Shoulder joint microscope rotator cuff repair locator

A technology of shoulder arthroscopy and locator, which is applied in the field of medical devices, can solve problems such as large fixation tension, pulling force of anchor falling off, and secondary damage to the patient's affected area, so as to save operation time, improve operation success rate, and reduce The Effect of Surgical Risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

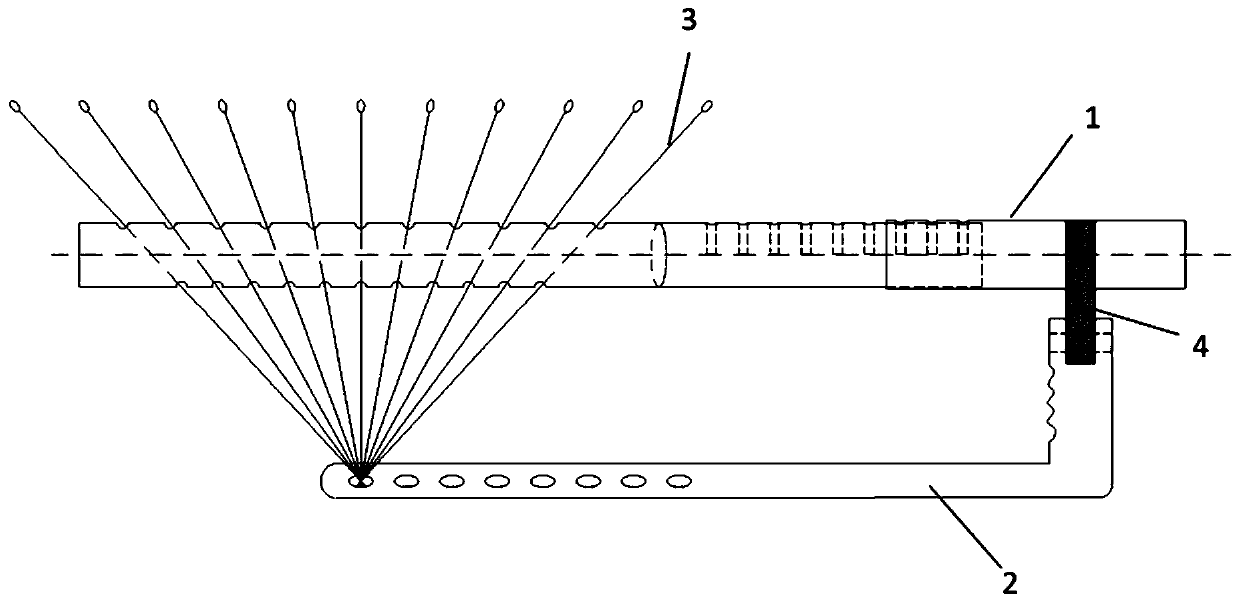

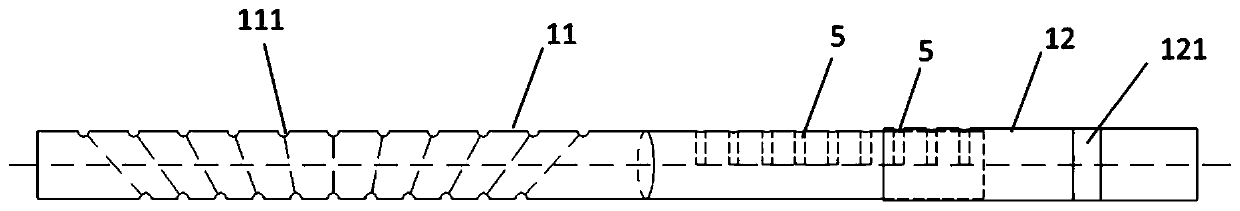

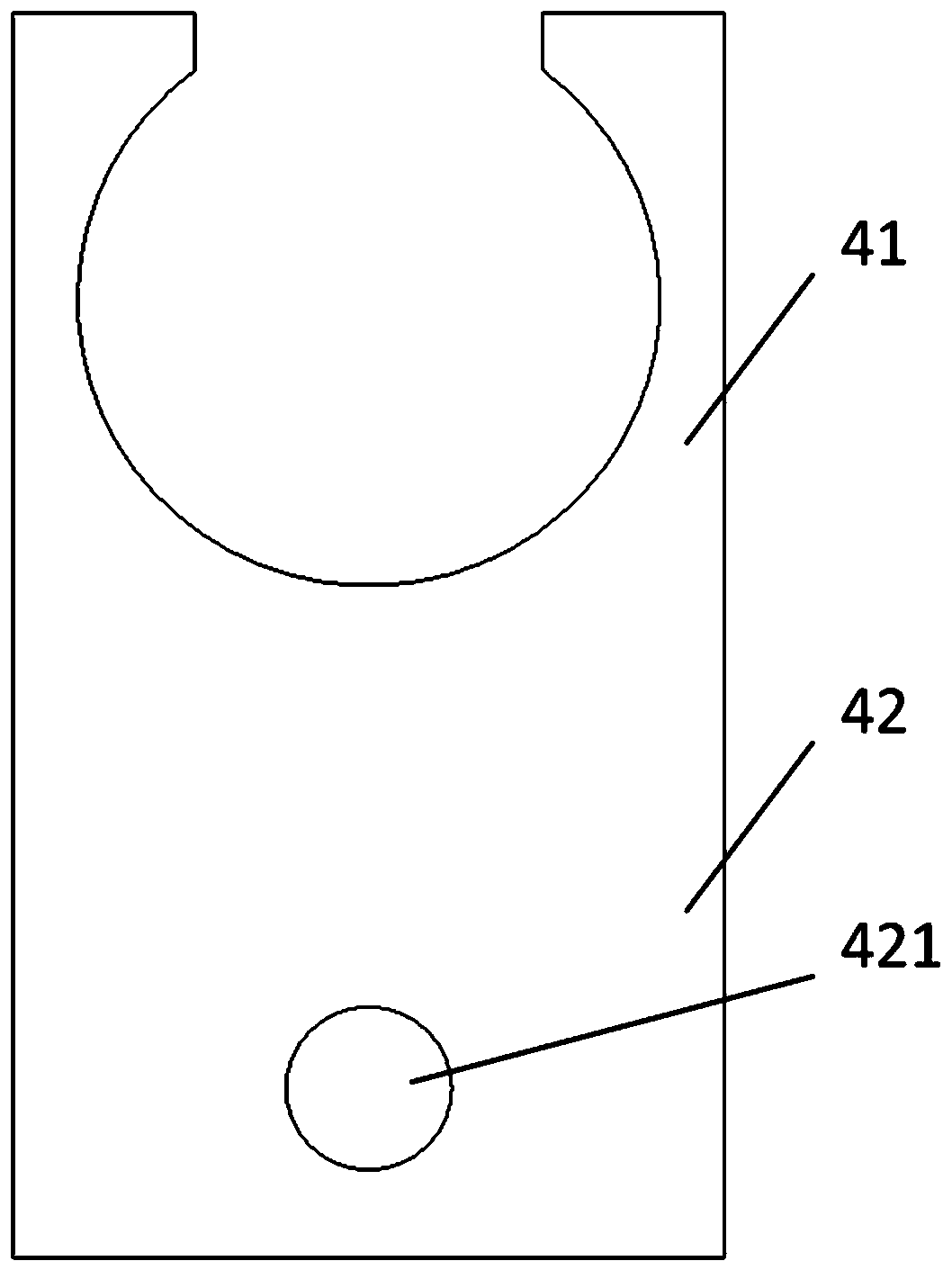

[0034]A rotator cuff repair positioner under shoulder arthroscopy, comprising a suture needle guide part 1 and a suture needle positioning part 2 (the suture needle guide part 1 and the suture needle positioning part 2 are titanium alloy), the suture needle guide part 1 is divided into flat The needle insertion part 11 and the cylindrical fixing part 12, the flat needle insertion part 11 is provided with a plurality of needle insertion holes 111 with different angles along its length direction, and the needle insertion holes 111 all pass through the centerline of the flat needle insertion part 11; One end of the needle-shaped needle insertion portion 11 is sleeved in the cylindrical fixing portion 12 , and the flat needle insertion portion 11 and the cylindrical fixing portion 12 are both provided with adjustment holes 5 corresponding to the positions. The suture needle positioning part 2 is divided into a vertical part 21 and a horizontal part 22 which are perpendicular to eac...

Embodiment 2

