Soft sensor modeling method for industrial non-stationary process based on local weighting factor model

A factor model and local weighting technology, applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve the problems that process dynamics and nonlinearity are not fully considered, achieve short prediction time, realize online estimation, The effect of accurate prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

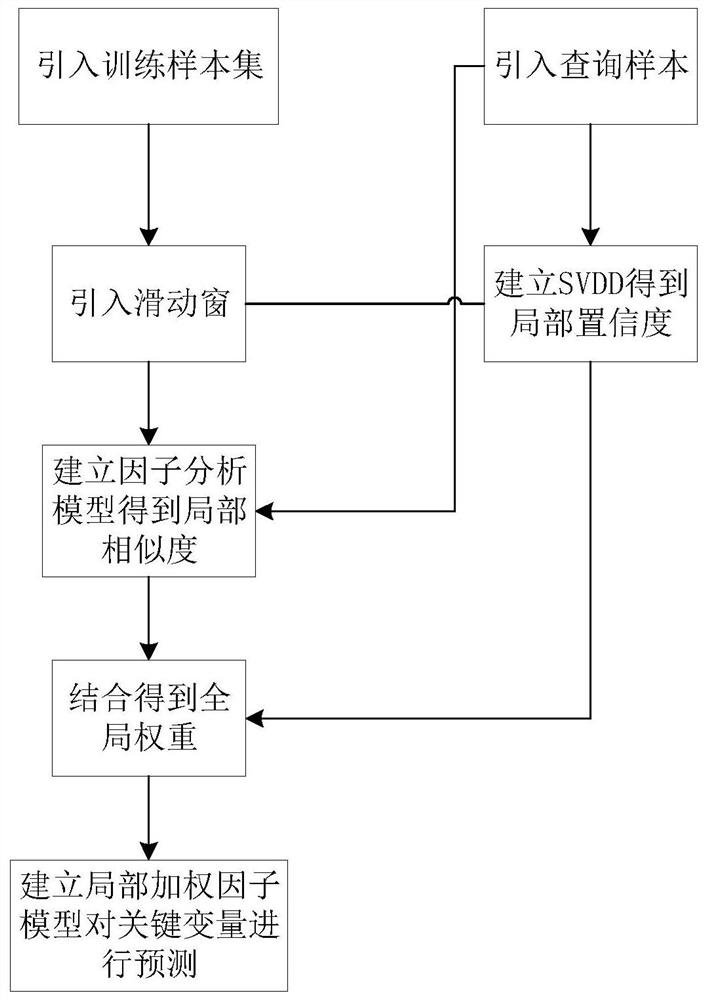

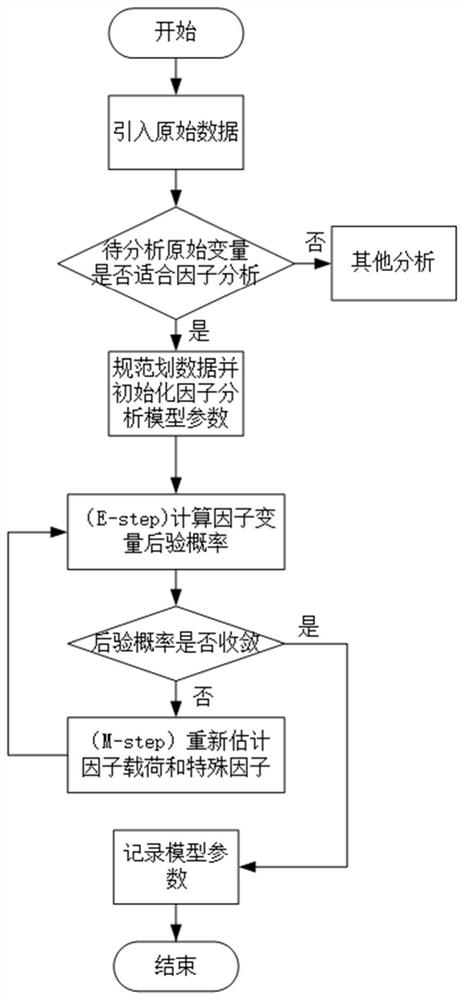

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with drawings and embodiments.

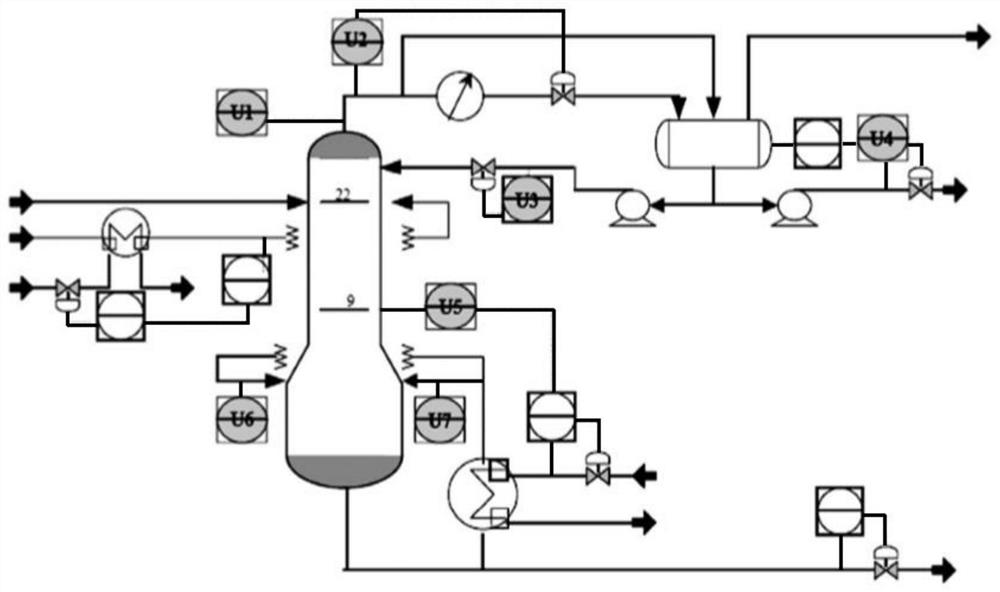

[0067] The invention aims at the problem of detecting the butane content in the debutanizer, by using the variables that are easy to measure in the process, and using a local weighting factor analysis model, the online soft measurement is performed on the butane content in the process.

[0068] Embodiments of the present invention and its implementation process are as follows:

[0069] Step 1: Collect data of various process variables in debutanizer through distributed control system and real-time database system: training sample set X trian ∈R N×n , store these data in the historical database, and select some data as samples for modeling.

[0070] Step 2: Obtain the butane content value corresponding to the sample used for modeling in the historical database through on-site extraction and offline laboratory analysis as the output Y of the soft sensor model trian ∈R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com