Frit glue printing equipment and method

A printing equipment, printing offset technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of Frit offset printing difficulties, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

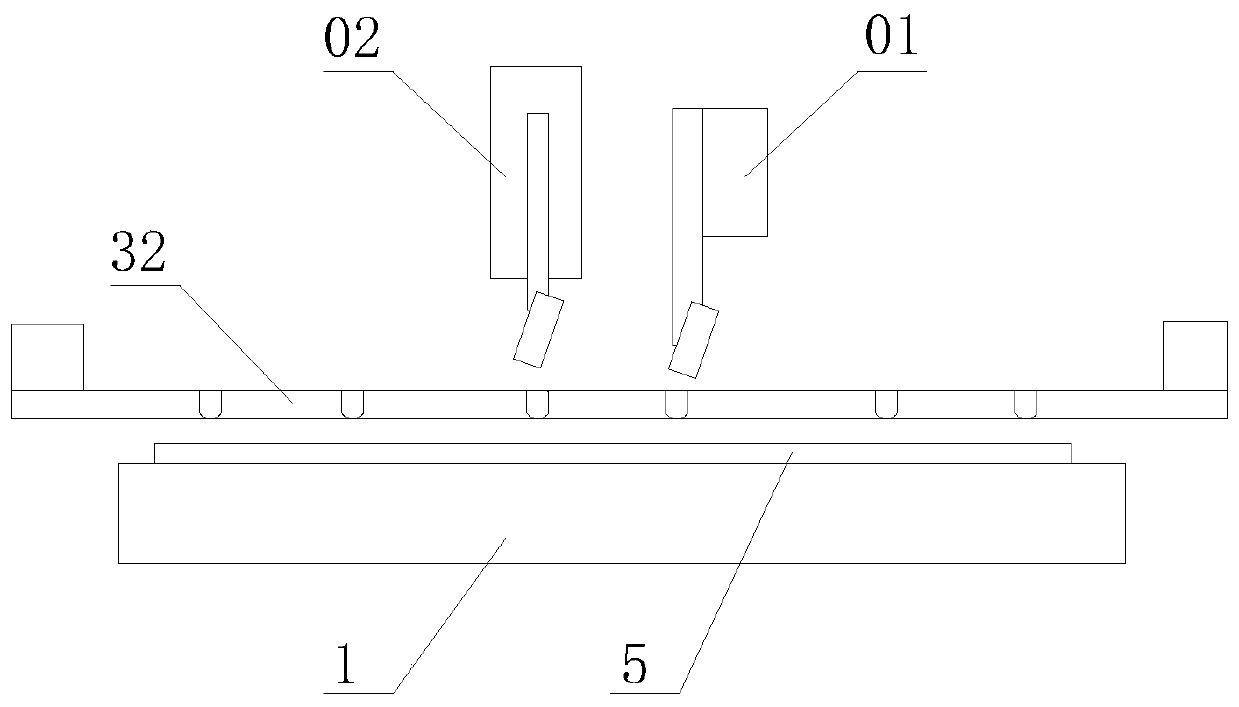

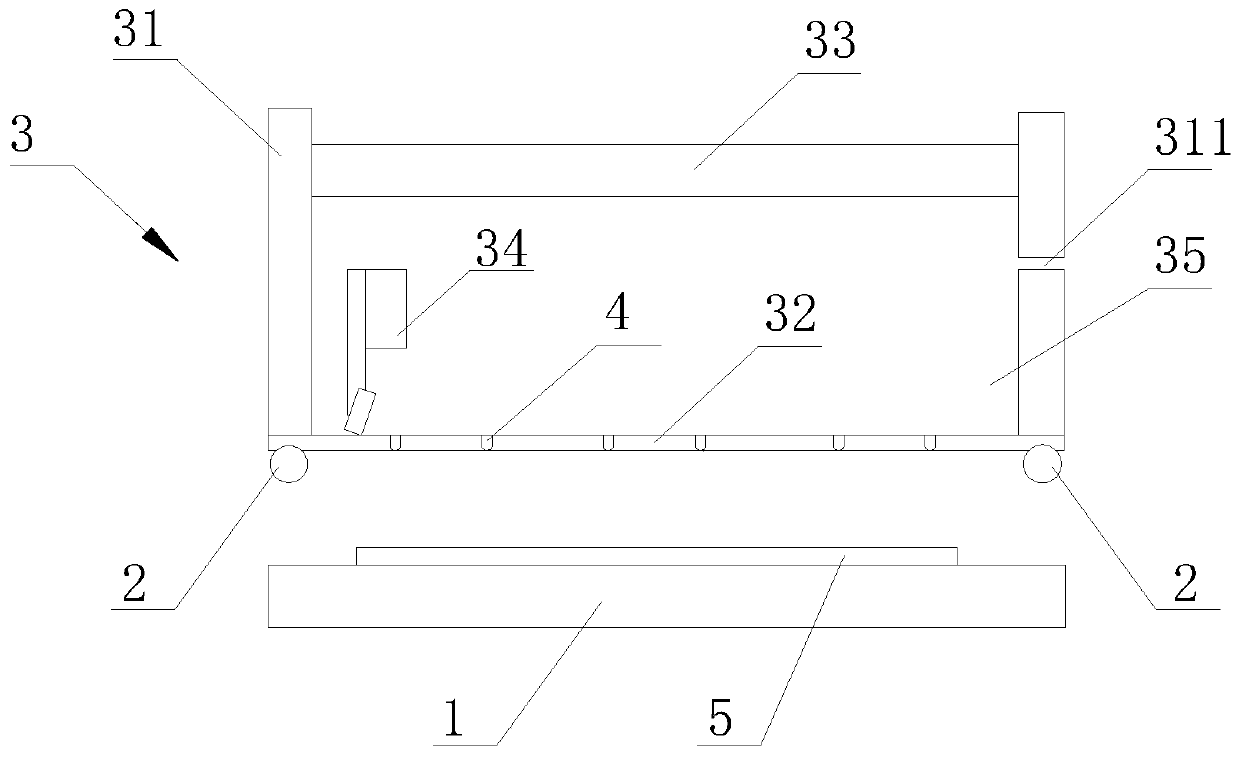

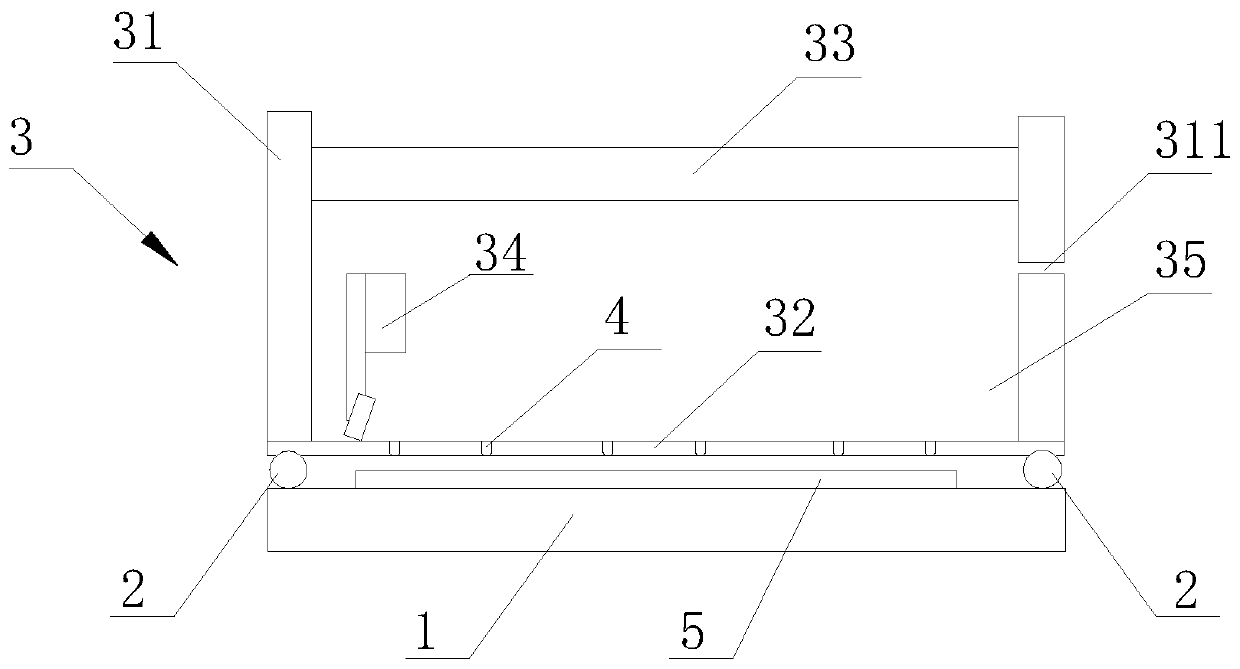

[0042] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0043] see Figure 2 to Figure 5 , the present embodiment provides a kind of Frit glue printing equipment, including a workbench 1, a sealing ring 2 and a glue printing mechanism 3, the workbench is used to place the glass 5 to be printed, and the glue printing mechanism is arranged above the workbench After the printed glass is placed on the workbench, the printing mechanism will print Frit glue 4 on the upper surface of the glass.

[0044] At the initial position, there is a certain gap between the rubber printing mechanism and the workbench, the purpose of which is to facilitate placing the glass to be printed on the corresponding position of the workbench; Move downward towards the working table until the rubber printing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com