Aluminum silicon alloy welding wire suitable for manufacturing wire additional material

An aluminum-silicon alloy and additive manufacturing technology, applied in manufacturing tools, welding media, welding equipment, etc., can solve problems such as the inability to give full play to the characteristics of the alloy manufacturing process, and achieve the effects of excellent appearance quality, uniform organization, and clean internal quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The invention provides an aluminum-silicon alloy welding wire suitable for wire material additive manufacturing, the preparation steps of which are as follows:

[0050] (1) Raw material configuration: Al: 118kg, Si: 9.10kg, Mg: 0.78kg, AlTi10: 1.56, AlLa30: 0.13kg, AlSr10: 0.39kg are melted and alloyed in an intermediate frequency furnace, and the melting temperature is controlled at 750± 10°C, the feeding sequence is: Al—Si—AlLa30—AlSr10—AlTi10—Mg, and the gap between each two alloy materials should not be less than 3 minutes;

[0051] (2) After smelting, the aluminum alloy melt is subjected to inert gas rotary injection refining and secondary vacuum refining. During the refining process, the temperature of the aluminum melt is controlled at 750°C±10°C, and the inert gas is 99.999% Ar.

[0052] (3) The refined aluminum alloy melt is kept at 720°C±10°C in an inert gas-protected resistance furnace and continuously cast into a disc with a diameter of 12mm±1mm, and the cas...

Embodiment 2

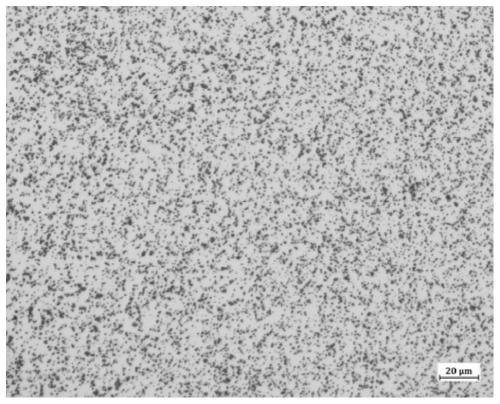

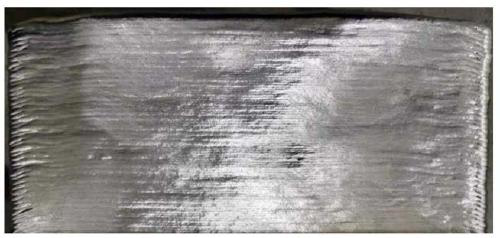

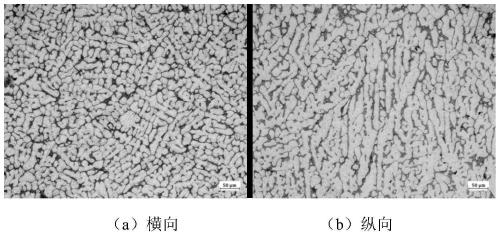

[0059] Using the welding wire prepared in Example 1 as the raw material, the stacking was carried out by CMT additive process at room temperature. The accumulation process is well formed, and the appearance of the accumulation body is as follows figure 2 shown. The directly formed accumulation structure has smaller primary dendrite spacing (DAS) and secondary dendrite arm spacing (SDAS), and the second phase particles such as eutectic silicon are distributed among the dendrite arms, such as image 3 shown. After T6 heat treatment, the eutectic silicon is fully spheroidized, the second phase particles are evenly distributed in the matrix, and the dendrites are all eliminated, as shown in Figure 4 shown.

[0060] The mechanical properties of the accumulated body after T6 heat treatment were tested at room temperature and 200°C / 30min, and the results are shown in Table 1.

[0061] Table 1 The mechanical properties of the accumulation body of the present invention and compar...

Embodiment 3

[0065] The invention is an aluminum-silicon alloy welding wire suitable for wire material additive manufacturing. The alloy composition is calculated by mass percentage: silicon Si: 6.98, magnesium Mg: 0.61, titanium Ti: 0.12%, strontium Sr: 0.030%, lanthanum La: 0.028 %, iron Fe: 0.08, and the balance is aluminum Al.

[0066] Prepared according to the processing method described in the invention The processing process is smooth, and the finished product rate reaches 92%. The welding wire is used as filler for welding, and the weld seam grade reaches Class I, and the welding strength coefficient is more than 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com