A laser displacement sensor vibration compensation platform

A laser displacement and vibration compensation technology, applied in instruments, optical devices, measuring devices, etc., can solve the problems of being easily affected by vibration, such as measurement accuracy, and achieve the effect of simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

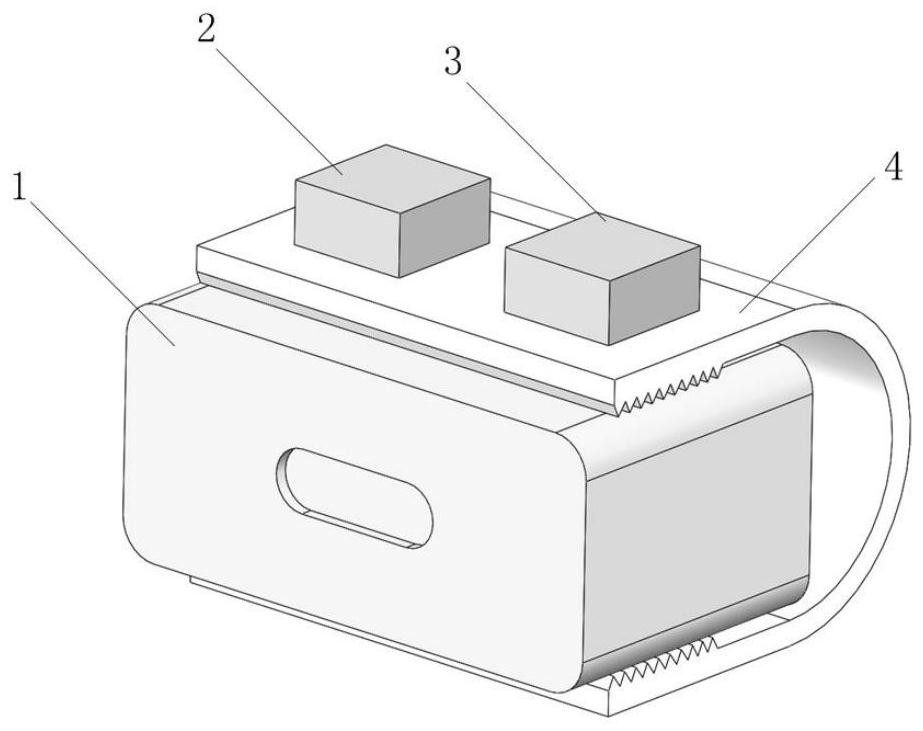

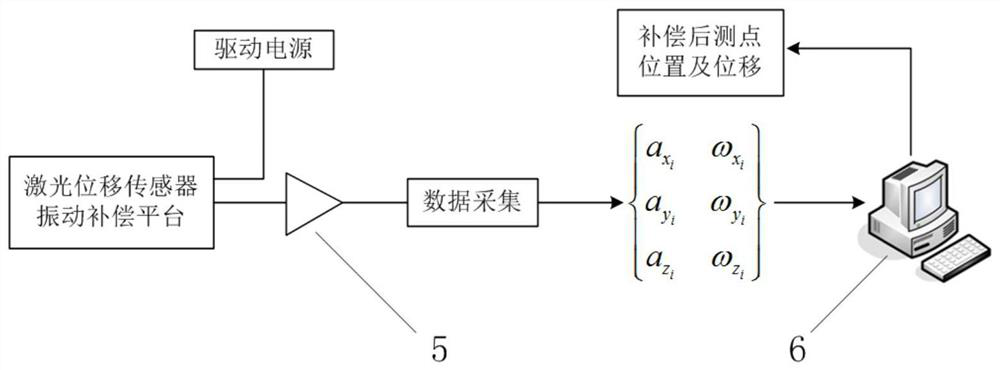

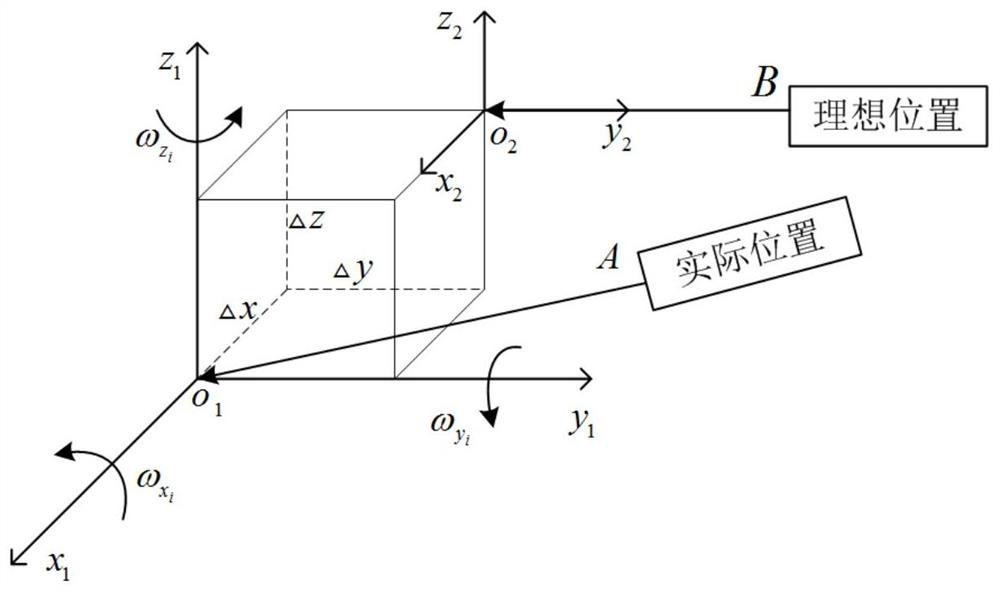

[0037] Such as Figure 1-3 As shown, the present invention provides a laser displacement sensor vibration compensation platform, including a laser measurement device, a signal processor and a compensation calculation device;

[0038] The laser measurement device includes a laser displacement sensor 1, an acceleration sensor 2, an angular velocity sensor 3 and a fixture 4; the acceleration sensor 2 and the angular velocity sensor 3 are fixedly mounted on the fixture 4; the fixture 4 clamps the laser Displacement sensor 1;

[0039] Described signal processor comprises data acquisition card and signal amplifier 5; Described data acquisition card and described signal amplifier 5 are all electrically connected with described laser displacement sensor 1, described acceleration sensor 2 and described angular velocity sensor 3 respectively, so The data acquisition card is used to collect the output voltage of the laser displacement sensor 1, the acceleration sensor 2 and the angular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com