HDPE plastic pipe forming equipment

A technology of molding equipment and plastic pipes, which is applied in the field of pipe processing, can solve the problems of low quality of finished products and achieve the effect of ensuring the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

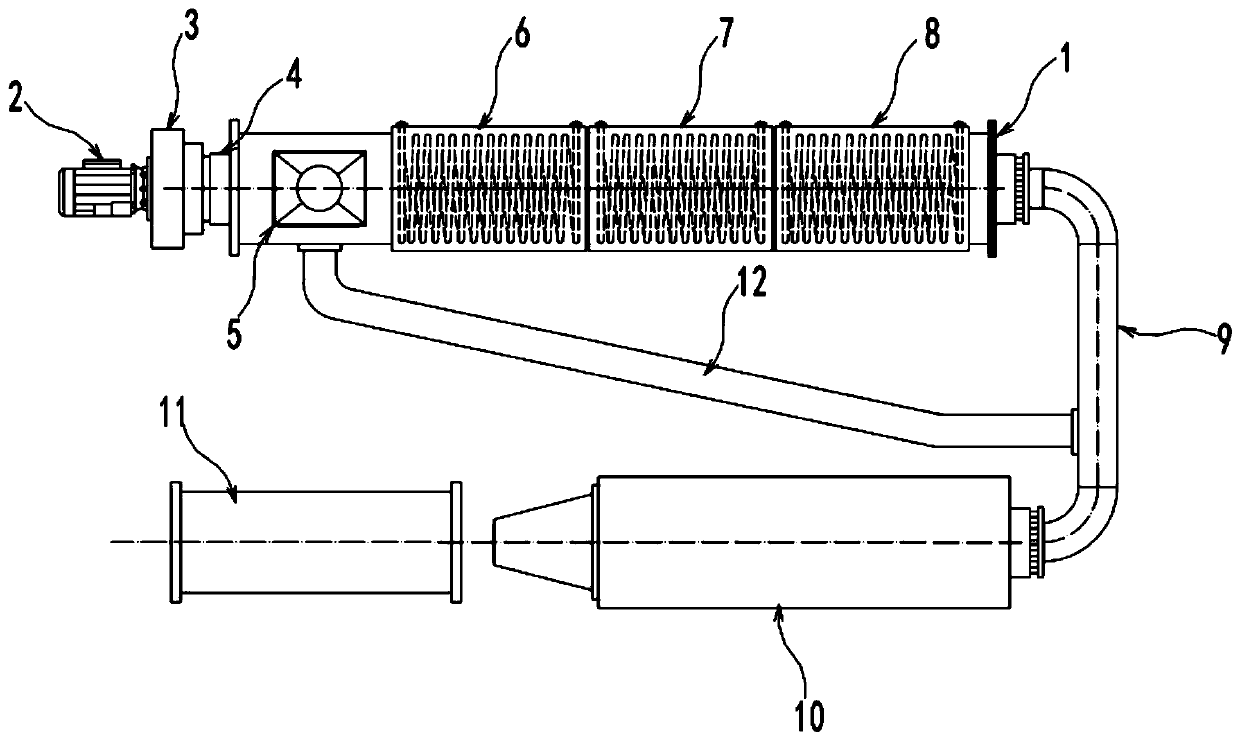

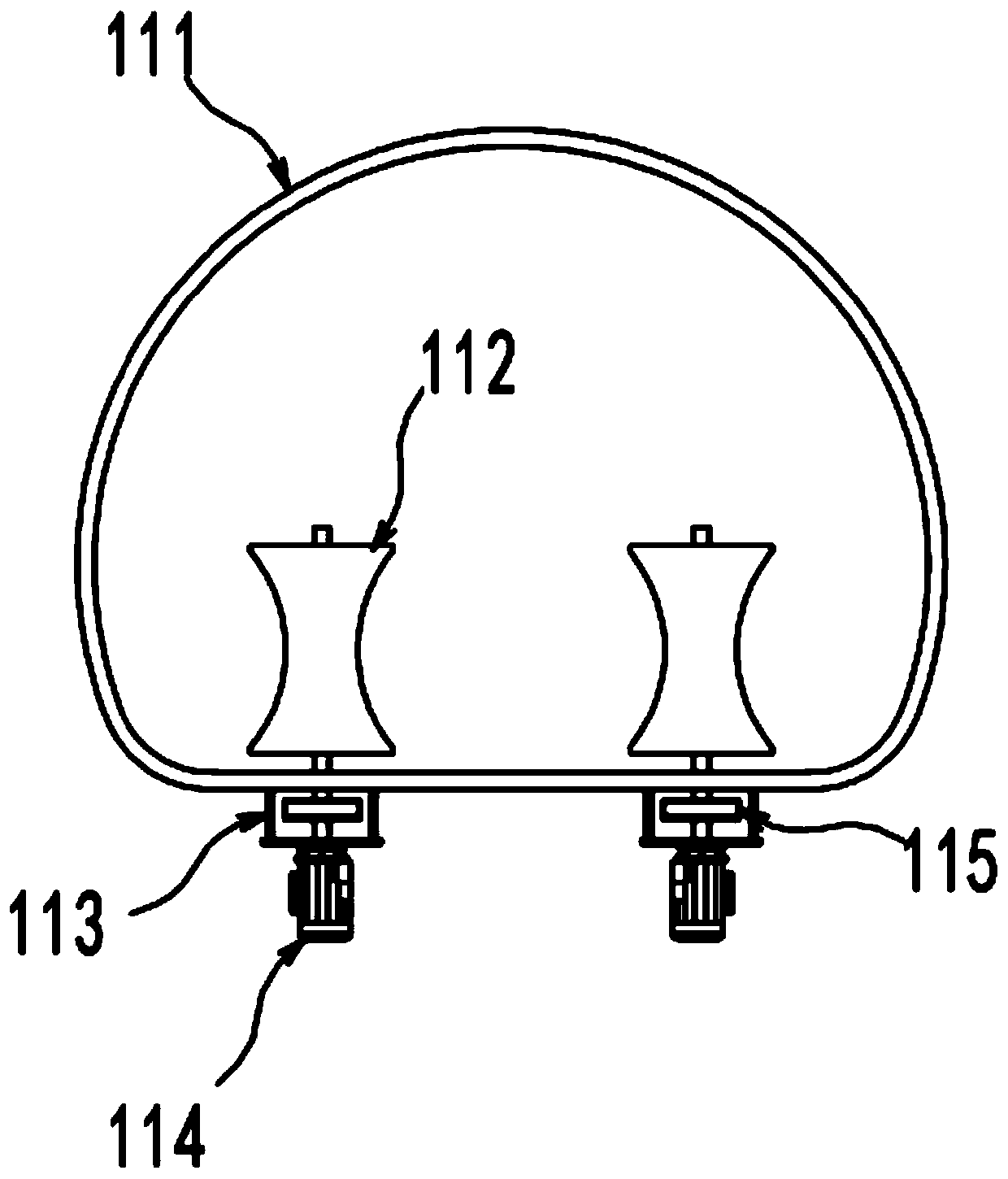

[0021] see Figure 1~2 , in the embodiment of the present invention, a HDPE plastic pipe forming equipment includes a barrel 1, a heating jacket I6, a heating jacket II7, a heating jacket III8, an extrusion die 10 and a material guide device 11,

[0022] Wherein, the barrel 1 is provided with a feeding port 5 for inputting raw materials such as HDPE powder and additives into the barrel 1, and a heating jacket I6, a heating jacket II7 and a heating jacket are installed on the outside of the barrel 1. III8, the cylinder 1 is divided into preheating section, heating section and heat preservation section, heating jacket I6, heating jacket II7 and heating jacket III8 are controlled by independent temperature control device and heat source to ensure preheating The temperature of the section, the heating section and the heat preservation section are all different. In this embodiment, the medium introduced into the heating jacket I6, the heating jacket II7 and the heating jacket III8 ...

