Suction bucket underwater pile-driving noise-reduction device and construction method thereof

A suction barrel and noise reduction technology, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems that the noise reduction net does not take into account the noise distribution, and the noise reduction does not achieve the best effect, so as to ensure stability , high-efficiency resonance, and noise-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

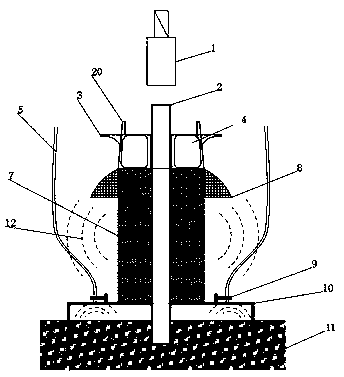

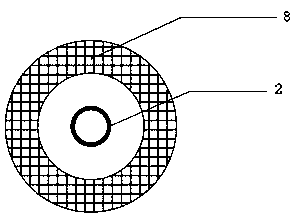

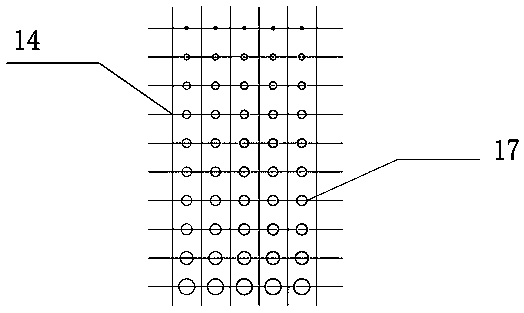

[0029] Such as figure 1 As shown, the present invention proposes a suction bucket type underwater piling noise reduction device, which includes a buoyancy ring base 3 floating on the water surface; the buoyancy ring base 3 surrounds the outer periphery of the pile body 2; Barrel device; the suction barrel device surrounds the outer periphery of the pile body 2, and the suction barrel device is sealed and connected with the outer wall of the pile body 2; the first noise reduction net 7 surrounding the periphery of the pile body 2; the first noise reduction net 7 The upper end is connected with the buoyancy ring base 3, the lower end of the first noise reduction net 7 is connected with the suction barrel device; the second noise reduction net 8 surrounding the outside of the first noise reduction net 7; the upper end of the second noise reduction net 8 It is connected with the buoyancy ring base 3 on the water surface, and the lower end of the second noise reduction net 8 is a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com