A new type of piling noise reduction device

A new type of high-pressure pipe technology, applied in sheet pile walls, buildings, instruments, etc., can solve the problems of noise pollution in the marine environment, affecting the living environment of marine organisms, affecting human life activities, etc., and achieve the effect of reducing continuous and impact noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further explained in detail below in conjunction with the accompanying drawings and specific embodiments, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

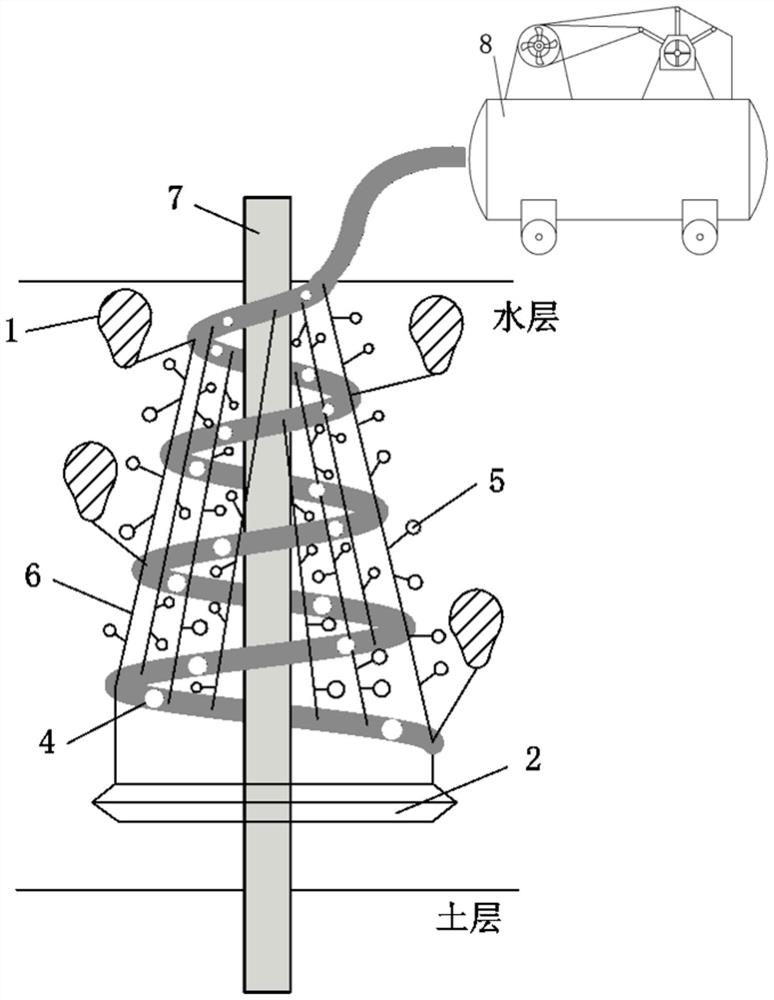

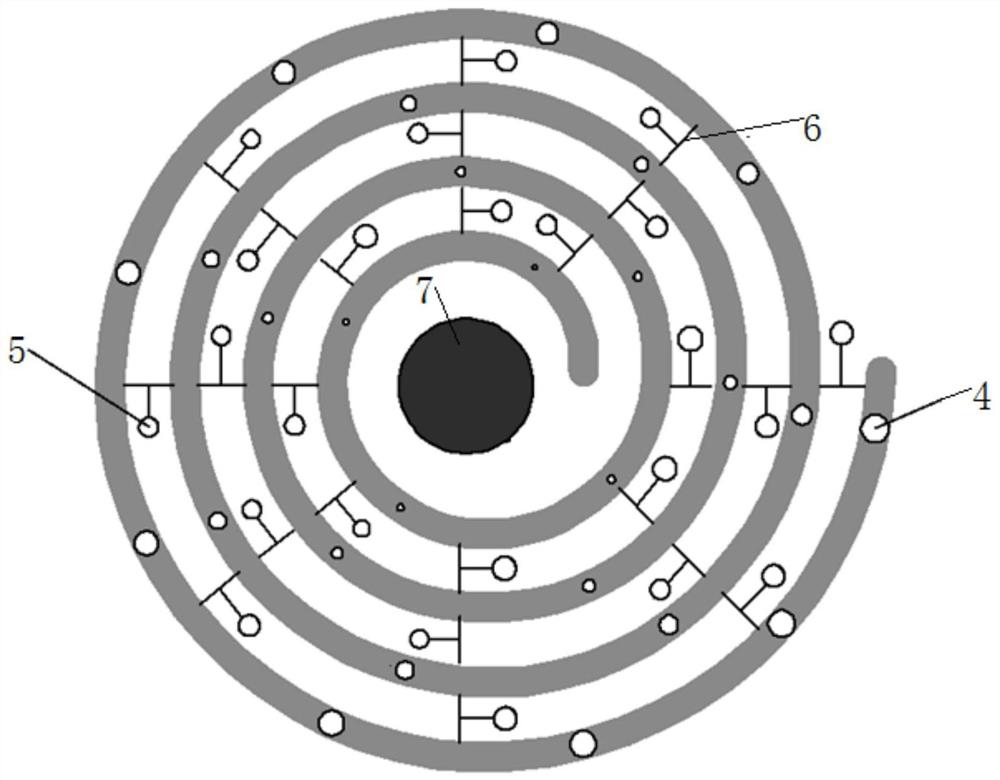

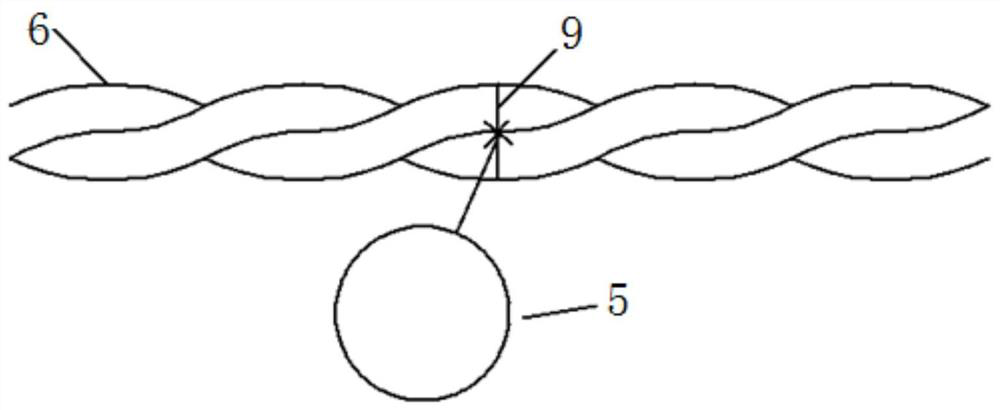

[0023] Such as figure 1 As shown, the piling noise reduction device in the present invention includes a noise reduction mechanism, an underwater air bag 1 arranged on the noise reduction mechanism from top to bottom, and a ballast device 2 arranged at the second end of the noise reduction mechanism. The noise reduction mechanism It is a cone structure with a large opening at one end and a small opening at the other end. It can also be called a trumpet structure. The large mouth end and the small mouth end are connected, and neither the large mouth end nor the small mouth end is closed. The large mouth end of the structure is connected to the ballast device 2, and the underwater airbag 1 is arranged from top to bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com