Drums for carding machines

A technology of carding machine and drum, which is applied in the field of drum for carding machine, and can solve the problems of reducing quality, affecting thermal expansion, and being expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

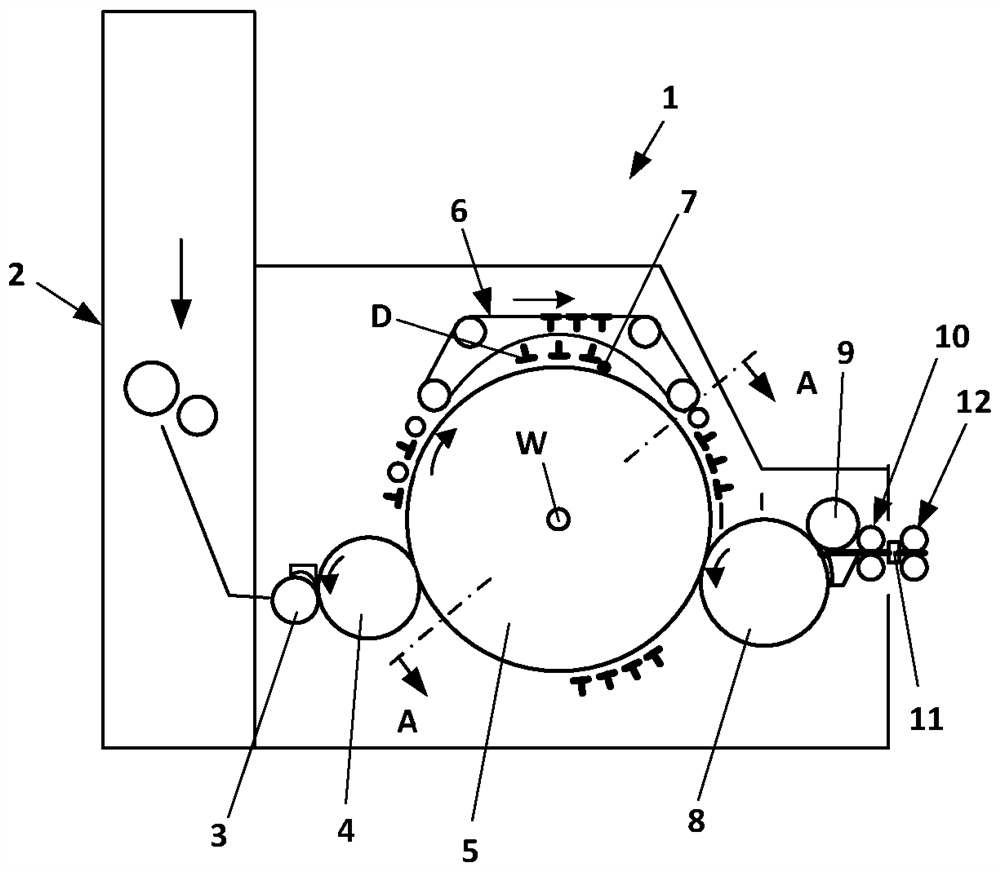

[0021] figure 1 A card 1 is shown having a feed chute 2 through which fibrous material in the form of nonwoven fibers is supplied from a feed roll 3 . From the feed roll 3 the fibrous material is sent to the licker-in roll 4, which transfers the fibrous material to the carding cylinder 5 (referred to simply as "drum") of the card 1 . Due to the rotational movement of the drum 5 around its axis (W-axis) (indicated by the arrow), the fiber material entrained by the drum 5 is displaced and enters the area of the main carding zone 7 which is connected above the drum 5 Rotating rotary flat units 6 are formed in combination. The direction of rotation of the rotary flat unit 6 is indicated by an arrow. The rotating flat unit 6 is provided with a schematically shown rotating flat bar D which is equipped with a card clothing (not shown).

[0022] After the main carding section 7 , the carded fiber material enters the area of a rotatably mounted doffer 8 , which transfers the fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com