, it can also be figure 8 or other shapes, which are not shown in the figure. In actual operation, according to the protection accuracy or protection level required by the electrical equipment, for example, the resistance value of the bimetal sheet must reach 120Ω, combined with the bimetal sheet grade of the protector used in the electrical equipment, such as the actual bimetal sheet grade used. The corresponding resistance value is 100Ω. Calculate the resistance difference between the resistance value corresponding to the bimetal plate grade and the required protection accuracy or protection level of the electrical equipment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com