A kind of wide-width steel plate with high uniform longitudinal and transverse toughness and TMCP process production method thereof

A vertically and horizontally uniform technology, applied in the field of high uniform vertically and laterally toughness wide steel plate and its TMCP process production, can solve the problems of supporting special equipment, large energy consumption, long process, etc., to meet the requirements of mass production and surplus strength and toughness The effect of large quantity and easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

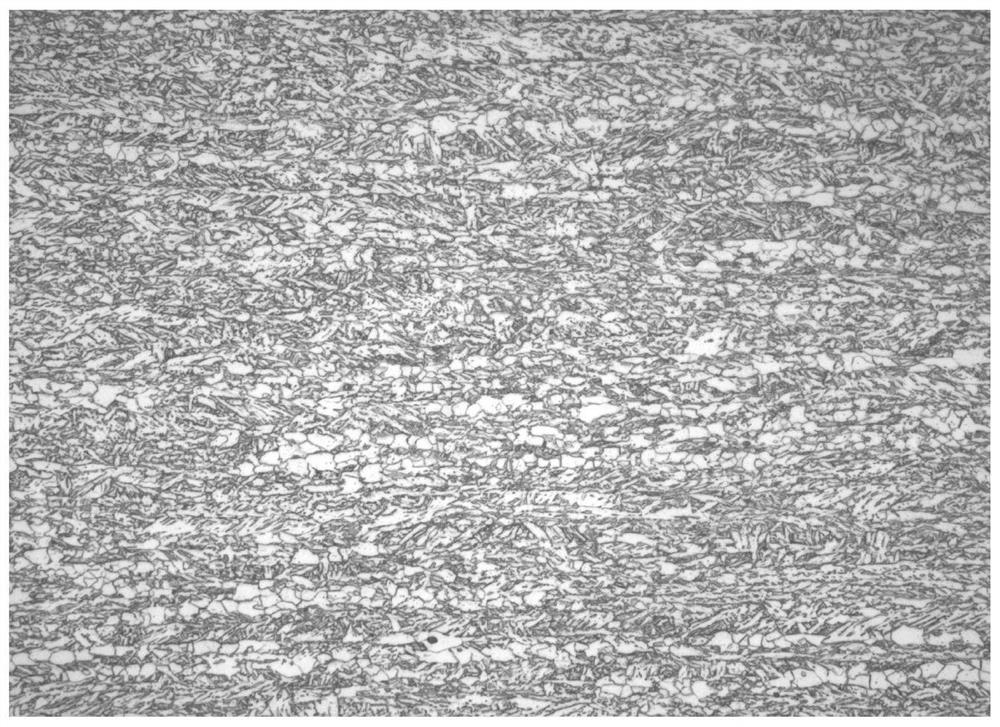

Embodiment 1

[0032] The chemical compositions were included (in wt%): C: 0.08%, Si: 0.35%, Mn: 1.45%, Nb: 0.025%, Ti 0.018%, Cr: 0.35%, Mo: 0.25%, Als: 0.035% , P: 0.012%, S: 0.003%, CEV: 0.44%, the rest is Fe and inevitable impurities 300mm × 2300mm continuous casting billet reheated to 1205 ℃, in the furnace for 5.5 hours. After being released from the furnace, it enters the rough rolling mill for 3 passes of cross-rolling in the high temperature area, and starts rolling at 1140 °C. The steel billet is cooled to below 1000°C, and the cross-rolling method is continued to widen for 2 passes to reach the gross width of the steel plate above 4100mm. At this time, the thickness of the rolled piece is 167mm, and the rolling pass interval is more than 100 seconds; The temperature is sent to the finishing mill at a rolling speed of 3-3.5m / s to form a 85mm steel plate. After rolling, the water cooling temperature was controlled at 710°C, and the cooling rate was 25°C / s to 300°C. Then, the water...