Embodiment 2

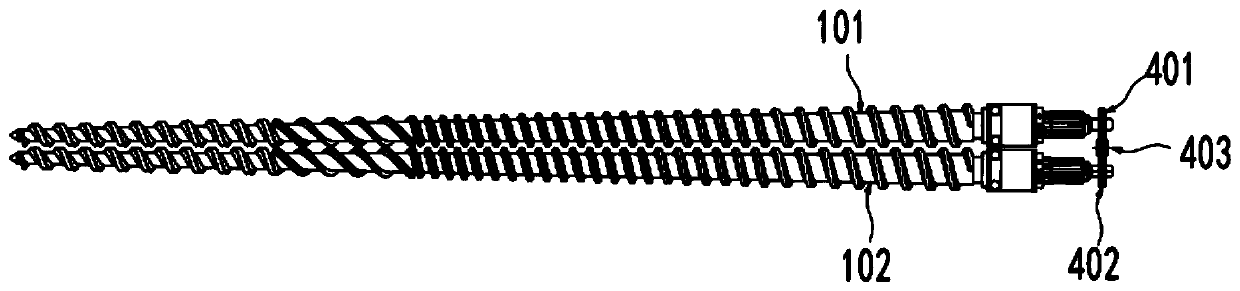

[0027] see Figure 1~3 , in the embodiment of the present invention, a HDPE plastic pipe molding equipment, the barrel 1 is installed with conical screw I101 and conical screw II102 arranged in the same direction, used for plasticizing and banburying raw materials, of course the conical screw The feeding directions of the conical screw I101 and the conical screw II102 are consistent.

[0028] Specifically, a driving motor 2 is installed at one side of the barrel 1, and the driving motor 2 drives the conical screw I101 and the conical screw II102 to rotate in the same direction and at the same speed through the reduction box 3 and the transmission box 4. Specifically: the shaft ends of the conical screw I101 and the conical screw II102 are respectively equipped with a driven gear I401 and a driven gear II402, and the driven gear I401 and the driven gear II402 are kept in mesh with the driving gear 403, and the driving gear The gear 403 is installed on the output shaft of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com