Shoe washing machine

A shoe washing machine and shoe washing technology, which is applied in the field of shoe washing machines and can solve the problems of low cover assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

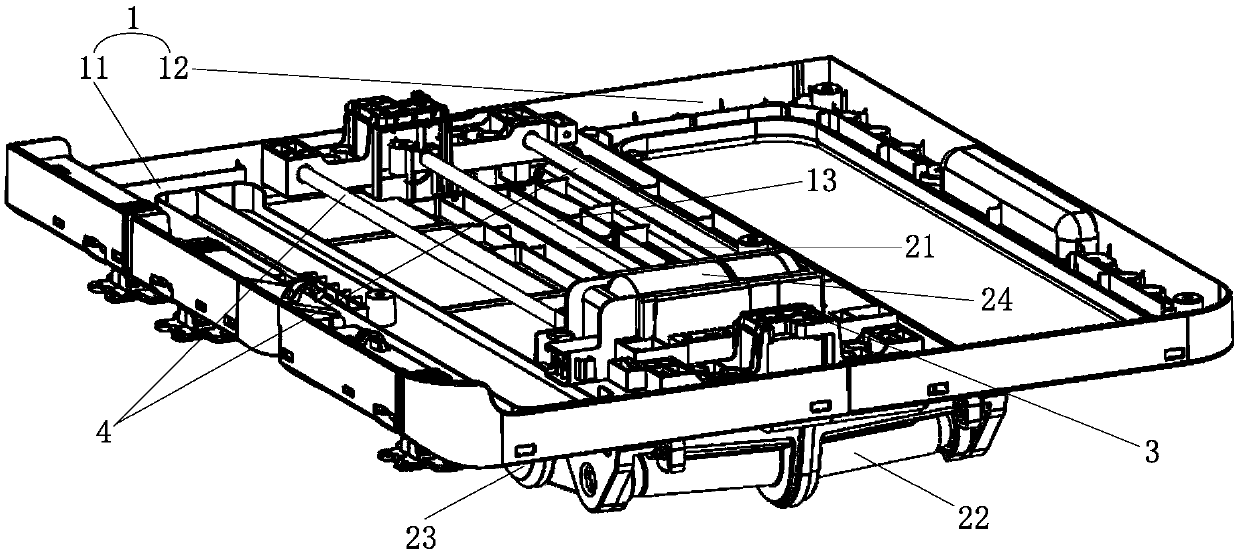

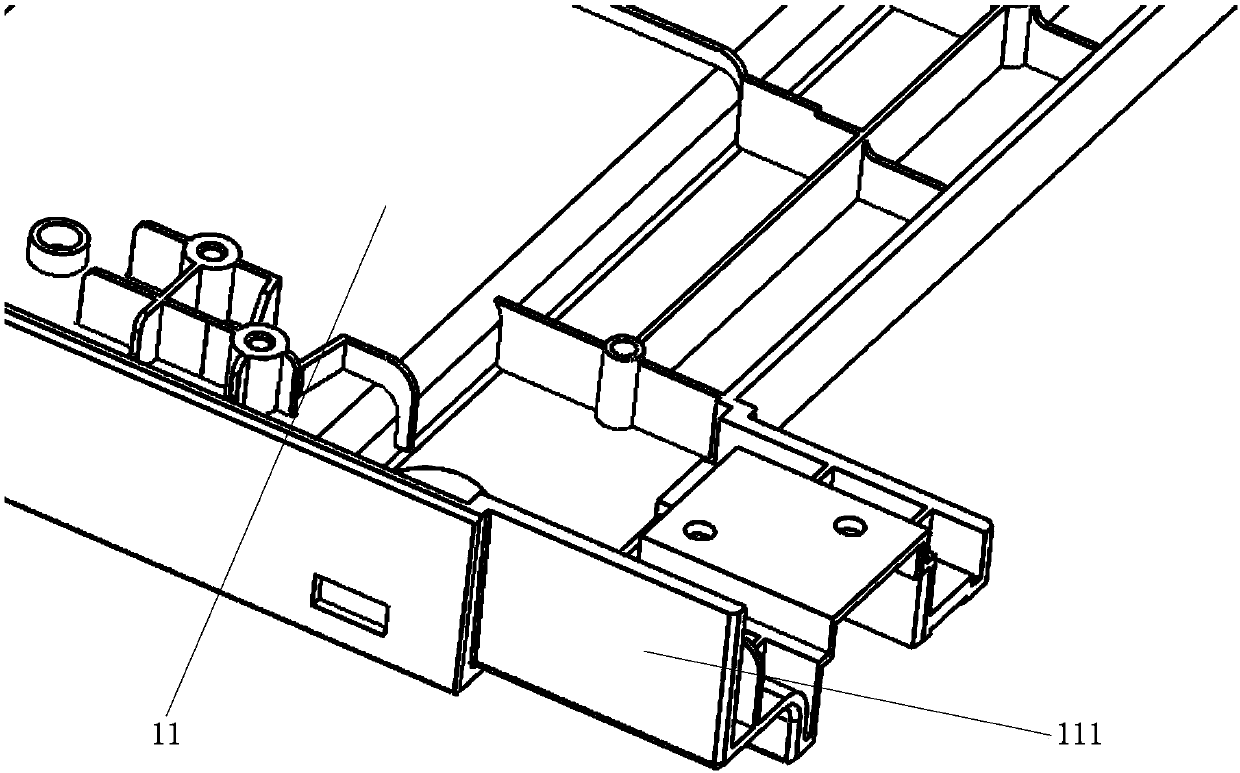

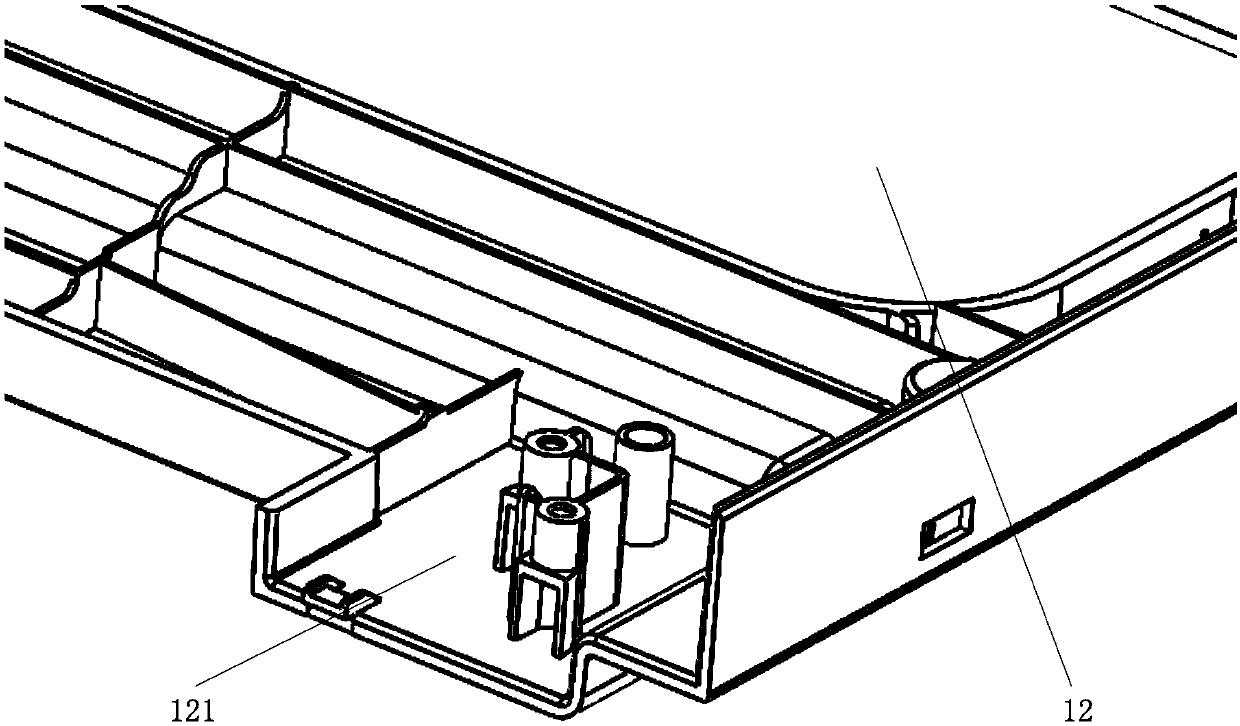

[0032] Further, the first cover 11 and the second cover 12 are formed with a sliding groove 13 at the abutting portion, the sliding member 22 can slide along the length direction of the sliding groove 13, and a part of the sliding member 22 is arranged above the sliding groove 13, sliding Another part of the member 22 is disposed below the slide groove 13 . It should be noted that although the sliding groove 13 of the present invention is formed by the butt joint parts of the first cover 11 and the second cover 12, obviously the sliding groove 13 can also be separately arranged on the first cover 11 or the second cover 11. cover 12. At the same time, in order to enhance the sealing effect of the shoe washing machine, the shoe washing machine also includes a sealing member (not shown in the figure) arranged in the sliding groove 13, and the sealing member can seal the sliding groove 13, thereby Effectively prevent the water in the box from entering the cover 1 through the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com