High-uniform longitudinal-and-transverse toughness wide-width steel plate and TMCP process production method thereof

A production method and vertical and horizontal technology, which are applied in the production field of high-uniform vertical and horizontal toughness wide-width steel plates and their TMCP process, can solve the problems of long process, high energy consumption, supporting special equipment, etc., and achieve uniform performance and uniform texture distribution. , the effect of reducing the effect of the difference in horizontal and vertical deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

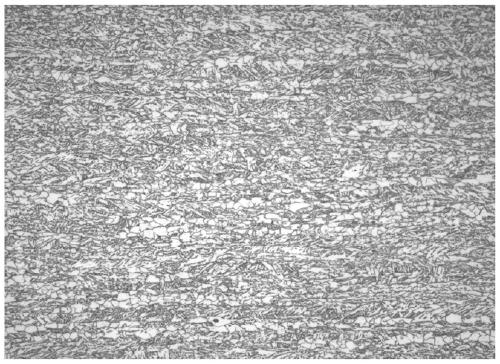

[0032] The chemical composition includes (by weight%): C: 0.08%, Si: 0.35%, Mn: 1.45%, Nb: 0.025%, Ti0.018%, Cr: 0.35%, Mo: 0.25%, Als: 0.035% , P: 0.012%, S: 0.003%, CEV: 0.44%, and the rest is Fe and unavoidable impurities. The 300mm×2300mm continuous casting slab is reheated to 1205°C for 5.5 hours in the furnace. After coming out of the furnace, enter the rough rolling mill for 3 passes of cross rolling in the high temperature zone, start rolling at 1140°C, and control the rolling speed at 1.8-2.2m / s. The rolling at this stage ends at 1100°C, and the thickness of the rolled piece is 210mm at this time; The steel billet is cooled below 1000°C, and continues to be widened by cross rolling for 2 passes to reach a steel plate with a rough width of more than 4100mm. At this time, the thickness of the rolled piece is 167mm, and the interval between rolling passes is more than 100 seconds; ℃ into the finish rolling mill at a rolling speed of 3-3.5m / s to quickly longitudinally rol...

Embodiment 2

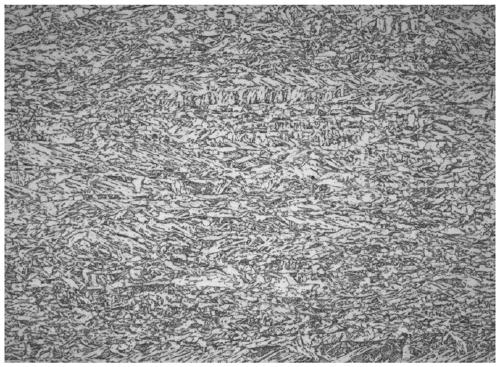

[0034]The chemical composition includes (by weight%): C: 0.05%, Si: 0.20%, Mn: 1.52%, Nb: 0.055%, Ti0.025%, Cr: 0.25%, Mo: 0.20%, Als: 0.032% , P: 0.010%, S: 0.005%, CEV: 0.39%, and the rest is Fe and unavoidable impurities. The 300mm×2200mm continuous casting slab is reheated to 1220°C for 5.8 hours in the furnace. After being out of the furnace, enter the rough rolling mill for 2 passes of cross rolling in the high temperature zone, start rolling at 1120°C, and control the rolling speed at 1.2-1.8m / s. The rolling at this stage ends at 1080°C, and the thickness of the rolled piece is 225mm at this time; The steel billet is cooled to below 980°C, and continues to be widened by cross rolling for 2 passes to reach a steel plate with a rough width of more than 3600mm. At this time, the thickness of the rolled piece is 180mm, and the interval between rolling passes is more than 120 seconds; ℃ into the finish rolling mill at a rolling speed of 3.2-4m / s to quickly longitudinally rol...

