Intelligent sewing machine

A sewing machine, intelligent technology, applied in the field of sewing machines, can solve problems such as empty stitching, sewing thread breakage, etc., achieve good protection, ensure sewing quality, and good practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

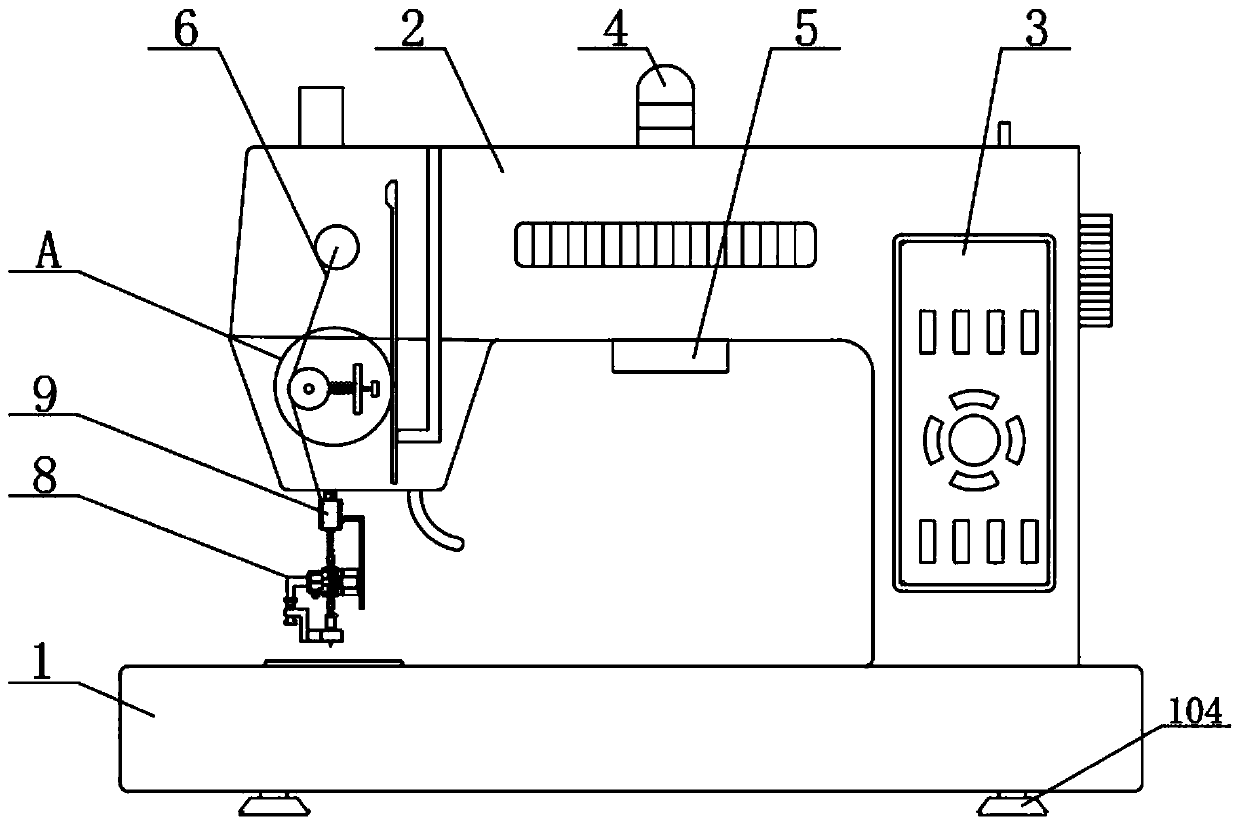

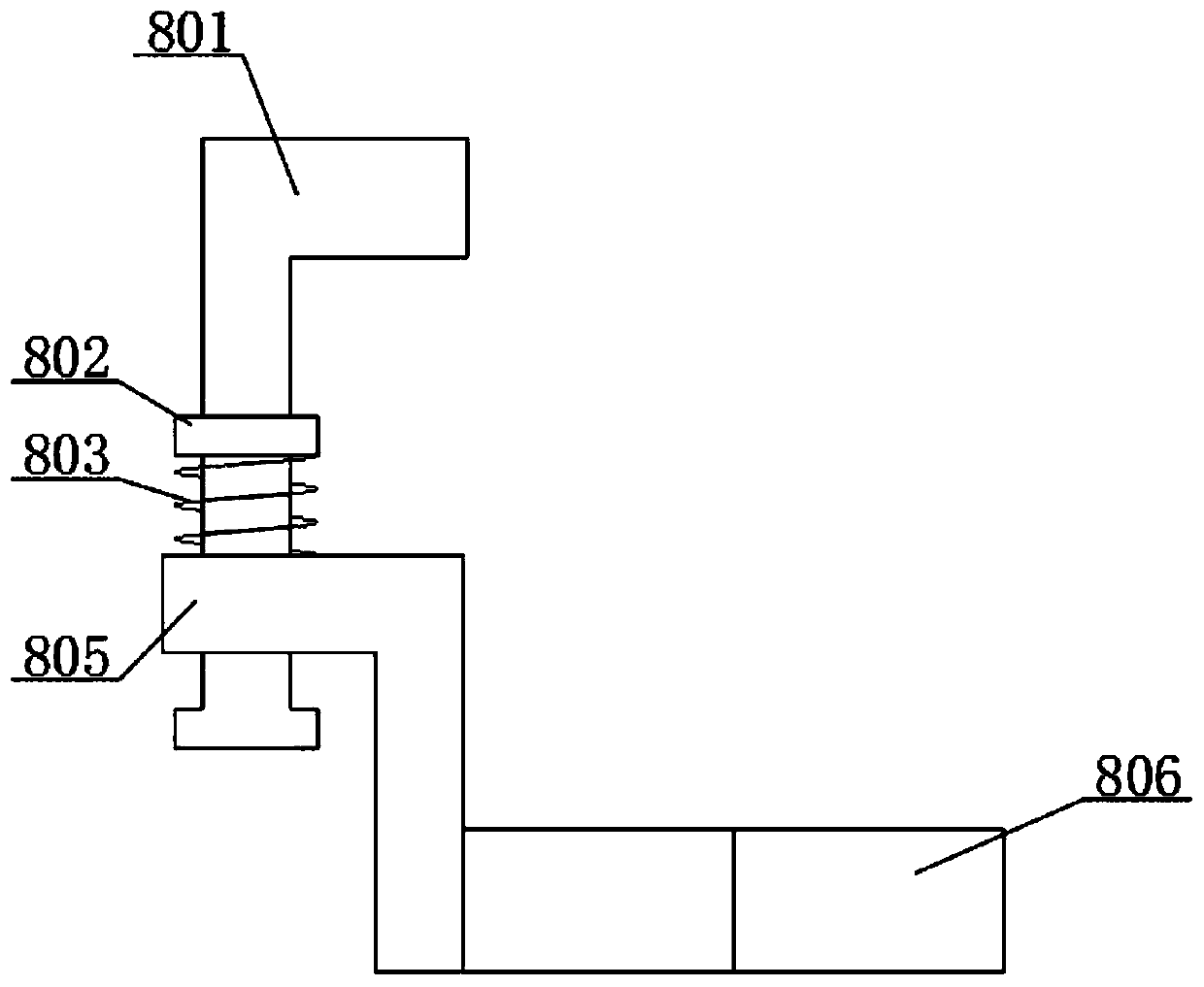

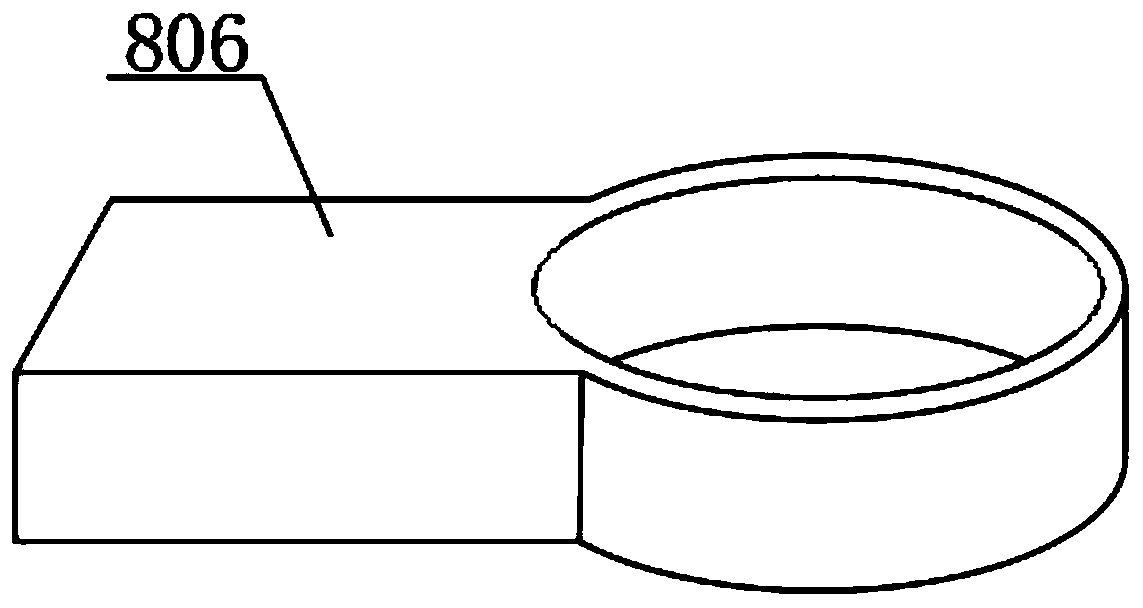

[0022] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , the present invention provides a kind of technical scheme:

[0023] An intelligent sewing machine, comprising a housing 2 and a control panel 3, the lower end of the housing 2 is fixedly connected with an adjustment mechanism 1, the adjustment mechanism 1 includes a base 101, an electric telescopic rod 102 and a sliding cylinder 103, and the center of the base 101 is fixedly connected with a rotating Motor 105, rotating motor 105 provides rotational power, the end of rotating motor 105 main shaft is fixedly connected with threaded rod 106, threaded rod 106 outside is spirally connected with threaded cylinder 107, the upper end of threaded cylinder 107 is fixedly connected with sealing sliding plate 108, sealing sliding plate 108 The outer side is slidingly connected with a sealing box 109, the outer side of the sealing box 109 is fixedly connected with the base 101, and the outer side of the...

Embodiment 2

[0027] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , the present invention provides a technical solution:

[0028] An intelligent sewing machine, comprising a housing 2 and a control panel 3, the lower end of the housing 2 is fixedly connected with an adjustment mechanism 1, the adjustment mechanism 1 includes a base 101, an electric telescopic rod 102 and a sliding cylinder 103, and the center of the base 101 is fixedly connected with a rotating Motor 105, rotating motor 105 provides rotational power, the end of rotating motor 105 main shaft is fixedly connected with threaded rod 106, threaded rod 106 outside is spirally connected with threaded cylinder 107, the upper end of threaded cylinder 107 is fixedly connected with sealing sliding plate 108, sealing sliding plate 108 The outer side is slidingly connected with a sealing box 109, the outer side of the sealing box 109 is fixedly connected with the base 101, and the outer side of the seali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com