A single-tub washing machine assembly and washing machine

A washing machine and component technology, applied in the field of washing machines, can solve the problems of heavy inner and outer tubs and difficult cleaning of dirt, and achieve the effects of reducing the chance of dirt, reducing materials, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

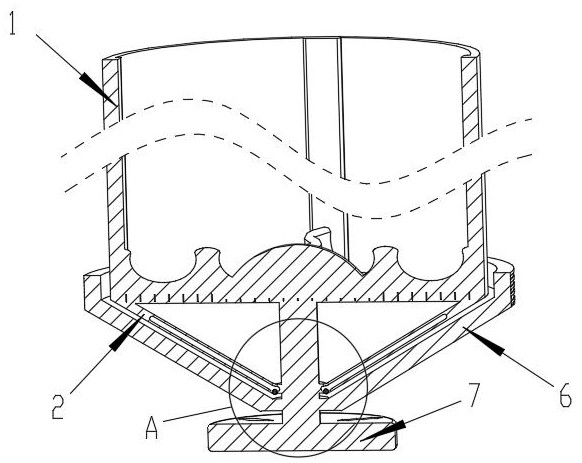

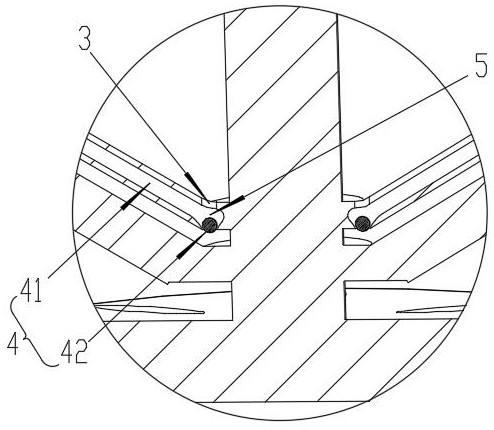

[0023] A kind of single-tub washing machine assembly of this embodiment, such as Figure 1-2 As shown, it includes a bucket body 1, the bottom of the bucket body 1 is a frustum 2, the bottom of the frustum 2 is provided with at least one drainage hole 3, and the side wall of the frustum 2 is provided with a drainage hole for controlling 3 of the switches of the switch assembly 4 . A single barrel design is adopted, and a frustum 2 is set at the bottom of the barrel body 1, and a drain hole 3 is set at the bottom of the frustum 2 and a switch assembly 4 of the drain hole 3 is set on the side wall to control the switch of the drain hole 3. When the washing machine is washing, the switch assembly 4 closes the drain hole 3, and when the washing machine is dehydrating, the switch assembly 4 opens the drain hole 3, so that the washing machine can switch between washing and dehydration functions even if the washing machine uses a single tub, reducing the chance of the washing machine...

Embodiment 2

[0033] The other structures of this embodiment are the same as in Embodiment 1, except that the ball 42 is made of ceramic material, and the ball 42 made of ceramic material also has strong wear resistance and corrosion resistance, which can increase the service life of the washing machine. Because ceramics are lighter than stainless steel, the size of the drainage hole 3 can be larger than that of Embodiment 1, which increases the drainage rate.

Embodiment 3

[0035] Other structures of this embodiment are the same as in Embodiment 1, except that the ball 42 is hollow, and the ball 42 that is hollow can increase in size while ensuring the same quality, because the size of the ball 42 is increased , the size of the corresponding drainage holes 3 can also be increased, thereby increasing the drainage rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com