Embodiment 3

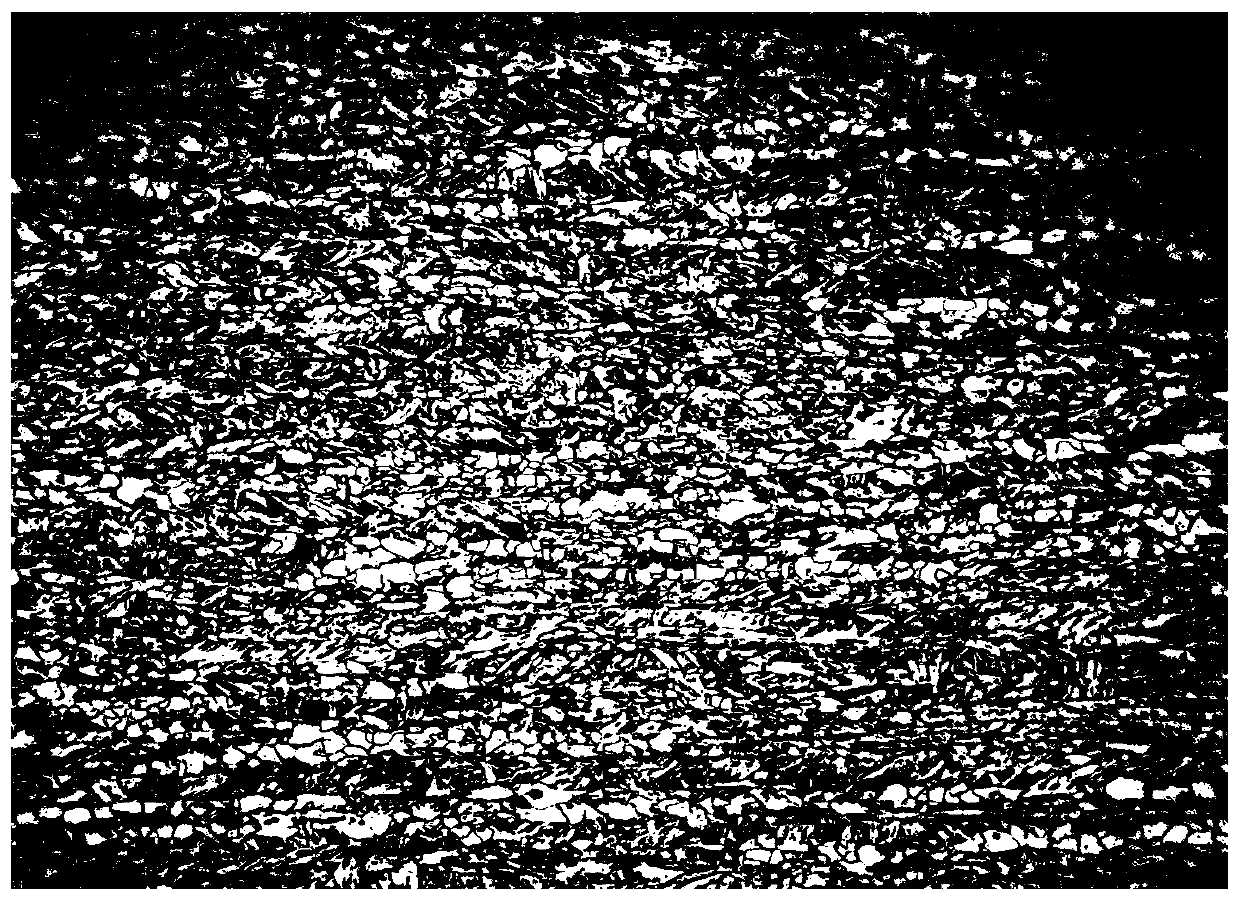

[0036] The chemical composition includes (by weight%): C: 0.04%, Si: 0.50%, Mn: 1.20%, Nb: 0.070%, Ti0.010%, Cr: 0.40%, Mo: 0.10%, Als: 0.15% , P: 0.014%, S: 0.008%, CEV: 0.47%, and the rest is Fe and unavoidable impurities. The 270mm×2250mm continuous casting slab is reheated to 1180°C for 6.0 hours in the furnace. After being out of the furnace, enter the rough rolling mill for 4 passes of cross rolling in the high temperature zone, start rolling at 1150°C, and control the rolling speed at 1.0-1.6m / s. The rolling at this stage ends at 1110°C, and the thickness of the rolled piece is 200mm at this time; The steel billet is cooled to below 990°C, and continues to be widened by cross rolling for 4 passes to reach a steel plate with a rough width of more than 3800mm. At this time, the thickness of the rolled piece is 156mm, and the interval between rolling passes is more than 100 seconds; ℃ into the finish rolling mill at a rolling speed of 2.8-3.4m / s to quickly longitudinally r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com