A method for the purification and separation of artemisinin enhanced by chitosan functional membrane

A technology of purification and separation, chitosan, applied in chemical instruments and methods, ion exchange, organic chemistry, etc., can solve the problems of complicated separation steps, achieve efficient purification and separation methods, improve purity, and strengthen the effect of purification and separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

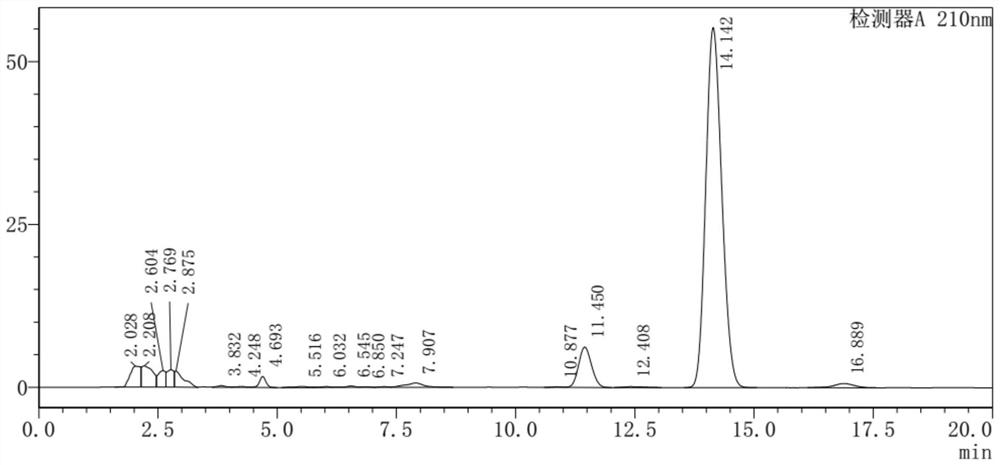

[0054] Dissolve 1g of extract in 7mL of 70% aqueous methanol, stir at 55°C for 0.5h, filter to obtain an extract containing artemisinin and wax oil, then add 0.2g of C 8 Modified chitosan functional membrane, stirred at 30°C for 2h, placed in a low-temperature constant temperature tank, crystallized at 25°C for 1h, filtered, and dried at 50°C, the HPLC spectrum of the obtained product is as follows: figure 1 As shown, the peak eluting time is 14.048min, and the purity of artemisinin is 98.4%.

[0055] Wherein, the preparation method of modified chitosan functional film is: add 5mL tetraethyl orthosilicate and 5mL n-octyltrimethoxysilane in 85mL ethanol, the volume ratio of tetraethyl orthosilicate and ethanol is 1:17, stir 0.5h; after adding 0.1g of chitosan functional film, quickly add a mixed solution containing 5mL of ammonia water and 35mL of water. The mass concentration of ammonia water used in the experiment was 28%, stirred at room temperature for 4h, washed with ethan...

Embodiment 2

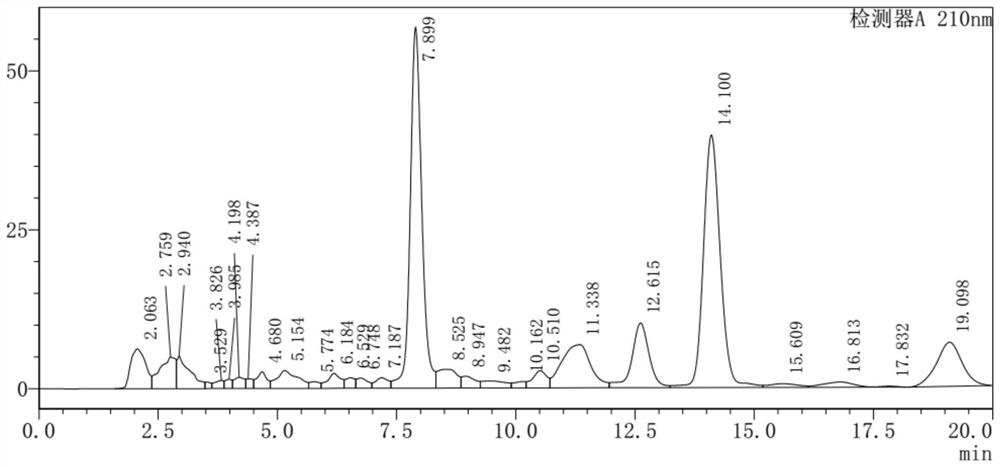

[0057] Dissolve 1g of extract in 7mL of 70% aqueous methanol, stir at 55°C for 0.5h, filter to obtain an extract containing artemisinin and wax oil, then add 0.03g of chitosan functional membrane, stir at 50°C for 2h, and place Crystallize in a low-temperature constant temperature bath at 10°C for 5 hours, filter, and dry at 50°C. The peak position similar to that of Example 1 was obtained by HPLC detection, the peak time was 14.041min, and the purity was 86.8%.

Embodiment 3

[0059] Dissolve 1g of extract in 7mL of 70% aqueous methanol, stir at 55°C for 0.5h, filter to obtain an extract containing artemisinin and wax oil, then add 0.2g of C 8 Modified chitosan functional film, stirred at 30°C for 2h, then placed in a low-temperature constant temperature tank for crystallization at 10°C for 1h, filtered, and dried at 50°C, the HPLC spectrum of the product obtained obtained a peak position similar to that of Example 1, and the peak time It was 14.079min, and the purity of artemisinin was 100%.

[0060] Wherein, the preparation method of the modified chitosan functional film is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com