Titanium alloy parts with uniform transverse and longitudinal properties and preparation method thereof

A titanium alloy, horizontal and vertical technology, applied in the field of titanium alloys, can solve problems such as low elongation, product damage, and inability to twist horizontal and vertical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

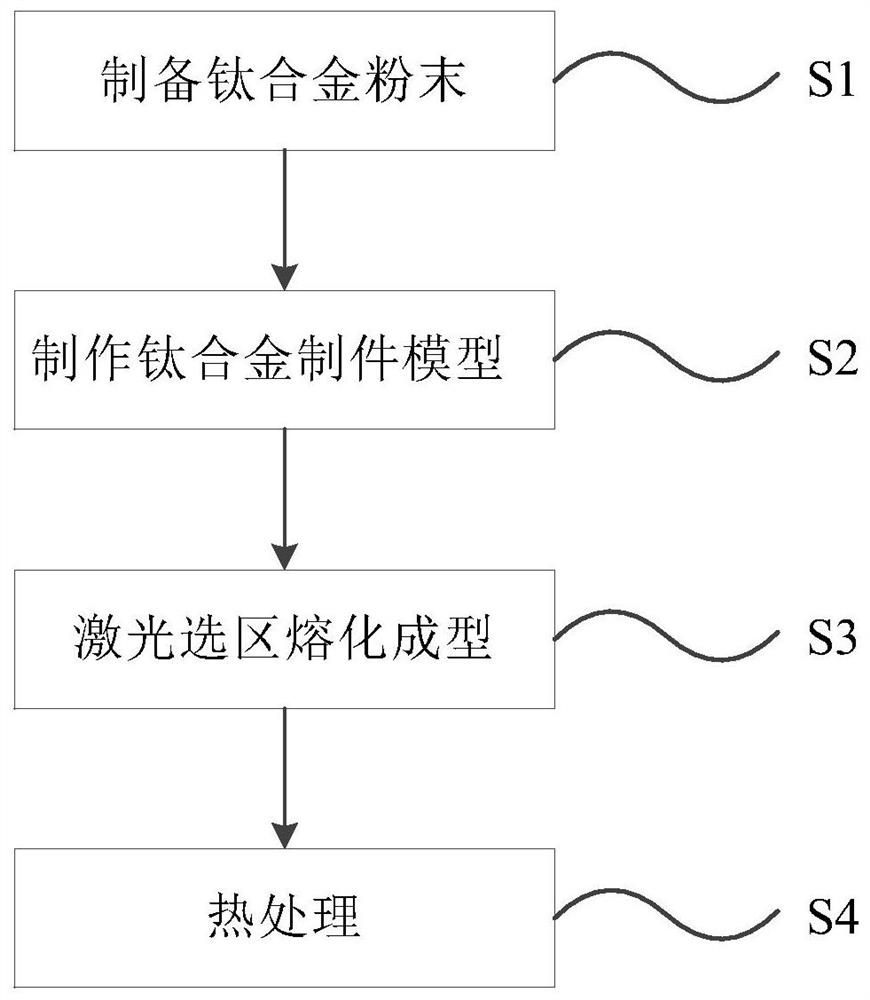

[0034] The technical scheme for preparing titanium alloy parts with uniform horizontal and vertical properties provided by the application is as follows:

[0035] By transforming at least a part of the martensite of the titanium alloy part into α phase and / or β phase during selective laser melting forming, to prepare the titanium alloy part; and

[0036] The titanium alloy parts are homogenized by heat treatment.

[0037] This application prepares titanium alloy parts by laser selective melting forming technology, and transforms at least a part of the martensite in the titanium alloy parts into α phase and / or β phase during the forming process, thereby improving the internal structure of the titanium alloy parts , and then reduce the difference in horizontal and vertical properties of titanium alloys.

[0038] Furthermore, the titanium alloy parts prepared by laser selective melting and forming, followed by heat treatment, further make the internal structure of the titanium a...

Embodiment 1

[0054] use figure 1 The shown process step prepares TC4 titanium alloy parts, specifically as follows:

[0055] TC4 titanium alloy powder was prepared by vacuum atomization technology, and the parameters of the prepared powder were as follows: D10 particle size was 19.32 μm, D50 particle size was 31.45 μm, D90 particle size was 48.76 μm; sphericity was 90%, bulk density was 2.15g / cm 3 , Tap density 2.58g / cm 3 , Hall flow rate 44s / 50g, hollow powder rate 0.1% and inclusion 0.05%.