[0038] A rotator cuff repair positioner under shoulder arthroscopy, comprising a suture needle guide part 1 and a suture needle positioning part 2 (the suture needle guide part 1 and the suture needle positioning part 2 are titanium alloy), the suture needle guide part 1 is divided into flat The needle insertion part 11 and the cylindrical fixing part 12, the flat needle insertion part 11 is provided with a plurality of needle insertion holes 111 with different angles along its length direction, and the needle insertion holes 111 all pass through the centerline of the flat needle insertion part 11; One end of the needle-shaped needle insertion portion 11 is sleeved in the cylindrical fixing portion 12 , and the flat needle insertion portion 11 and the cylindrical fixing portion 12 are both provided with adjustment holes 5 corresponding to the positions. The suture needle positioning part 2 is divided into a vertical part 21 and a horizontal part 22 which are perpendicular to ea...

Embodiment 3

[0042] A rotator cuff repair positioner under shoulder arthroscopy, comprising a suture needle guide part 1 and a suture needle positioning part 2 (the suture needle guide part 1 and the suture needle positioning part 2 are titanium alloy), the suture needle guide part 1 is divided into flat The needle insertion part 11 and the cylindrical fixing part 12, the flat needle insertion part 11 is provided with a plurality of needle insertion holes 111 with different angles along its length direction, and the needle insertion holes 111 all pass through the centerline of the flat needle insertion part 11; One end of the needle-shaped needle insertion portion 11 is sleeved in the cylindrical fixing portion 12 , and the flat needle insertion portion 11 and the cylindrical fixing portion 12 are both provided with adjustment holes 5 corresponding to the positions. The suture needle positioning part 2 is divided into a vertical part 21 and a horizontal part 22 which are perpendicular to ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com