One-way non-lost motion friction damper

A friction damper, one-way technology, applied in building types, buildings, building components, etc., can solve problems such as immediate increase and decrease of damper working efficiency, and the transmission shaft cannot drive the main board, so as to avoid buckling or damage under compression. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

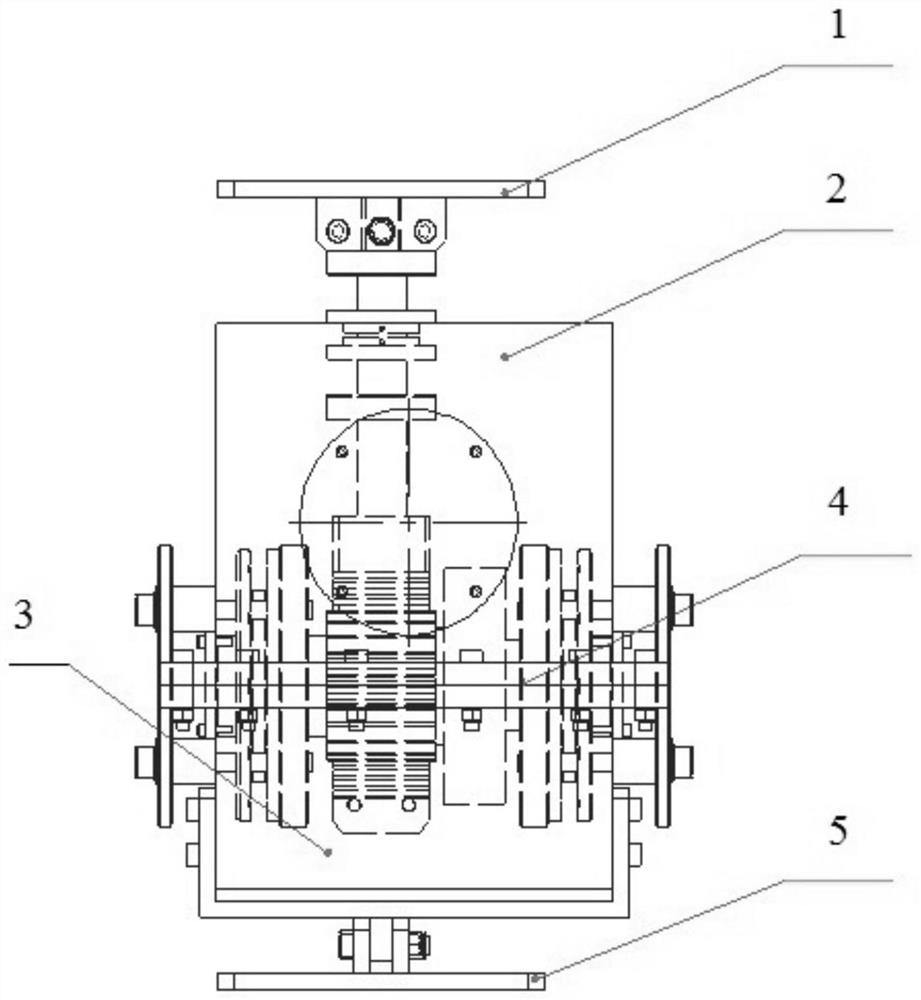

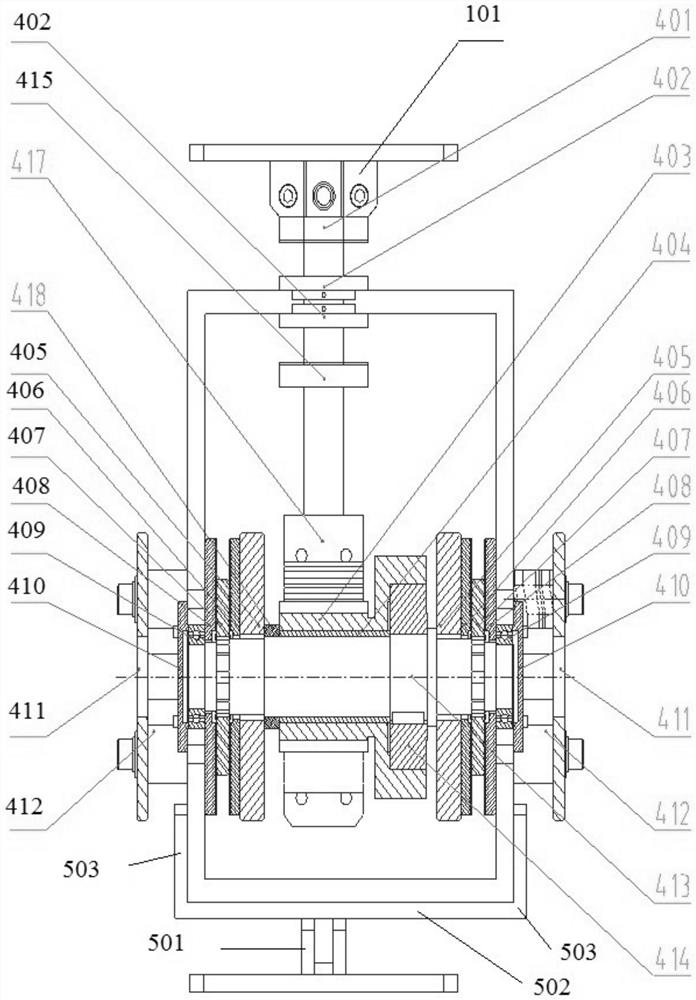

[0046] Such as Figure 1-4 As shown, a one-way non-lost motion friction damper, the damper includes:

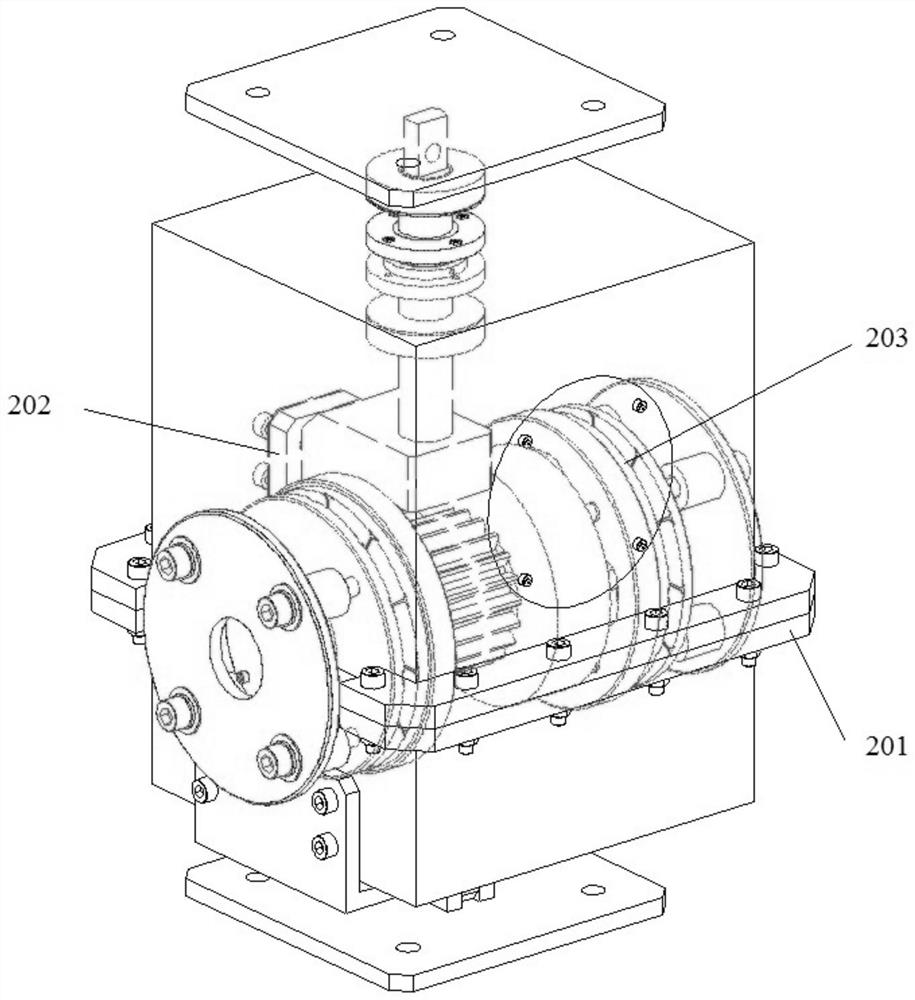

[0047] An outer casing with a hole on the upper side, the outer casing is a split casing, including an upper casing 2 and a lower casing, and a separate boss 201 is provided along the junction of the upper casing 2 and the lower casing 3, and the split boss The platforms 201 are fixed by bolts, the inner wall of the upper shell 2 and the lower shell 3 is provided with a connecting plate 202, the upper end of the connecting plate 202 is fixedly connected with the upper shell 2, the lower end is fixedly connected with the lower shell 3, and the side of the upper shell 2 is provided with a circle The hole 203 is facing the driving gear 403;

[0048] A brake assembly 4 is located inside the outer shell, and the brake assembly 4 includes:

[0049] An optical axis 416 passes through the hole of the outer shell. The upper limit block 401 and the lower limit block 415 are arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com