[0056] Three-dimensional drawing software is used to draw the model of TC4 titanium alloy parts, three-dimensional digital model is converted into two-dimensional layer data by three-dimensional conversion two-dimensional data software, two-dimensional slice data is obtained, and it is imported into the system of laser selective melting and forming equipment .

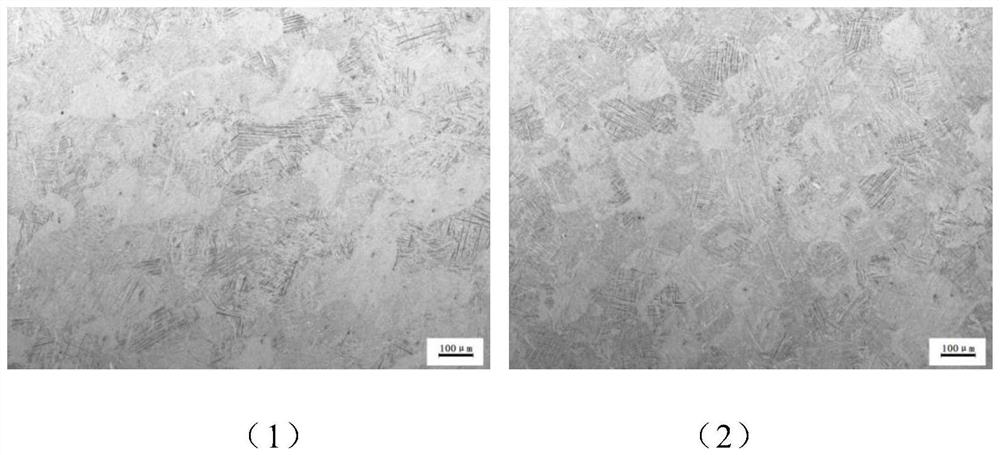

[0057] Set the molding process parameters: laser power 282W, scanning speed 1150mm / s, powder layer thickness 40μm, spot diameter 0.12mm...

Embodiment 2

[0069] use figure 1 The process steps shown prepare TA15 titanium alloy parts, specifically as follows:

[0070] TA15 titanium alloy powder was prepared by vacuum atomization technology. The parameters of the prepared powder are as follows: D10 particle size is 21.33 μm, D50 particle size is 38.56 μm, D90 particle size is 52.98 μm; sphericity 95%, bulk density 2.41g / cm 3 , Tap density 2.79g / cm 3 , Hall flow rate 35s / 50g, hollow flour rate 0.05% and inclusions 0.1%.

[0071] Three-dimensional drawing software is used to draw the model of TA15 titanium alloy parts, three-dimensional digital model is converted into two-dimensional layer data by three-dimensional conversion two-dimensional data software, two-dimensional slice data is obtained, and it is imported into the system of laser selective melting and forming equipment .

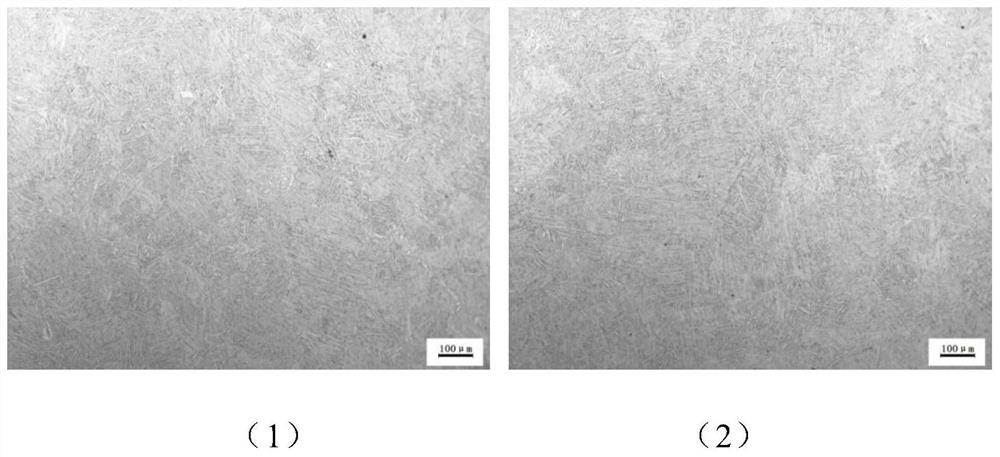

[0072] Set the molding process parameters: laser power 330W, scanning speed 1200mm / s, powder layer thickness 30μm, spot diameter 0.13mm, laser overl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com