Embodiment 2

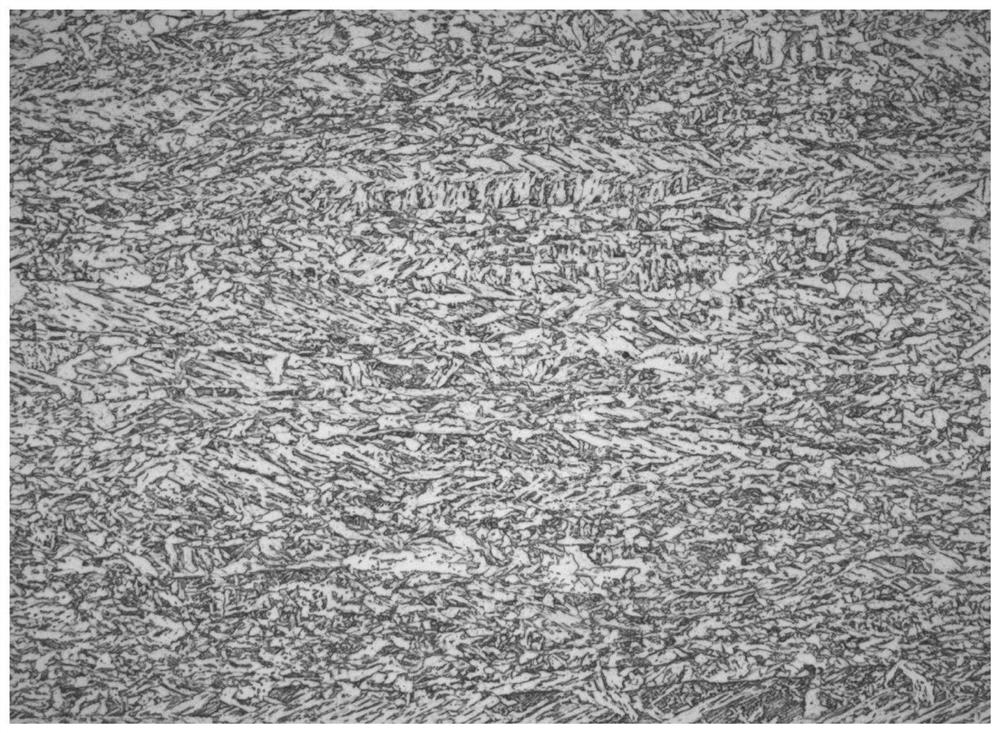

[0034]The chemical compositions were included (in wt%): C: 0.05%, Si: 0.20%, Mn: 1.52%, Nb: 0.055%, Ti 0.025%, Cr: 0.25%, Mo: 0.20%, Als: 0.032% , P: 0.010%, S: 0.005%, CEV: 0.39%, the rest is Fe and unavoidable impurities 300mm × 2200mm continuous casting billet reheated to 1220 ° C, in the furnace for 5.8 hours. After being released from the furnace, it enters the rough rolling mill for 2 passes of cross-rolling in the high temperature area, starts rolling at 1120 °C, and controls the rolling speed at 1.2-1.8m / s. The rolling at this stage ends at 1080 °C, and the thickness of the rolled piece is 225mm; The steel billet is cooled to below 980°C, and the cross-rolling method is continued to widen for 2 passes to reach the gross width of the steel plate above 3600mm. At this time, the thickness of the rolled piece is 180mm, and the rolling pass interval is more than 120 seconds; The temperature is sent to the finishing mill at a rolling speed of 3.2-4m / s to form a 90mm steel pl...

Embodiment 3

[0036] The chemical compositions are included (in wt%): C: 0.04%, Si: 0.50%, Mn: 1.20%, Nb: 0.070%, Ti 0.010%, Cr: 0.40%, Mo: 0.10%, Als: 0.15% , P: 0.014%, S: 0.008%, CEV: 0.47%, the rest is Fe and inevitable impurities 270mm × 2250mm continuous casting slab reheated to 1180 ℃, in the furnace for 6.0 hours. After being released from the furnace, it enters the rough rolling mill for 4 passes of cross-rolling in the high temperature area, and starts rolling at 1150 °C. The billet is cooled to below 990°C, and the cross-rolling method is continued to widen 4 passes to reach the gross width of the steel plate above 3800mm. At this time, the thickness of the rolled piece is 156mm, and the rolling pass interval is more than 100 seconds; The temperature is sent to the finishing mill at a rolling speed of 2.8-3.4m / s to form a 80mm steel plate. After rolling, the water cooling temperature was controlled at 730°C, and cooled to 340°C at a rapid cooling rate of 28°C / s. Then, the water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com