Central temperature estimation method of crossed temperature measurement device of blast furnace

A technology of cross temperature measurement and center temperature, which is applied to blast furnaces, inspection devices, blast furnace details, etc., can solve the problems of easy damage of temperature point sensors, long replacement cycle, and inability to continuously measure temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

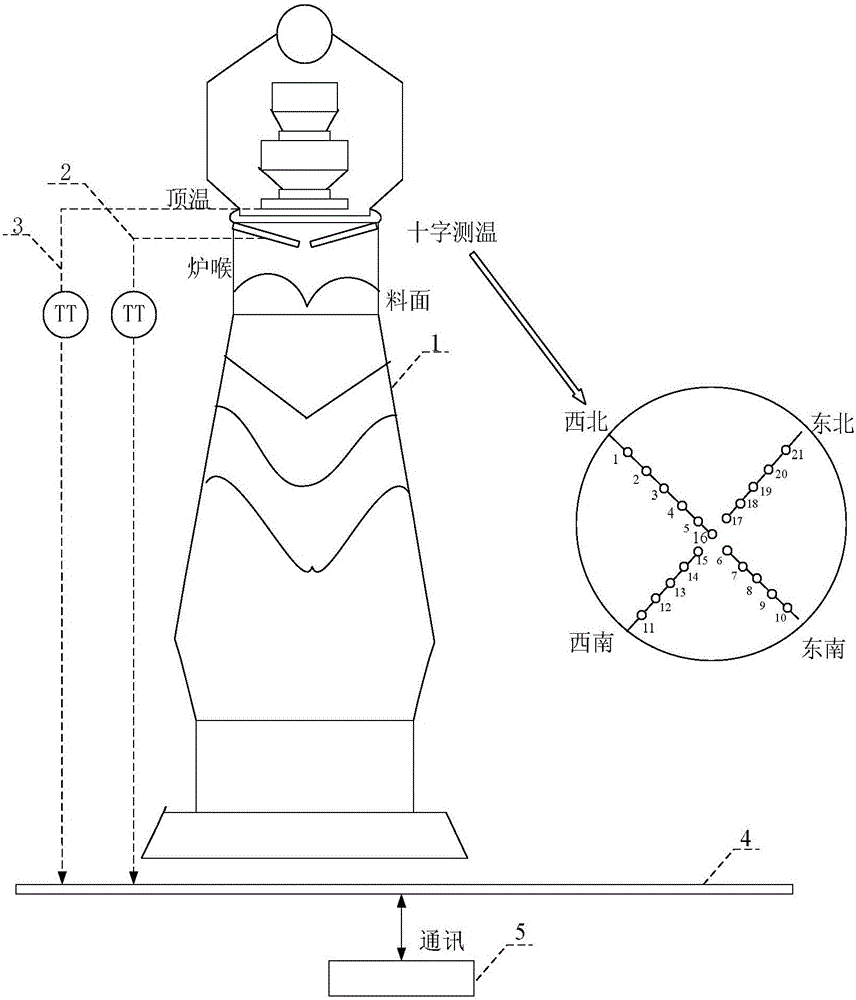

[0095] like figure 1 As shown, the cross temperature measuring device and the top temperature measuring device are respectively installed at the corresponding positions of the furnace throat and the furnace roof. The data collector is connected to the temperature measuring system, and connected to the computer system running the M-SVR estimation software through the communication bus.

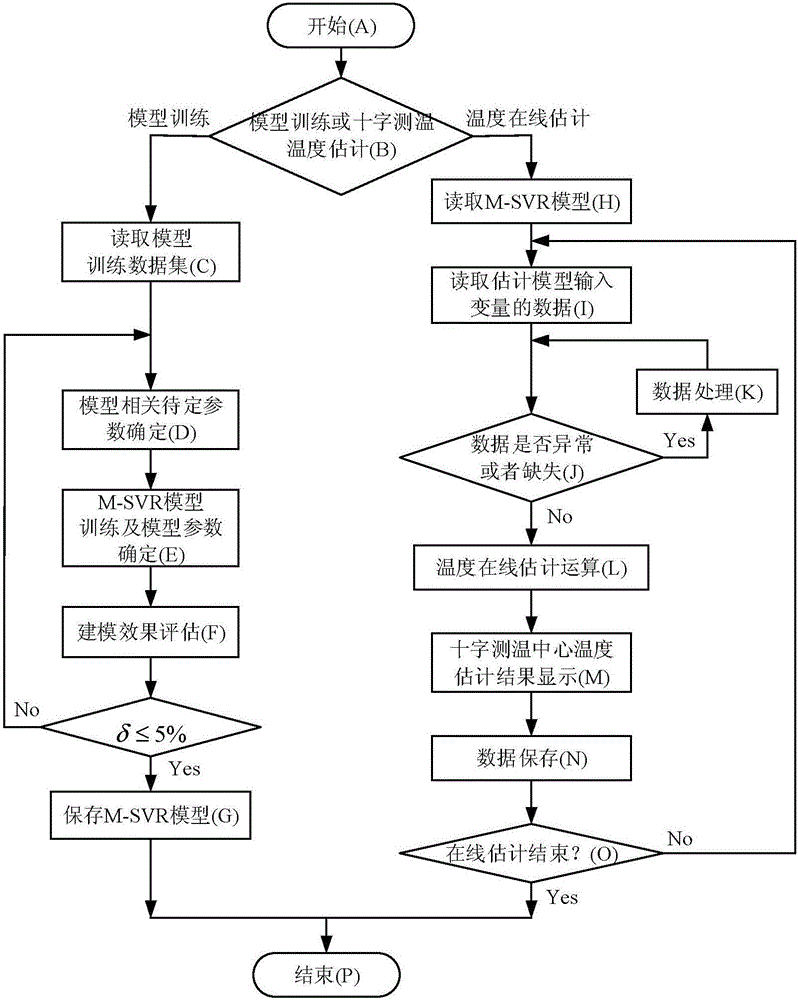

[0096] The realization method of the present invention includes (1) determination of model input variables (2) determination of modeling strategy (3) determination of model training samples (4) training and use of M-SVR estimation model.

[0097] For convenience of description, the symbols and terms used in the present invention are defined as follows:

[0098] The temperature of temperature measurement point 3 at the current sampling time x 1 (t)(°C);

[0099] Temperature measurement point 4 at the current sampling time x 2 (t)(°C);

[0100] Temperature measurement point 8 temperature at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com