Circuit board assembly and air conditioner

A circuit board assembly and circuit board technology, applied in the directions of printed circuit components, circuit devices, high-voltage matchers, etc., can solve problems such as safety hazards, deformation, direct contact between the copper bar surface and the control board, etc., to improve electrical insulation safety. Sexuality and the effect of ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

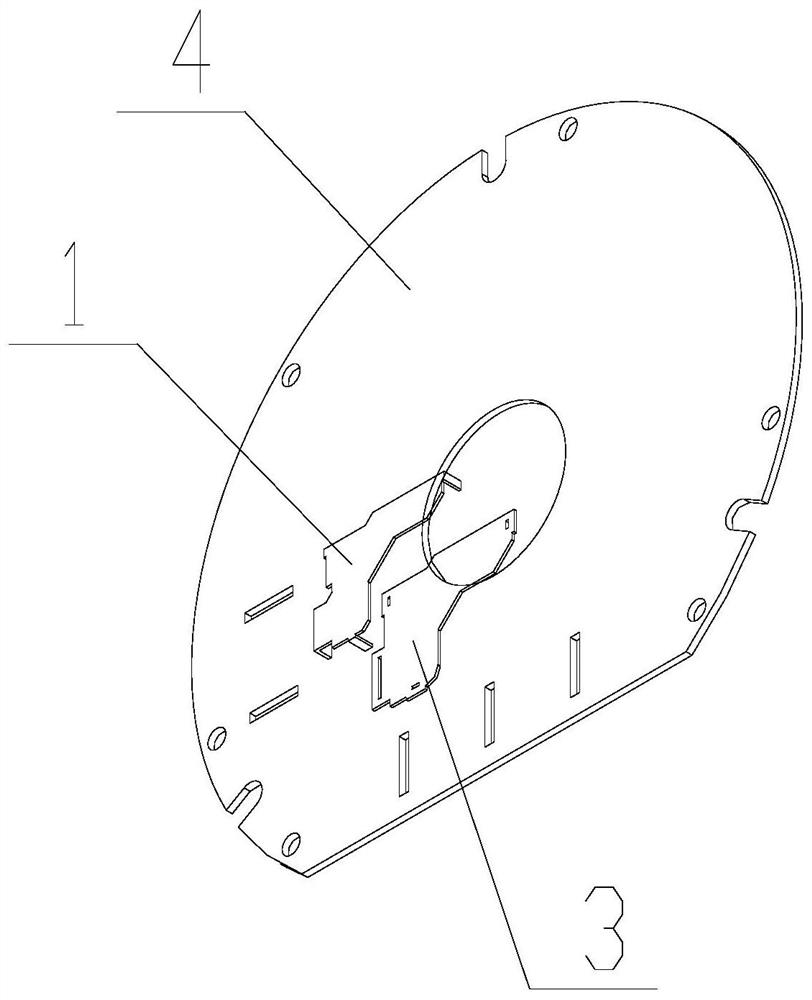

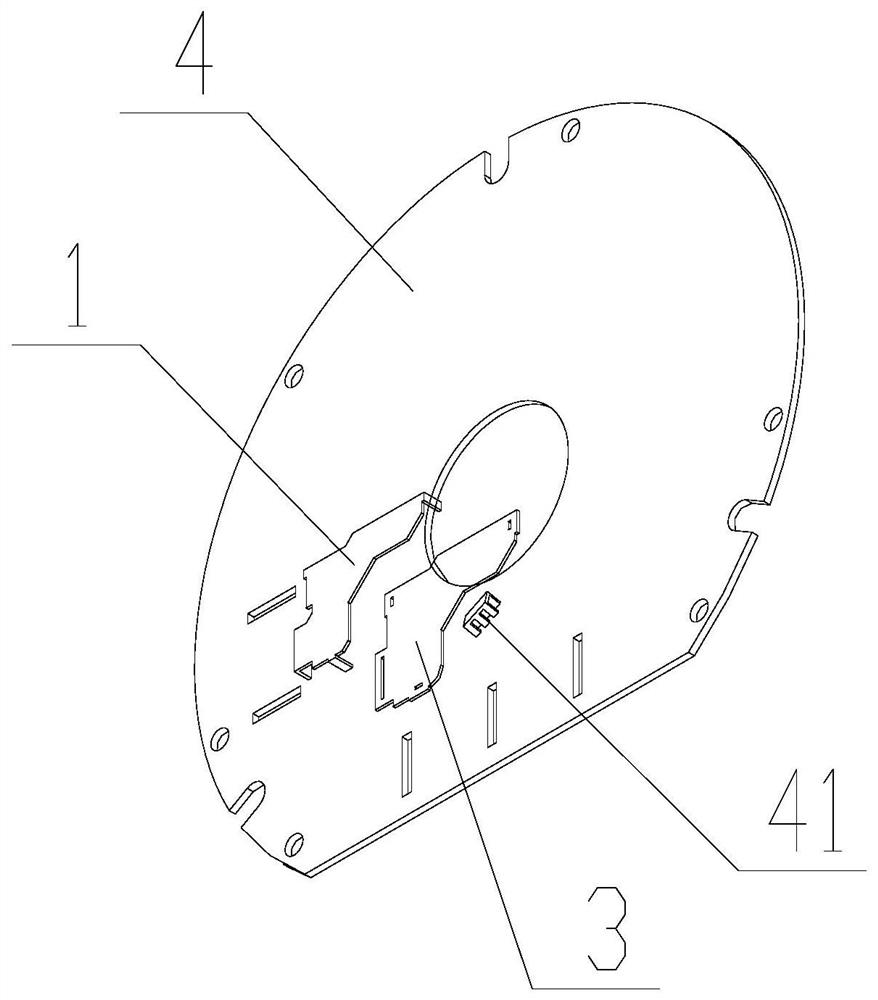

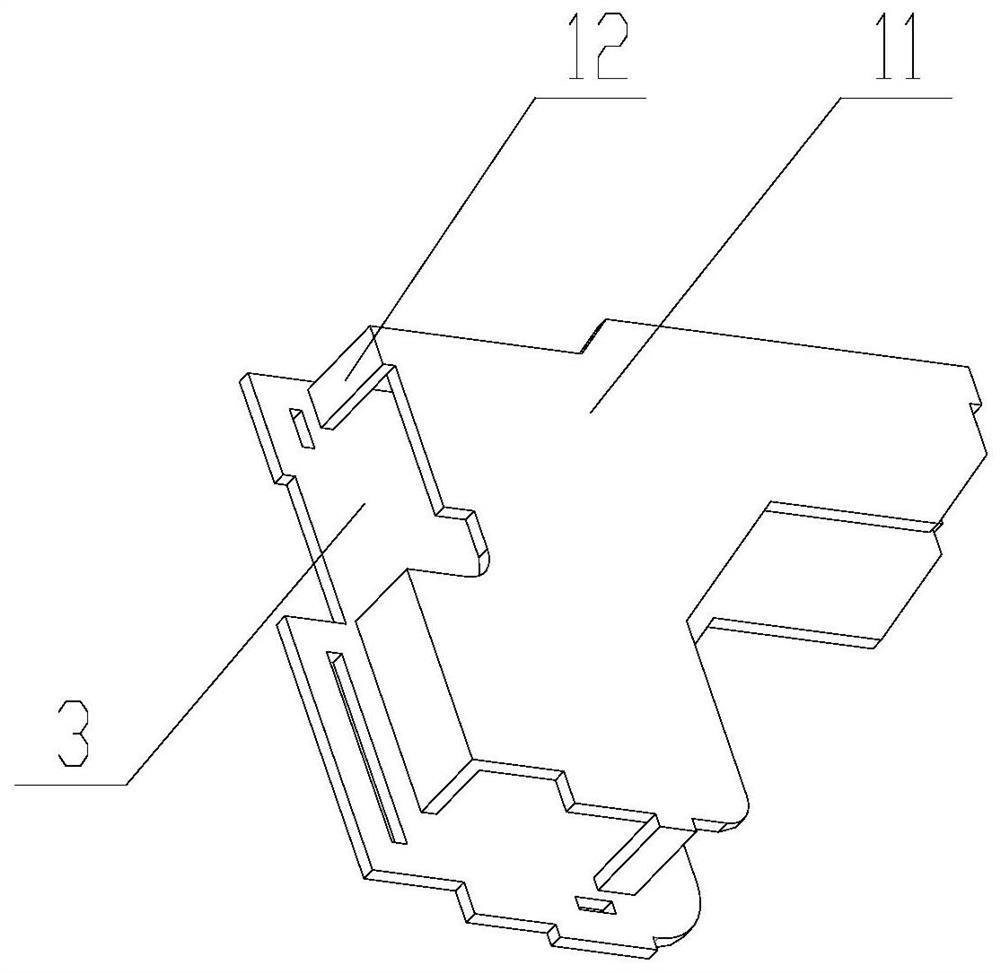

[0026] see in conjunction Figure 1 to Figure 4 As shown, according to an embodiment of the present application, a circuit board assembly includes a circuit board 4, a first conductive member 1 and a first insulating member 3, and the first conductive member 1 includes a first electrical connection section 11 and a first connection section 12 , the first electrical connection section 11 is arranged on the circuit board 4 through the first connection section 12 , and at least a part of the first insulating member 3 is arranged between the first electrical connection section 11 and the circuit board 4 . By arranging the first insulator 3 between the first connecting section 11 and the circuit board 4, the first connecting section 11 is separated from the circuit board 4, thereby ensuring a certain safety distance and preventing the first connecting section 11 from contacting the circuit board 4. The direct contact of the circuit board 4 can improve the electrical insulation safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com