Method for online detection of roll cooling

A detection method and roll technology, applied in the field of roll cooling, to overcome the lack of striking force and ensure safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

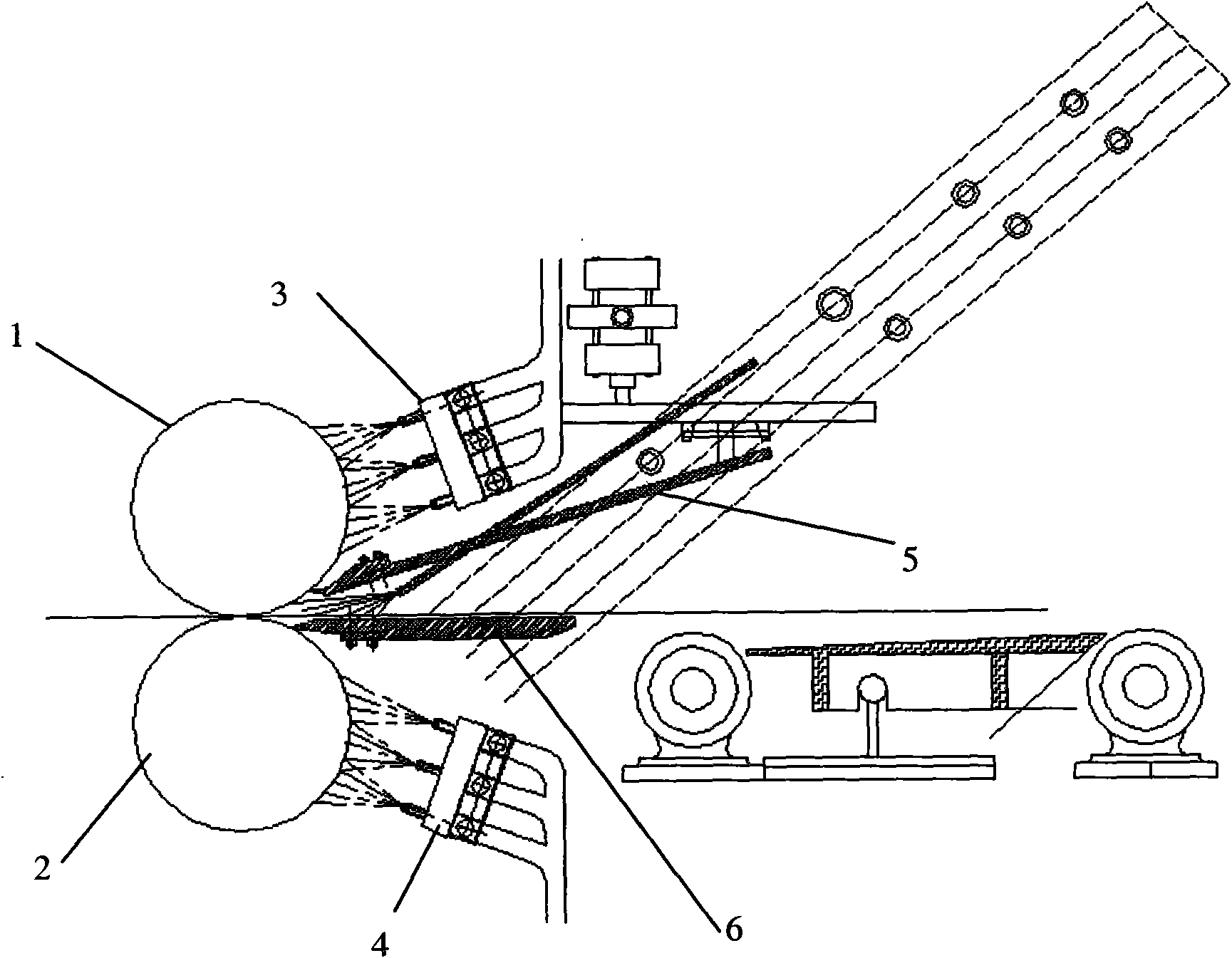

Image

Examples

Embodiment 1

[0035] 1) Roll surface coating:

[0036] The selection principle of the paint coated on the roll surface: it has sufficient adhesion, and at the same time, it can clearly retain the impact track of the roll cooling water under the impact of the 10bar roll cooling water. In this embodiment, a medium blue phenolic varnish (F03-1, standard number Q / GHTC25) is selected. This varnish has good gloss and physical and mechanical properties, and can be dried at normal temperature or at low temperature. Prepare rolls that need to be installed and checked for roll cooling water. Coat the rolls used for testing 25-45 minutes in advance and put them aside the machine for use. Ensure that the paint film is in a semi-dry state when the rolls are pushed into the rack. At an ambient temperature of 25°C, the thickness of the paint coated on the roller surface is controlled at 0.01mm to 0.05mm, and the paint is evenly applied by brushing, and the thickness of the dry film is 10 to 25μm / pass;

...

Embodiment 2

[0053] The coating is a dark blue phenolic varnish, and the coating method is spraying. The dry film thickness during spraying is 10-15 μm / pass, and the water pressure is 7bar-10bar. Others are the same as in Example 1.

Embodiment 3

[0055] The paint is dark red phenolic varnish, the dry film thickness is 15-25 μm / pass when spraying, and the water pressure is controlled at 1 bar-5 bar. Others are the same as embodiment 1.

[0056] Table 1 Judgment criteria and countermeasures for roll cooling of the present invention

[0057] state

[0058] As can be seen from the above, the online detection method for roll cooling of the present invention can accurately judge the working state of the roll cooling water, thus, problems such as wear, blockage, and deflection of the cooling water nozzle can be found in time, the production capacity of the roll is improved, and the production capacity of the roll is guaranteed. security.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com